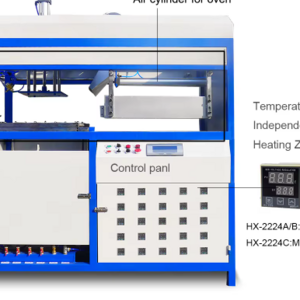

Digital Temperature controller

30 pieces of ceramic infrared heater can be controlled separately.Digital controller,set in the DELTA PLC,one time setting or separate setting for option,easy to adjust the temperature than outer individual temp.controller.This second generation machine is more stable and good performance.