- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

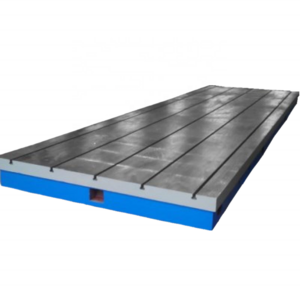

cast iron surface plate-2

-

Material:

-

cast iron, HT200-300, QT or steel

-

Accuracy:

-

customized

-

Operation Mode:

-

customized

-

Item Weight:

-

customized

-

Capacity:

-

customized

-

Product name:

-

Cast Iron Surface Plate

-

Size:

-

200x200-4000x8000mm or customize

-

Hardness:

-

HB160-240

-

Foundry process:

-

resin sand casting

-

Structure:

-

rib (bone) structure with enough wall thickness

-

Painting:

-

primer and face paint

-

Precision grade:

-

0-3

-

Working temperature:

-

(20±5) ℃

-

Packaging:

-

plywood box

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HENGFENG

-

Model Number:

-

cast iron surface plate-2

-

Material:

-

cast iron, HT200-300, QT or steel

-

Accuracy:

-

customized

-

Operation Mode:

-

customized

-

Item Weight:

-

customized

-

Capacity:

-

customized

-

Product name:

-

Cast Iron Surface Plate

-

Size:

-

200x200-4000x8000mm or customize

-

Hardness:

-

HB160-240

-

Foundry process:

-

resin sand casting

-

Structure:

-

rib (bone) structure with enough wall thickness

-

Painting:

-

primer and face paint

-

Precision grade:

-

0-3

-

Working temperature:

-

(20±5) ℃

-

Packaging:

