- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

Genuo

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

7200 KG

-

Place of Origin:

-

Anhui

-

Voltage:

-

220v/380v/400v

-

Dimension(L*W*H):

-

3860*1700*1720

-

Year:

-

2023

-

Marketing Type:

-

New Product 2023

-

Cutting mode:

-

Guillotinas Cutting Machine

-

Application:

-

Metal Sheet Cutting

-

CNC or not:

-

CNC Cutter Machine

-

Control system:

-

Estun E21 NC Control

-

Hydraulic System:

-

Rexroth Germany

-

Main Motor:

-

Siemens Germany

-

Cutting length:

-

2500-6000mm

-

Electrical components:

-

Schneider Electrical

-

Color:

-

Customer Requirement

-

Max thickness:

-

1-2 Mm

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

8 mm

-

Shearing Angle:

-

2

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

Genuo

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

7200 KG

-

Place of Origin:

-

Anhui

-

Voltage:

-

220v/380v/400v

-

Dimension(L*W*H):

-

3860*1700*1720

-

Year:

-

2023

-

Marketing Type:

-

New Product 2023

-

Cutting mode:

-

Guillotinas Cutting Machine

-

Application:

-

Metal Sheet Cutting

-

CNC or not:

-

CNC Cutter Machine

-

Control system:

-

Estun E21 NC Control

-

Hydraulic System:

-

Rexroth Germany

-

Main Motor:

-

Siemens Germany

-

Cutting length:

-

2500-6000mm

-

Electrical components:

-

Schneider Electrical

-

Color:

-

Customer Requirement

-

Max thickness:

-

1-2 Mm

Products Description

GENUO has rich production experience and technology in shearing cutting

machines,

we began to produce the simplest hydraulic metal sheet cutter many

years ago, and

now we provide hydraulic metal cutting machines manufactured

in our world-class

manufacturing facilities.

Through continuous innovation and solution orientation,

our existing shears

around the world have made some suggested adjustments.

Both swing beam type and guillotine type plate shears can bring you simple and

efficient sheet metal cutting.In recent years, various cutting machines for metal

sheet are popular. But we have not stopped the pace of innovation.

sheet are popular. But we have not stopped the pace of innovation.

The new

generation of hybrid

low energy consumption and noise CNC plate

shears

will be

one of your indispensable choices.

|

Standard Equipment

|

Optional Equipment

|

|

■ ESTUN E21S NC control

|

□ E200PS/ CybTouch 8/ DAC-360T CNC control

|

|

■ Shilin stepping motor frequency converter

|

□ Sheet support system for thin sheets

|

|

■ Back gauge with roll guide and ball screw

|

□ Energy saving main servo motor pump system

|

|

■ SIEMENS main motor, Schneider electric

|

□ Moveable controller panel,Wireless foot pedal

|

|

■ Sunny pump,Rexroth hydraulic valve

|

□ Hydraulic oil cooling and heating system

|

|

■ EMB ferrule type pipe connector,NOK sealing rings

|

□ Automatic blade gap adjustment device

|

|

■ Roller bearings on the front support table

|

□ Front angle gauge and side gauge

|

|

■ Sheet sliding system and front support arms

|

□ Light safety system for finger protection

|

|

■ Collapsible guardrail finger protection

|

□ 4~40mm thickness,1.6~6M length optional

|

To Learn More

Click Here >>

E21S(ESTUN)

Backgauge control;

Control ordinary motors or inverters;

Intelligent posi- tioning;

Dual programmable digital output;

Workpiece count; 40 program

storage, Each program has 25

steps;Unilateral positioning;

Metric system.Yield function;

One-key backup and restore of

parameters;

E200PS(ESTUN)

CAN bus control X axis sevo;Shear

control;Dual programmable digital

output;40 program storage, each

program has 25 steps; Unilateral

positioning;Built-in cutting time,

retreat delay; One-key backup and

restore of parameters; Full-function

online diagnosis, real-time alarm

prompt Reserve a safe, supporting

material interface;

Color LCD HD display;

Metric/English;Chinese-English.

output;40 program storage, each

program has 25 steps; Unilateral

positioning;Built-in cutting time,

retreat delay; One-key backup and

restore of parameters; Full-function

online diagnosis, real-time alarm

prompt Reserve a safe, supporting

material interface;

Color LCD HD display;

Metric/English;Chinese-English.

