- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Aluminum ore vibrating screen YK round vibrating screen

-

Material:

-

Q235/304 stainless steel

-

Maximum feeding size:

-

<200

-

Processing capacity (t/h):

-

50-300

-

Screen size:

-

10-100mm

-

Number of screen layers:

-

1-3 layers

-

Sieve mesh:

-

Polyurethane bar, casting, punching, weaving

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhouchi

-

Weight:

-

3000 KG

-

Product name:

-

Aluminum ore vibrating screen YK round vibrating screen

-

Material:

-

Q235/304 stainless steel

-

Maximum feeding size:

-

<200

-

Processing capacity (t/h):

-

50-300

-

Screen size:

-

10-100mm

-

Number of screen layers:

-

1-3 layers

-

Sieve mesh:

-

Polyurethane bar, casting, punching, weaving

Product Description

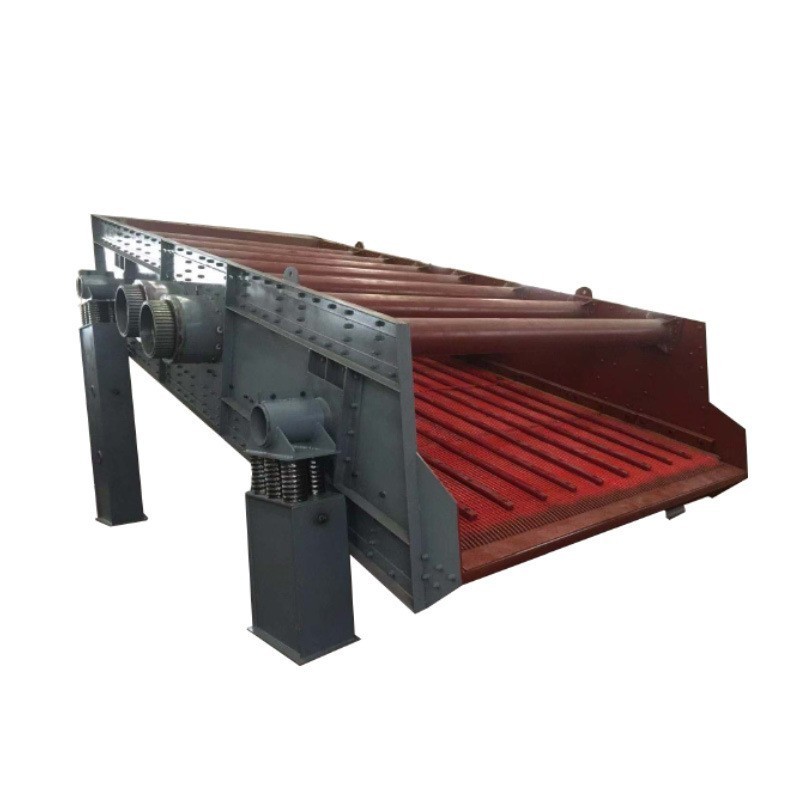

Aluminum ore vibrating screen YK round vibrating screen

1. Introduction

Aluminum vibrating screen is a kind of YK series round vibrating screen, has been widely used in bauxite, gold, mining, coal, port and other industrial sectors. The body adopts the frame structure, the use of ordinary motor to drive the vibrator to make the screen body along the direction of the vibration force for the cycle period of reciprocating vibration, the material on the screen surface continuous circular motion, so as to achieve the purpose of screening. It is a multi-layer, efficient new vibrating screen. Aluminum vibrating screen adopts cylinder type (disc type) eccentric shaft vibrator and partial block to adjust amplitude, screen plate adopts new polyurethane bar screen, material sieve flow line long, screening specifications, with reliable structure, strong vibration force, high screening efficiency, small vibration noise, durable, easy maintenance, safe use, etc..

Aluminum vibrating screen is a kind of YK series round vibrating screen, has been widely used in bauxite, gold, mining, coal, port and other industrial sectors. The body adopts the frame structure, the use of ordinary motor to drive the vibrator to make the screen body along the direction of the vibration force for the cycle period of reciprocating vibration, the material on the screen surface continuous circular motion, so as to achieve the purpose of screening. It is a multi-layer, efficient new vibrating screen. Aluminum vibrating screen adopts cylinder type (disc type) eccentric shaft vibrator and partial block to adjust amplitude, screen plate adopts new polyurethane bar screen, material sieve flow line long, screening specifications, with reliable structure, strong vibration force, high screening efficiency, small vibration noise, durable, easy maintenance, safe use, etc..