-

plywood box

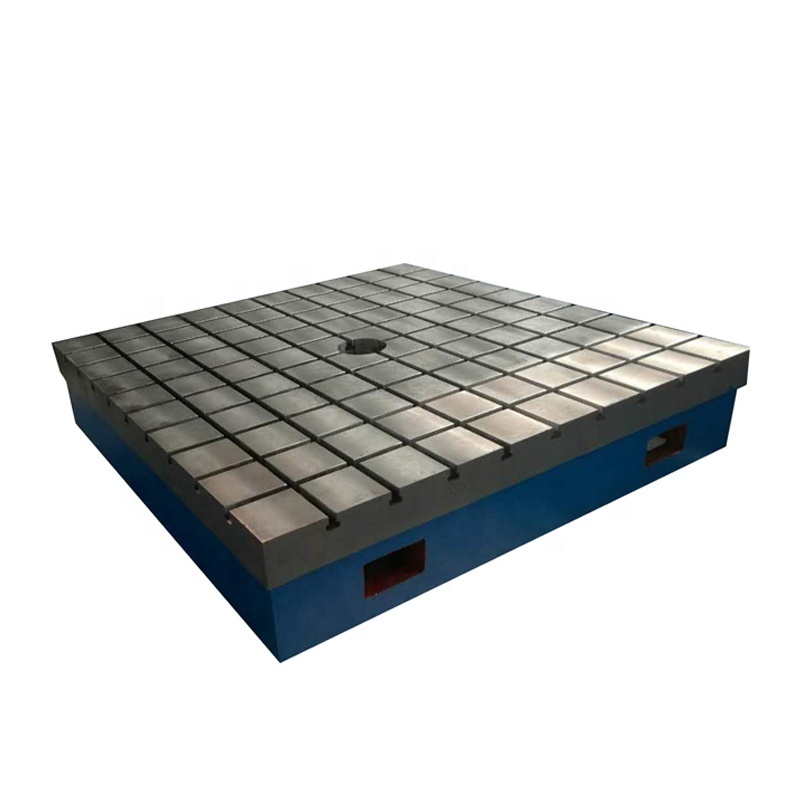

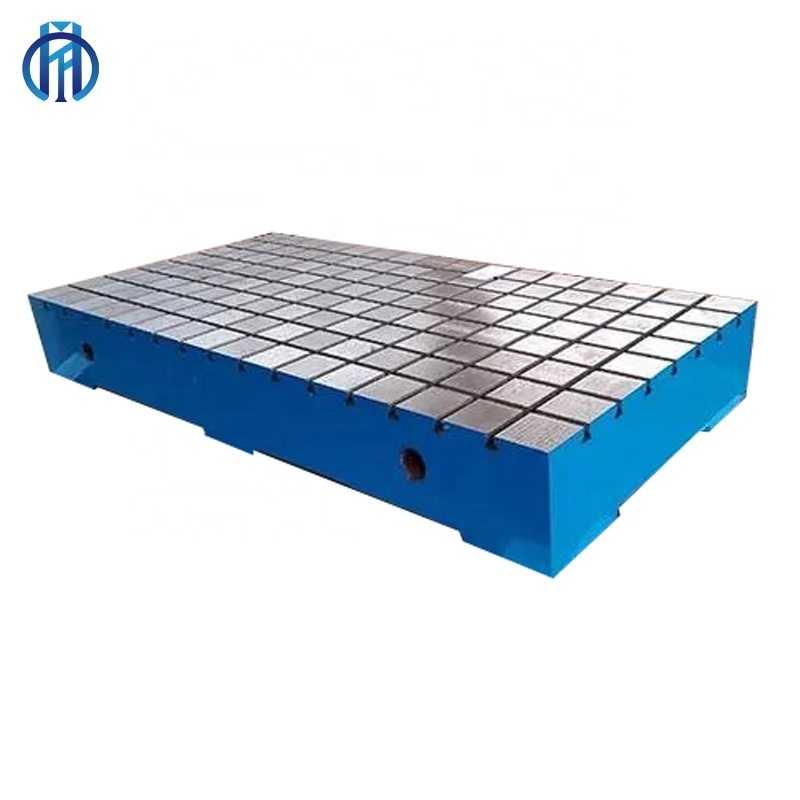

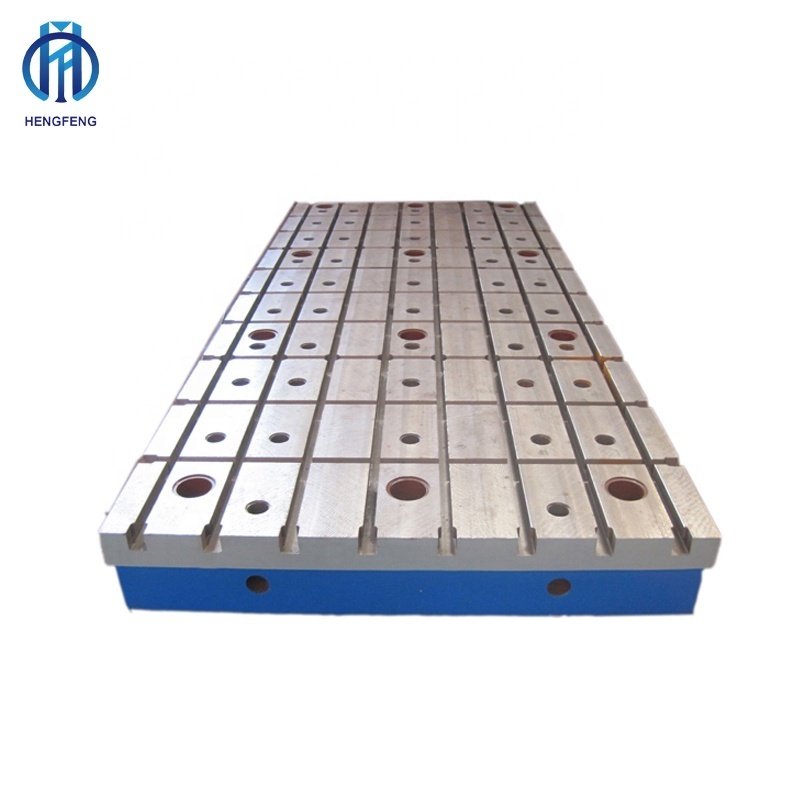

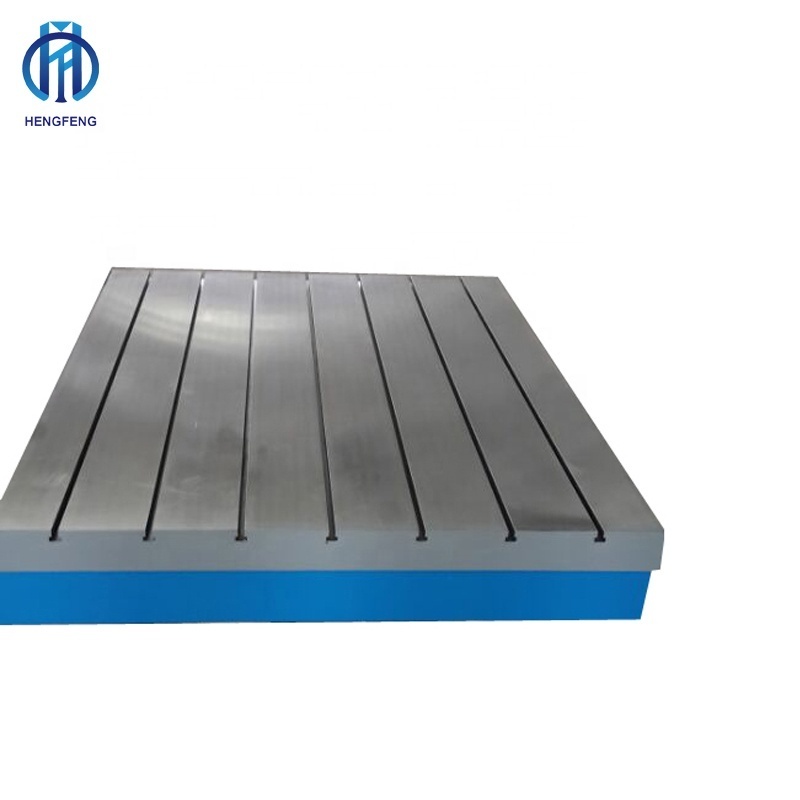

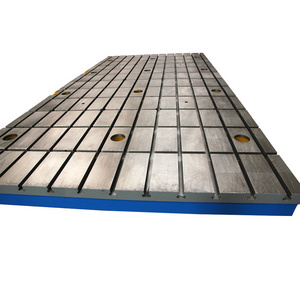

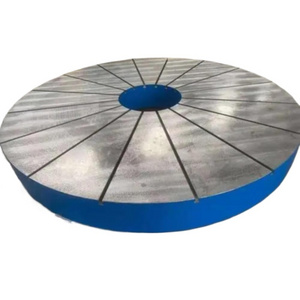

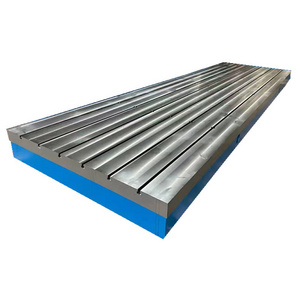

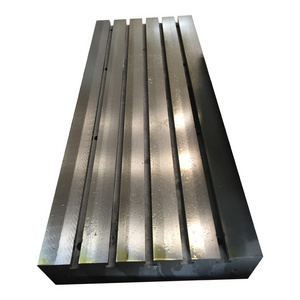

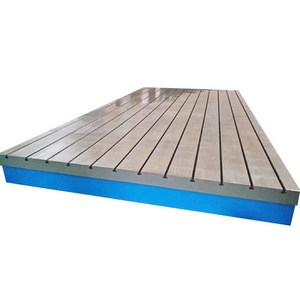

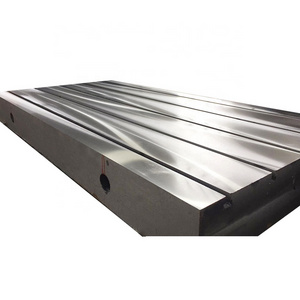

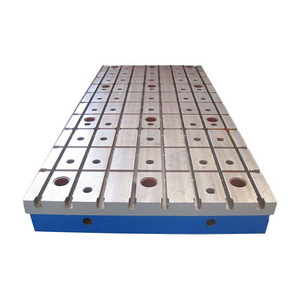

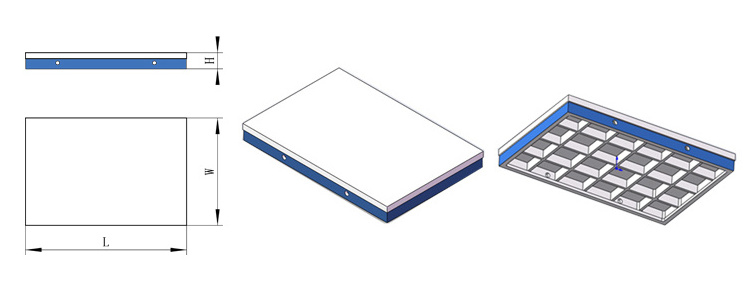

Cast Iron Surface Plate:

Cast iron surface plates are made up of Cast Iron (C.I), they are duly provided heat treatment for relieving internal stresses. They provide a precision reference for spotting, tool marking, inspection of workpieces, checking accuracy of other surfaces, for many types of gauging and marking out (layout) operation.

Heavy Duty Steel Stand:

Heavy Duty Steel Stand are usually custom designed to maintain the precision tolerances. Leveling screws and heavy-duty casters are available on the stands. Orders should specify the exact working height: from floor to the top of the surface plate.

Technical Specification of

Cast Iron Surface Plate:

Material: HT200-300

Specification: 200x200-4000x8000mm or customize

Working Surface: flat, grid slots for location, tapped holes, T-slots

Hardness of the working surface: HB160-240

Surface treatment: precisely finished by planning and hand scraping

Foundry process: resin sand casting

Structure: rib (bone) structure with enough wall thickness

Painting: primer and face paint

Surface coating: working surface covered with pickling oil and non-working surface covered with antirust paint

Heat-treated: available, for stress relief

Stands: available for corresponding sizes

Precision grade: 0-3

Working temperature: (20±5) ℃

Packaging: plywood box

|

No.

|

Width X Length(mm)

|

Precision Grade

|

|

|

|

|||

|

|

|

0

|

1

|

2

|

3

|

|||

|

|

|

Flatness

(μm)