CybTouch 8 G(CYBELEC)

High-contrast touchscreen,

with vivid colors.Simple pages,

large keys, clear display with all

the information the operator

needs. Intuitive and user-

friendly interface.Complete

programming of parts in seconds.

Quick set up of the machine with

the EasyCut page.Contextual

help and waming pop-up.

needs. Intuitive and user-

friendly interface.Complete

programming of parts in seconds.

Quick set up of the machine with

the EasyCut page.Contextual

help and waming pop-up.

DAC-360T (Delem)

Panel based housing;Bright LCD

screen;Back / front gauge

control; Retract function;

Cutting angle and gap control;

Stroke length limitation;

Manual movement of all axes;

Force control;Sheet thickness

measurement;

Retum to Sender function;

Sheet support.

control; Retract function;

Cutting angle and gap control;

Stroke length limitation;

Manual movement of all axes;

Force control;Sheet thickness

measurement;

Retum to Sender function;

Sheet support.

Powerful frame & robust design for perfect cutting.Hardened and ground blades for long

life

and precise Proved and rigid design with swing beam top table Minimum deformation

and

optimum cutting quality with best cutting angle CE standards security.

The combination of economic and perfect cutting performance CNC controlled gap adjust

-ment

and cutting angle. Adopt friendly CNC touch screen control unit Provide flexible use

for narrow

or wide, thin or thick sheet metal cutting.

Automatic swing up back gauge for more comfortable use.Sheet support arms Balls

trarifered table and T-slot front feedings arm helps pieces cutting.Table with balls and

feeding plates.

Hydraulic Hold downs

Built-in spring structure,

where the lower part with

special materal gasketstoad

leing trace line On aluminum

alloy or other sensitive material .

special materal gasketstoad

leing trace line On aluminum

alloy or other sensitive material .

Shear Blades

High Precision Ball Screw,Made using

special alloy steel according to the

customer's needs: material to be cut,

holes & hardening.suitable to guarantee

reliability & wear resistance.

customer's needs: material to be cut,

holes & hardening.suitable to guarantee

reliability & wear resistance.

The machine can be equipped with 9CrSi,

6CrW2Si and SKD-11 all steel shear blade.

