- Product Details

- {{item.text}}

Quick Details

-

Dimensions:

-

4500*1800*1750mm

-

Current:

-

50HZ

-

Weight (KG):

-

800 KG

-

Product name:

-

reflow oven machine

-

Function:

-

Lead Free Welding

-

Package:

-

Wooden Case

-

Delivery:

-

Within 25 Days

-

advantage:

-

environmental welding

-

keyword:

-

heat transfer technology

-

MOQ:

-

1set

-

Service:

-

OEM/ODM

Quick Details

-

Applicable Industries:

-

smt machine

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

220V, 220V

-

Dimensions:

-

4500*1800*1750mm

-

Current:

-

50HZ

-

Weight (KG):

-

800 KG

-

Product name:

-

reflow oven machine

-

Function:

-

Lead Free Welding

-

Package:

-

Wooden Case

-

Delivery:

-

Within 25 Days

-

advantage:

-

environmental welding

-

keyword:

-

heat transfer technology

-

MOQ:

-

1set

-

Service:

-

OEM/ODM

Desktop small soldering reflow oven for SMT electronics production

Features

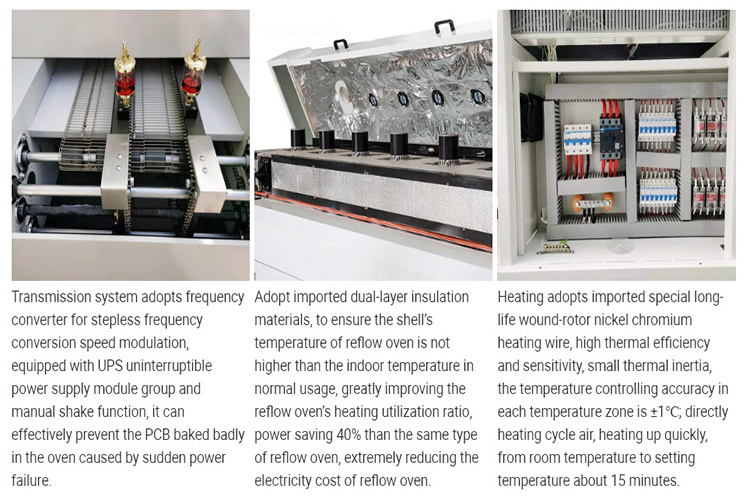

2.This machine is equipped with the crawler-type conveyor and 5 temperature zones heating systems.Each zone uses independent PID controlling and up-down heating type,can make the inside temp more accurate and well-proportioned.About 15 minutes can let it heat up to the working temp.

3.Intelligent temperature curve heating type, oversized capacity curve selection. Editable 8 temp curves can satisfy various welding technological requirements.

4.By using programmable technology, presetting the temperature curve memory storage function, can complete the whole welding process automatically.

5.Clear lcd screen, which integrates machine operation and function display, making the working state display more intuitive,heating process more clear, and operation more convenient.

6.Adopts the thermocouple temperature measurement and adds the compensation circuit,

makes the temperature measurement more accurate, the curve more perfect.

7.Using PID intelligent temperature control technology, makes the temp control more accurate.The imported large current solid-state relays can effectively avoid the IC or circuit boards being damaged due to the rapid or uninterrupted warming up.

Product parameters:

Products Specifications:

|

Model |

A8 |

|

Heating Zone |

Upper 8 / Down 8 zones |

|

Heating Zone Length |

3150mm |

|

Heating Method |

Full hot air |

|

Cooling Zone |

2 Zone |

|

Cooling Method |

Forced Air Cooling |

|

Max. PCB Width |

300mm |

|

Mesh Width |

450mm |

|

Transmission Belt Height |

880 ± 20mm |

|

Transmission Speed |

0-2000mm/min |

|

Transmission Type |

Mesh Transmission +Rail guide+PC control |

|

Transport Direction |

Left→right (right→left optional) |

|

Power |

3-phase 380V |

|

Starting Power |

32KW |

|

Working Power |

Appro 5KW |

|

Warm-up Time |

about 15~20 minutes |

|

Temperature Range |

Room temperature to 400ºC |

|

Temperature Control Accuracy |

±2ºC |

|

Temperature Distribution Deviation |

±2ºC |

|

Temperature Control Type |

Industrial PC + PLC |

|

Abnormal Alarm |

Temperature abnormal (ultra-high or ultra-low temperature) |

|

Dimensions |

4600*1000*1420mm |

|

Weight |

1100kg |