|

|

|

|

|||

|

1

|

200X200

|

3.5

|

7

|

14

|

|

|||

|

2

|

300X200

|

4

|

8

|

15

|

|

|||

|

3

|

300X300

|

4

|

8

|

15

|

|

|||

|

4

|

300X400

|

4

|

8

|

16

|

|

|||

|

5

|

400X400

|

4.5

|

8.5

|

17

|

|

|||

|

6

|

400X500

|

4.5

|

9

|

18

|

|

|||

|

7

|

400X600

|

5

|

10

|

19

|

|

|||

|

8

|

500X500

|

5

|

10

|

19

|

|

|||

|

9

|

500X600

|

5

|

10

|

19

|

|

|||

|

10

|

500X800

|

5.5

|

11

|

21

|

|

|||

|

11

|

600X800

|

5.5

|

11

|

22

|

|

|||

|

12

|

600X900

|

6

|

11.5

|

23

|

|

|||

|

13

|

1000X750

|

|

12.5

|

25

|

50

|

|||

|

14

|

1000X1000

|

|

13.5

|

27

|

54

|

|||

|

15

|

1000X1200

|

|

14

|

29

|

58

|

|||

|

16

|

1000X1500

|

|

16

|

32

|

63

|

|||

|

17

|

1000X2000

|

|

18.5

|

37

|

74

|

|||

|

18

|

1500X2000

|

|

20

|

40

|

80

|

|||

|

19

|

1500X2500

|

|

22.5

|

45

|

90

|

|||

|

20

|

1500X3000

|

|

25

|

50

|

100

|

|||

|

21

|

2000X2000

|

|

22

|

44

|

88

|

|||

|

22

|

2000X3000

|

|

27

|

53

|

106

|

|||

|

23

|

2000X4000

|

|

32

|

64

|

127

|

|||

|

24

|

2000X5000

|

|

37

|

75

|

150

|

|||

|

25

|

2000X6000

|

|

43

|

86

|

172

|

|||

|

26

|

2000X7000

|

|

49

|

97

|

194

|

|||

|

27

|

2000X8000

|

|

54.5

|

109

|

218

|

|||

|

28

|

2500X3000

|

|

28.5

|

57

|

114

|

|||

|

29

|

2500X4000

|

|

33

|

67

|

133

|

|||

|

30

|

2500X5000

|

|

39

|

77

|

154

|

|||

|

31

|

2500X6000

|

|

|

88

|

176

|

|||

|

32

|

2500X7000

|

|

|

99

|

198

|

|||

|

33

|

2500X8000

|

|

|

110

|

221

|

|||

|

34

|

3000X3000

|

|

|

61

|

122

|

|||

|

35

|

3000X4000

|

|

|

70

|

140

|

|||

|

36

|

3000X5000

|

|

|

80

|

160

|

|||

|

37

|

3000X6000

|

|

|

90.5

|

181

|

|||

|

38

|

3000X7000

|

|

|

101

|

203

|

|||

|

39

|

3000X8000

|

|

|

112.5

|

225

|

|||

|

40

|

4000X4000

|

|

|

78

|

156

|

|||

|

41

|

4000X5000

|

|

|

87

|

174

|

|||

|

42

|

4000X6000

|

|

|

96.5

|

193

|

|||

|

43

|

4000X7000

|

|

|

107

|

213.5

|

|||

|

44

|

4000X8000

|

|

|

117

|

235

|

|||

Features of Cast Iron Surface Plate:

* Manufactured from high quality cast iron.

* Top surface is thick & solid.

* Heat-treated for stress relief, stability and wear resistance.

* Stands are available for corresponding sizes.

* Custom sizes are welcome as per request.

* Top surface is thick & solid.

* Heat-treated for stress relief, stability and wear resistance.

* Stands are available for corresponding sizes.

* Custom sizes are welcome as per request.

Precautions while using the Surface Plates:

* The flatness accuracy of the surface plate must be checked regularly to make sure the surface is in an ideal condition.

* The working surface must be properly cleaned before use in order to avoid dust and other polluted particles.

* Make sure to use every nook and corner of the plate so that the plate can be used in a uniform manner.

* The working surface should always be coated with corrosion resistive elements such as Oil or Grease after use.

* The working surface must be properly cleaned before use in order to avoid dust and other polluted particles.

* Make sure to use every nook and corner of the plate so that the plate can be used in a uniform manner.

* The working surface should always be coated with corrosion resistive elements such as Oil or Grease after use.

1. Customer First

Customer driven approach to meet any tailor-made requirements & deadlines.

2. Reliable Quality

Complete Design & Manufacturing facilities in house.

3. Timely Delivery

Factory supplier; arrange production accordingly and well control the production schedule.

4.Precision Solution

To provide high quality surface plates & measuring tools, services and solutions to all industries.

Hot Searches