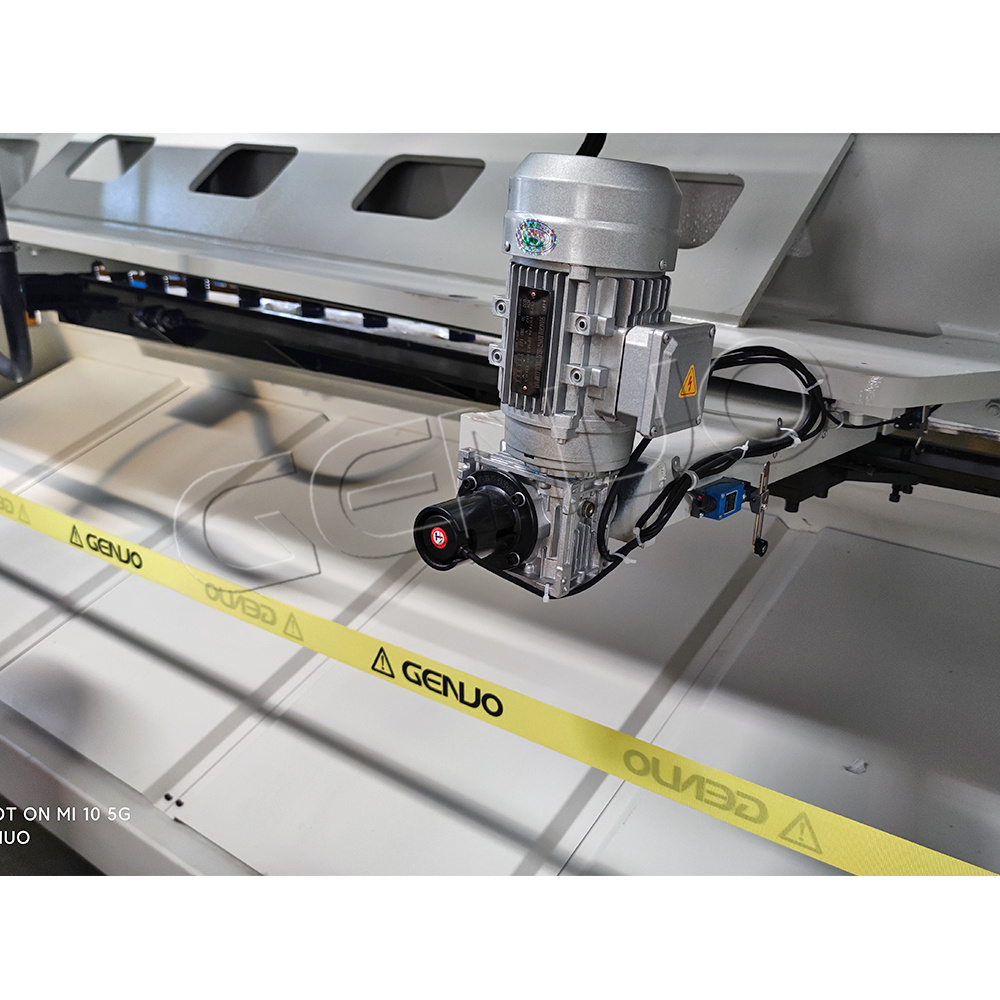

Backgauge Motor

The backgauge stopper is equipped with high-

quality drive motor to run at a higher speed and

stably.Optional servo motor.

stably.Optional servo motor.

Fast Blade Gap Adjustment Device

Simple and quick manual adjustment, the

implementation of the blade gap adjustment.

Siemens Main Motor

The powerful Siemens motor provides stable

shear force guarantee the machine service life,

and low noise in work.

and low noise in work.

EMB Bite Type Tube Fittings

Using galvanized cold drawn pipe and EMB

ferrule type pipe joint.Reduce the risk of oil

leakage by 50% compared with most machines.

Hydraulic Valve

The BOSCH (Rexroth) integrated hydraulic

system is compact. Adopts electro-hydraulic

proportional pressure valve, and the whole

proportional pressure valve, and the whole

process pressure can be programmed and

controlled to ensure machine stable .

Electrical System

Our machine adopt Schneider electrical components.

The high quality electric parts can make the machine

performing well even the electricity is not stable and

customers can easily get the replacement anywhere

customers can easily get the replacement anywhere

in the world.

Front Worktable

- Ball Transfer Table

- Hydraulic Holddowns

- Front Protection Frame

Worktable with ball to decrease the friction

and the scratch of sheet plate when feeding .

Stable Back Gauge

- Fast and high accuracy

- Reliable movement

- Adjustment from each point

- Resistance to crash

- Maintenance free

The unique and novel ball screw linear guide

structure back-gauge ensures high positioning

accuracy.

accuracy.

Adjustable beam guiding rule and synchronous transmission structure, stable and reliable .

|

Model

|

Cutting Thickness

|

Cutting Length

|

Cutting

Angle

|

Stroke

|

Main

Power

|

Approx. Weight

|

Material Intension

|

Cutting Times

|

Overall Dimension

(L x W x H)

|

|||||||||

|

Type

|

(mm)

|

(mm)

|

( ° )

|

(mm)

|

(Kw)

|

( Kg)

|

(Kn/Cm)

|

(T/Min)

|

(mm)

