- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

other

-

Model Number:

-

UV varnish for car headlight

-

Chemical name:

-

Headlight Restoration Renew Polymer Headlight Cleaner Restore Coating

-

Adhesive force( cross cut test):

-

100/100

-

Glossiness:

-

≥95

-

Viscosity:

-

18s±1

-

Hardness( pencil hardness):

-

9H

-

Application:

-

car, headlight repairing

-

Color:

-

Colorless

-

Curing speed:

-

≤ 8 s

-

Feature:

-

High Gloss

-

Certification:

-

COA

Quick Details

-

CAS No.:

-

367432

-

Other Names:

-

uv coating

-

MF:

-

other

-

EINECS No.:

-

other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

other

-

Model Number:

-

UV varnish for car headlight

-

Chemical name:

-

Headlight Restoration Renew Polymer Headlight Cleaner Restore Coating

-

Adhesive force( cross cut test):

-

100/100

-

Glossiness:

-

≥95

-

Viscosity:

-

18s±1

-

Hardness( pencil hardness):

-

9H

-

Application:

-

car, headlight repairing

-

Color:

-

Colorless

-

Curing speed:

-

≤ 8 s

-

Feature:

-

High Gloss

-

Certification:

-

COA

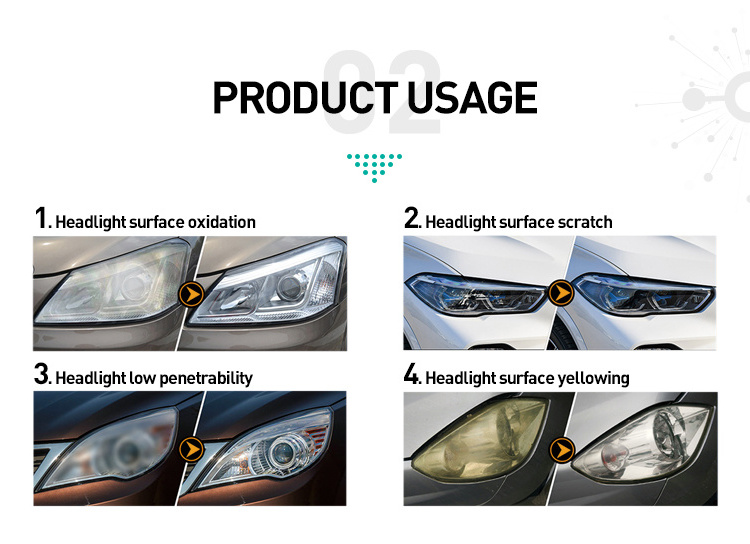

Headlight Restoration Renew Polymer Headlight Cleaner Restore Coating

Product information

Parameter of Headlight Restoration Renew Polymer Headlight Cleaner Restore Coating

