- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ocean

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1290*1075*1740

-

Power (kW):

-

15

-

Weight (T):

-

0.5

-

Name:

-

Plastic Shredder

-

Usage:

-

Waste Plastic Cusher

-

Function:

-

Plastic Cutter plastic shredder machine

-

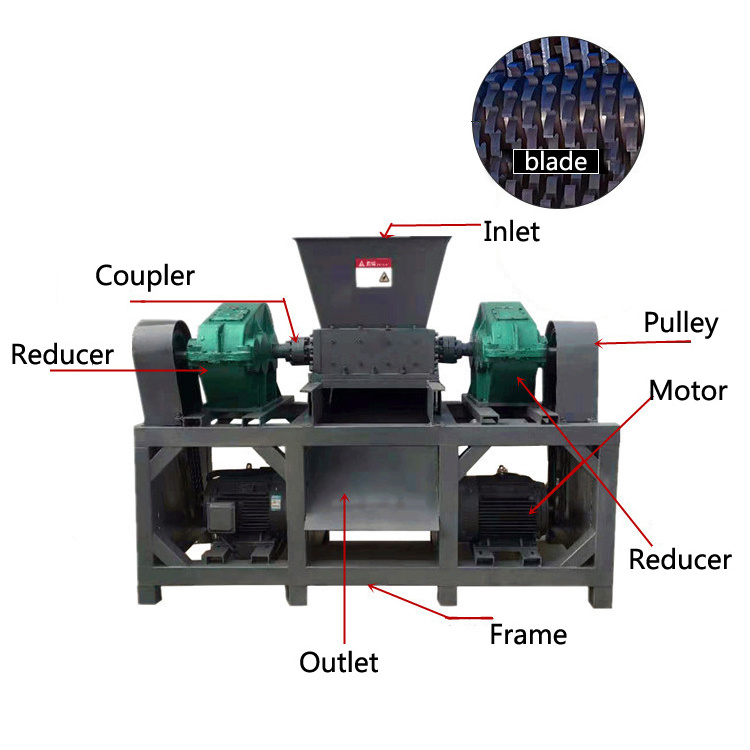

Type:

-

Two Shaft scrap metal steel shredder machine

-

Crushing material:

-

General Plastic Materials

-

Material:

-

Steel Iron plastic shredder machine

-

Application:

-

Recycled Industry

-

Motor power:

-

15-110kw plastic shredder machine

-

Machine:

-

Double Shaft Shedder

-

Suitable material:

-

Waste Rubbish

Quick Details

-

Max.Production Capacity (kg/h):

-

17000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

800 - 26000 kg/h

-

Brand Name:

-

Ocean

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1290*1075*1740

-

Power (kW):

-

15

-

Weight (T):

-

0.5

-

Name:

-

Plastic Shredder

-

Usage:

-

Waste Plastic Cusher

-

Function:

-

Plastic Cutter plastic shredder machine

-

Type:

-

Two Shaft scrap metal steel shredder machine

-

Crushing material:

-

General Plastic Materials

-

Material:

-

Steel Iron plastic shredder machine

-

Application:

-

Recycled Industry

-

Motor power:

-

15-110kw plastic shredder machine

-

Machine:

-

Double Shaft Shedder

-

Suitable material:

-

Waste Rubbish

Industrial metal shredder single shaft shredder plastic film plastic shredder machine

Product Description

1. The knife holder and blade on the rotor are removable for easy cleaning, maintenance and maintenance.

2. Each movable knife has 4 cutting edges, which can be rotated 90° to continue use after wear.

3. The main shaft is driven by a gear reducer, running smoothly, with low noise and large torque

4. Adopt PLC program control system, can automatically forward and reverse, make the machine ru.n stably

5. The box body is welded and tempered after welding.

6. The movable tool holder is connected to the tool shaft with screws in an embedded way, which can avoid the phenomenon of tool drop caused by welding after long-term vibration.

7. After shredding, the transportation is convenient, the transportation cost is low, the transportation efficiency is increased,and the second treatment is convenient.

2. Each movable knife has 4 cutting edges, which can be rotated 90° to continue use after wear.

3. The main shaft is driven by a gear reducer, running smoothly, with low noise and large torque

4. Adopt PLC program control system, can automatically forward and reverse, make the machine ru.n stably

5. The box body is welded and tempered after welding.

6. The movable tool holder is connected to the tool shaft with screws in an embedded way, which can avoid the phenomenon of tool drop caused by welding after long-term vibration.

7. After shredding, the transportation is convenient, the transportation cost is low, the transportation efficiency is increased,and the second treatment is convenient.

Specification

The shredder blade is forged, annealed, heat-treated, tempered and insulated, on-line cutting and fine grinding.

Gearbox adopts steel welding precision

High, good contact, low voice

long lasting.

3.Copper core motor

Power surging,Strong power comes from a good motor,Durable,Worry-free quality, long-lasting operationMute and low noise,Tai Chi turbine impeller rotates,Can effectively reduce noise.

The transmission parts of the shredder are linked by couplings to reduce vibration.Protect the spindle and reducer without damaging force.

5.Selected raw materials

Selected hard alloy powder, high temperature after precision molding

High hardness, sharp cutting edge, good wear resistance, ordinary blade

Product Paramenters

Hot Searches