|

|||||||||

|

4x2500

|

4

|

2500

|

1°30‘

|

20~600

|

5.5

|

3500

|

≤450

|

16

|

3.3x1.6x1.6m

|

|||||||||

|

4x3200

|

4

|

3200

|

1°30‘

|

20~600

|

5.5

|

4500

|

≤450

|

14

|

3.8x1.6x1.6m

|

|||||||||

|

4x4000

|

4

|

4000

|

1°30‘

|

20~600

|

5.5

|

6500

|

≤450

|

10

|

4.6x1.7x1.7m

|

|||||||||

|

4x6000

|

4

|

6000

|

1°30‘

|

20~600

|

7.5

|

11000

|

≤450

|

8

|

6.5x2.1x3.2m

|

|||||||||

|

6x2500

|

6

|

2500

|

1°30‘

|

20~600

|

7.5

|

5000

|

≤450

|

14

|

3.4x1.6x1.6m

|

|||||||||

|

6x3200

|

6

|

3200

|

1°30‘

|

20~600

|

7.5

|

6000

|

≤450

|

12

|

3.8x1.6x1.6m

|

|||||||||

|

6x4000

|

6

|

4000

|

1°30‘

|

20~600

|

7.5

|

8200

|

≤450

|

8

|

4.6x1.7x1.7m

|

|||||||||

|

6x5000

|

6

|

5000

|

1°30‘

|

20~600

|

11

|

10500

|

≤450

|

6

|

5.4x1.8x1.9m

|

|||||||||

|

6x6000

|

6

|

6000

|

1°30‘

|

20~600

|

11

|

16500

|

≤450

|

5

|

6.5x2.1x2.3m

|

|||||||||

|

8x2500

|

8

|

2500

|

1°30‘

|

20~600

|

7.5

|

6000

|

≤450

|

10

|

3.4x1.7x1.7m

|

|||||||||

|

8x3200

|

8

|

3200

|

1°30‘

|

20~600

|

7.5

|

7200

|

≤450

|

8

|

3.9x1.7x1.7m

|

|||||||||

|

8x4000

|

8

|

4000

|

1°30‘

|

20~600

|

7.5

|

8800

|

≤450

|

8

|

4.6x1.7x1.7m

|

|||||||||

|

8x5000

|

8

|

5000

|

1°40‘

|

20~600

|

11

|

11500

|

≤450

|

8

|

5.4x2.1x2.0m

|

|||||||||

|

8x6000

|

8

|

6000

|

1°40‘

|

20~600

|

11

|

18000

|

≤450

|

8

|

6.5x2.1x2.4m

|

|||||||||

|

10x2500

|

10

|

2500

|

2°

|

20~600

|

11

|

7300

|

≤450

|

9

|

3.4x1.7x1.7m

|

|||||||||

|

10x3200

|

10

|

3200

|

2°

|

20~600

|

11

|

8000

|

≤450

|

9

|

3.9x1.7x1.7m

|

|||||||||

|

10x4000

|

10

|

4000

|

2°

|

20~600

|

11

|

12050

|

≤450

|

8

|

4.7x2.1x2.0m

|

|||||||||

|

10x6000

|

10

|

6000

|

2°

|

20~1000

|

15

|

2400

|

≤450

|

5

|

6.5x2.1x2.3m

|

|||||||||

|

12x2500

|

12

|

2500

|

2°

|

20~600

|

18.5

|

9000

|

≤450

|

9

|

3.5x2.2x2.0m

|

|||||||||

|

12x3200

|

12

|

3200

|

2°

|

20~600

|

18.5

|

10800

|

≤450

|

9

|

3.9x2.2x2.0m

|

|||||||||

|

12x4000

|

12

|

4000

|

2°

|

20~1000

|

18.5

|

13000

|

≤450

|

8

|

4.7x2.2x2.0m

|

|||||||||

|

12x5000

|

12

|

5000

|

2°

|

20~1000

|

18.5

|

16000

|

≤450

|

6

|

5.9x2.2x2.0m

|

|||||||||

|

12x6000

|

12

|

6000

|

2°

|

20~1000

|

18.5

|

29500

|

≤450

|

5

|

6.9x2.6x2.7m

|

|||||||||

|

16x2500

|

16

|

2500

|

2°20’

|

20~600

|

22

|

11000

|

≤450

|

9

|

3.5x2.2x2.0m

|

|||||||||

|

16x3200

|

16

|

3200

|

2°20’

|

20~600

|

22

|

13000

|

≤450

|

8

|

3.9x2.2x2.0m

|

|||||||||

|

16x4000

|

16

|

4000

|

2°20’

|

20~1000

|

22

|

16300

|

≤450

|

8

|

4.7x2.2x2.2m

|

|||||||||

|

16x5000

|

16

|

5000

|

2°20’

|

20~1000

|

22

|

20000

|

≤450

|

6

|

5.9x2.6x2.7m

|

|||||||||

|

16x6000

|

16

|

6000

|

2°20’

|

20~1000

|

22

|

36000

|

≤450

|

5

|

6.9x2.7x2.7m

|

|||||||||

|

20x2500

|

20

|

2500

|

2°30’

|

20~1000

|

22

|

15800

|

≤450

|

8

|

3.6x2.3x2.5m

|

|||||||||

|

20x3200

|

20

|

3200

|

2°30’

|

20~1000

|

22

|

18500

|

≤450

|

8

|

4.2x2.4x2.7m

|

|||||||||

|

20x4000

|

20

|

4000

|

2°30’

|

20~1000

|

22

|

21500

|

≤450

|

5

|

4.9x2.6x2.7m

|

|||||||||

|

The above data is only for reference only,to prevail in kind. More specifications available. Please

click here!

|

|

|

|

|

|

|

|

|

|

|||||||||

Recommend Products

Hot Searches