|

Item |

Specification |

|

Appearance |

Clear and transparent liquid |

|

Viscosity(Tu-4 cup) |

18s±1 |

|

Curing speed |

≤ 8 s |

|

Solid content |

96% |

|

Glossiness ( glossmeter) |

≥95 |

|

Adhesive force( cross cut test) |

100/100 |

|

Hardness( pencil hardness) |

9H |

|

High temperature resistance(120℃,2 h) |

No color change,no crack |

|

Yellowing resistance(1000wultraviolet radiator, 1h) |

No yellowing, no come -off |

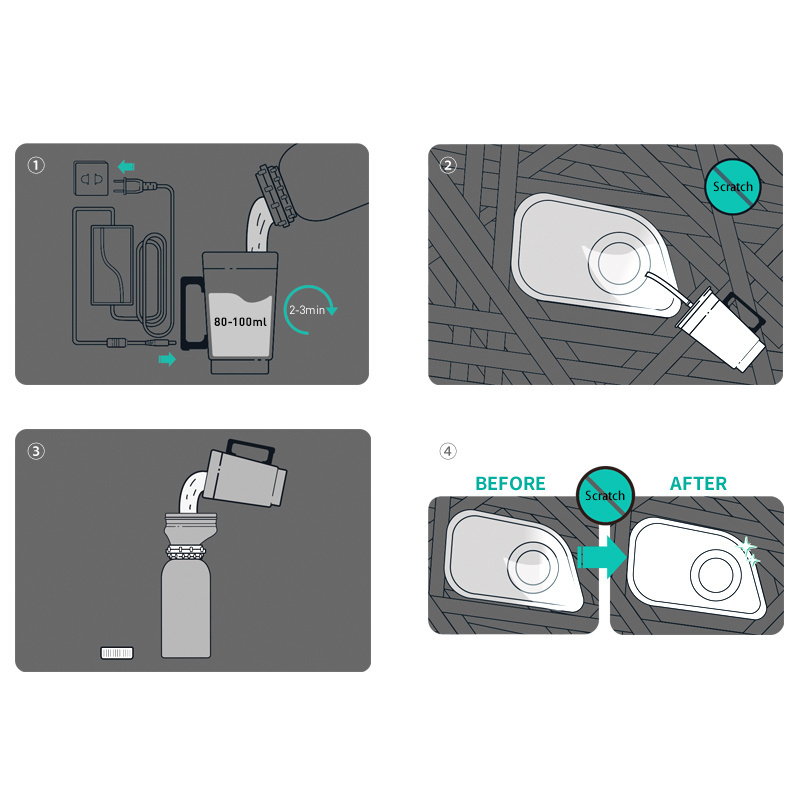

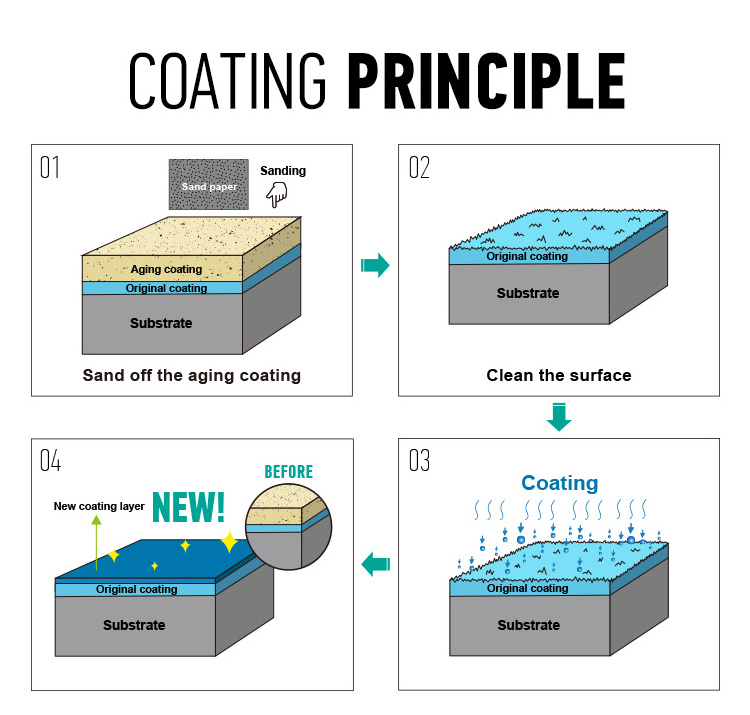

Application tips of Headlight Restoration Renew Polymer Headlight Cleaner Restore Coating

1. Clean the surface of the lamp with clean towel, and put 2-3 layers of fine paper on the periphery of the headlights to prevent the car paint from being wrong polished.

Sandpaper introduction: 150 #-180 # severe cracks and scratches are used (generally mild yellow or slightly cracked, do not use) 240# Slightly cracked or yellowish to use (slightly cracked or peeling) 320# slightly yellowing or dealing with the sand paper mark left on 240 # (manual polishing can be directly used by 320# manual grinding) 500 # mainly deals with the sandpaper left by 320 #. 800 # mainly deals with the sand paper mark of 500 #. After polishing, it can be directly used for fumigation repair. If you want to fix it better. You can use 1200 # for a simple grind, but remember, you can use 1500 # or 2000 # to fine polish the headlights, because the polishing is too smooth and the brightness is not high enough.

2. There are two main methods for the polishing of headlamps. One is the grinding of the machine, and the another way is the manual polishing. In this case, we give you a brief introduction to the manual polishing method.

Package and delivery of Headlight Restoration Renew Polymer Headlight Cleaner Restore Coating

1. Liquid: 800g one bottle, 25bottles one carton

2.Set: 1 set per carton, 10sets per box