2.Structure and working principle

Aluminum vibrating screen is the use of ordinary motor outside the drag vibrator, so that the screen body along the direction of vibration force for periodic reciprocating vibration, the material on the screen surface circular motion, so as to achieve the purpose of screening.

3. Technical features and advantages

The shaker adopts block eccentric form, which not only makes the single heavy vibration force of the shaker eccentric mass increase, but also the vibration force can be randomly regulated, which is easy to modular design and use.

Screen structure is diverse, polyurethane bar sieve plate, polyurethane square hole and polyurethane braid, manganese wire braid.

The eccentric block adjusts the amplitude, the material screen line is long, the screening specification is more.

It has the characteristics of reliable structure, strong exciting force, high screening efficiency, small vibration noise, sturdy

and durable, easy maintenance, safe use and so on.

Screen structure is diverse, polyurethane bar sieve plate, polyurethane square hole and polyurethane braid, manganese wire braid.

The eccentric block adjusts the amplitude, the material screen line is long, the screening specification is more.

It has the characteristics of reliable structure, strong exciting force, high screening efficiency, small vibration noise, sturdy

and durable, easy maintenance, safe use and so on.

The equipment maintenance is simple and convenient, and the operation efficiency of the whole machine is obviously improved.

The cross shaft universal drive shaft or rubber coupling and other flexible connection, smooth running.

The structure of the screen machine tends to be simplified, which is beneficial to improve the manufacturing process level and assembly accuracy of the equipment.

Screening machine screening efficiency is higher, larger capacity, longer service cycle and machine life.

The cross shaft universal drive shaft or rubber coupling and other flexible connection, smooth running.

The structure of the screen machine tends to be simplified, which is beneficial to improve the manufacturing process level and assembly accuracy of the equipment.

Screening machine screening efficiency is higher, larger capacity, longer service cycle and machine life.

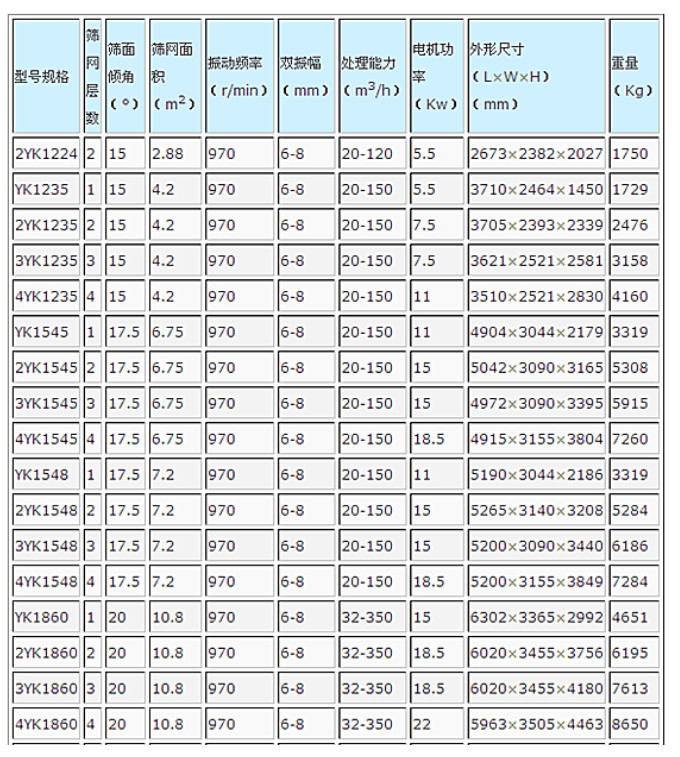

4.Technical parameters

|

Attribute name

|

Attribute data

|

Attribute name

|

Attribute data

|

|

Place of origin

|

Xinxiang, Henan

|

Model

|

YK-1536

YK-1845 YK-2460 |

|

Material

|

Q235/304 stainless steel

|

Screen size (mm*mm)

|

10-100mm

|

|

Application

|

It is used for screening metallurgy, mining, coal, port, sand, chemical and other materials. It is mainly used for classifying large and small particles and powdery particles, and for cold sinter classification operation with temperature below 150°.

|

Number of screen layers

|

1-3 layers

|

|

Maximum feeding size

|

<200

|

Screen cloth

|

Polyurethane bar, casting, punching, weaving

|

|

Processing capacity (t/h)

|

50-300

|

Application area

|

Metallurgy, petroleum, coal, mineral processing, aluminum ore, sand, mining, sinter

|

Recommend Products

Hot Searches