When will you need the glycol system?

1. Wort production:

Going through the plate heat exchanger could be one of your glycol loops or a line from a cold liquor tank that is chilled via your glycol chiller.

2. Fermentation:

During this step, yeast will begin to consume sugars and release heat as a result.

Like an anxious driver flooring the gas pedal, this can lead to overheating during the process.

Carry glycol system will help put on the brakes, letting you have better control of internal temperatures and fermentation as a whole, and giving you more quality control over your beer.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

depends

-

Dimension(L*W*H):

-

depends

-

Weight:

-

500 KG, Various from configurations

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Industrial Cooling Unit

-

Material:

-

Internatinal Standard SUS304-SUS316L or Solid Copper

-

Inner polishing precision:

-

Roughness: Ra<0.6micrometer

-

Plate surface:

-

Mirror, wire drawing, 2B

-

Training:

-

Beginners to be trained

-

Certificate:

-

CE/ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CARRY, Carry

-

Voltage:

-

380v/450v/ depends, 380V/3PH/50Hz or according

-

Power:

-

depends

-

Dimension(L*W*H):

-

depends

-

Weight:

-

500 KG, Various from configurations

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Industrial Cooling Unit

-

Material:

-

Internatinal Standard SUS304-SUS316L or Solid Copper

-

Inner polishing precision:

-

Roughness: Ra<0.6micrometer

-

Plate surface:

-

Mirror, wire drawing, 2B

-

Training:

-

Beginners to be trained

-

Certificate:

-

CE/ISO

We provide complete beer brewing solutions that include:

malt milling system, mashing system, beer fermenting/storage system, cooling system, cleaning system, control system and so on.

It is made from fully polished 304 stainless steel, has all entry level sanitary welded tri-clamp fittings and CIP arm. There are some more advanced add-on features, it will be able to support your brewing needs as you expected.

Production Details

Cooling System

The cooling system is mainly cimposed of chiller, glycol water tank and glycol water pump.It is mainly used to maintain the temperature of fermentation tank and brite tank. And provide glycol water for it when the plate heating exchanger works

|

Description

|

|

Details

|

|

|

Cooling System

|

1500L Glycol Water Tank

|

1. Effective volume = 800L;Total volume =1000L.

2. Top-mounted manhole

3. Temperature Probe & PT - 100

4. Inner - Jacket (SUS304), TH=3.0MM, pickling & passivating treated

5. Inner - Jacket (SUS304), TH=2.0MM, ink wires drawing plate

6. PU Insulation layer = 80mm

7. with level tube

8. with glycol water inlet & outlet connection ports

9. with bottom drain port

|

|

|

|

Glycol

Water Pump

|

Flow = 3m3/h, Lift = 24m, 0.75km

|

|

|

|

Industrial Chiller

|

1. Cooling Capacity = 3HP

2. CANSA brand

3. Copland vortex compressor, more durable, refrigeration effect is more stable 4. Medium: Environmental protection refrigerants R407c

|

|

OTHER SYSTEM

|

Beer Brewery System

|

|

|

|

1

|

Milling System

|

|

|

2

|

Brewing System

|

|

|

3

|

Fermenting System

|

|

|

4

|

Cooling System

|

|

|

5

|

Cleaning System

|

|

|

6

|

Filling System

|

|

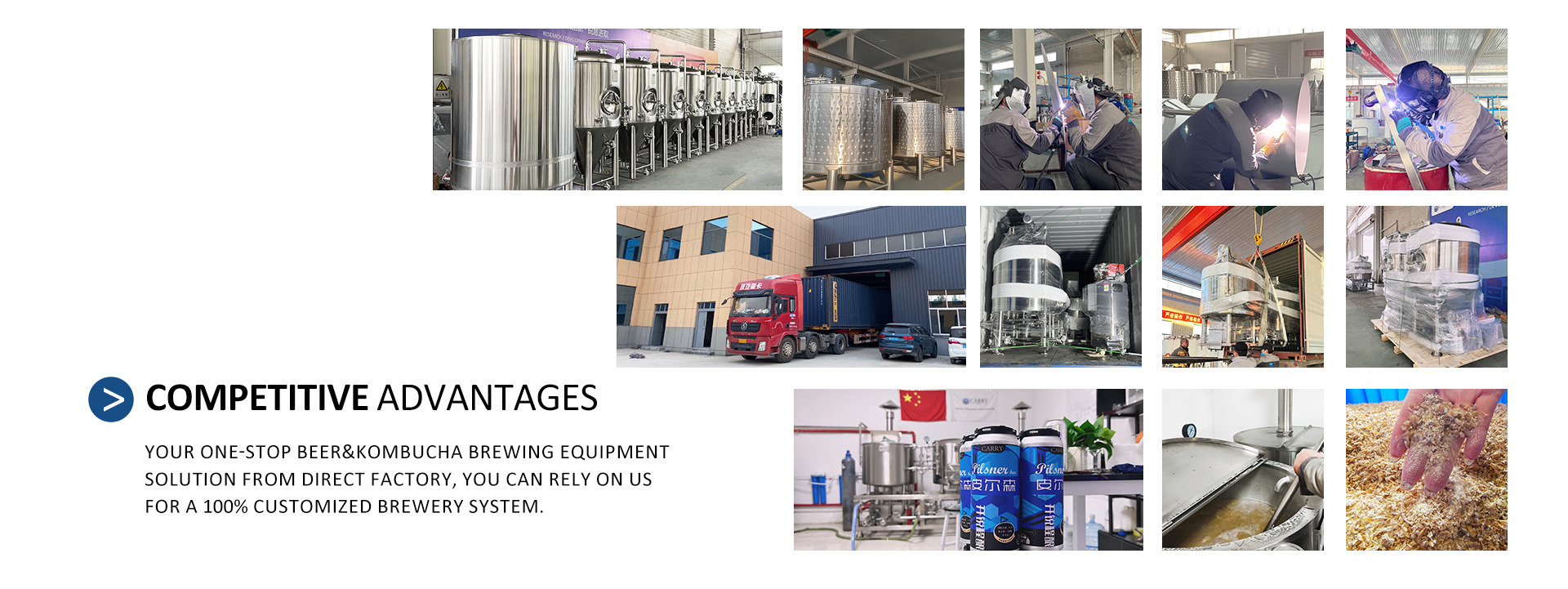

PACKING & DELIVERY

Inner stretching membrane and PE paper and outer steel frame, and another packaging for shipping.

1. Main beer brewing tanks, fermenting vessels, and turnkey brewhouse system will be packaged with plastic film firstly, then with reinforced steel frames.

2. All beer brewing spare parts, accessories, and fittings will be packaged in a carton box and crated.

3. All items are wrapped in a soft package for protection.

4. Each part of the whole brewing system will be labeled.

CERTIFICATIONS

COMPANY INFORMATION

Carry Equipment is a professional brewing equipment supplier in China. We have own factory and technology team. The staff has more than 10 years brewing experience and manufacturing experience.With the concept of " pioneering and enterprising", CARRY strives to consistently deliver high-quality products and the best service for our customer. Fully committed to the brewing industry, we always take customer’s requirement and satisfaction as our aim.

We specialized in manufacturing

beer brewing house, fermentation tanks, Cooling machines, CIP cleaning equipment,and other related beer machines. All of our machines can be customized as per your requirement.

CUSTOMER FEEDBACK

Hot Searches