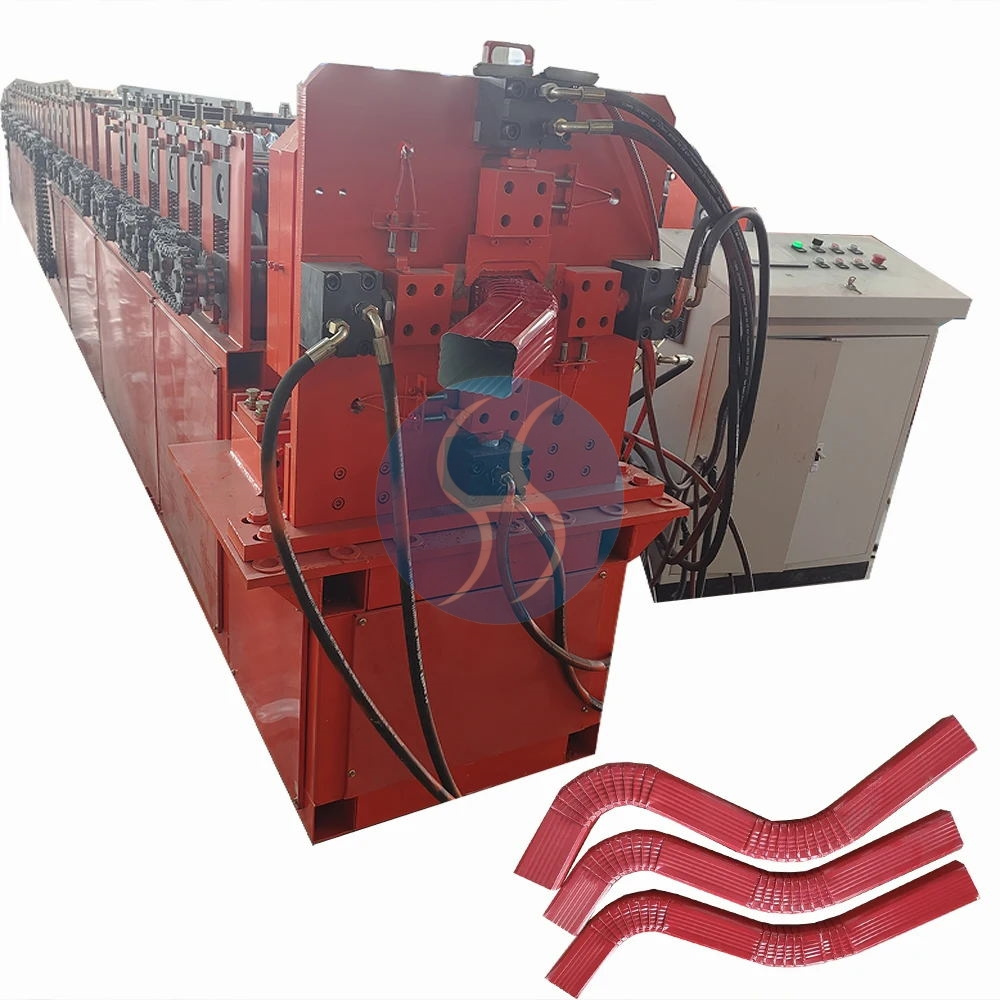

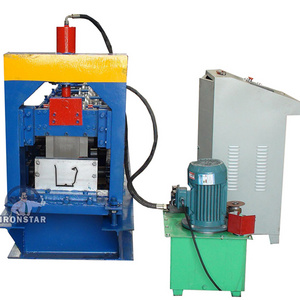

Roll Forming Making Machine adopts welded steel frame structure, it make sure roof sheet machine can operation more stable

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and

chrome coating.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

China

-

Brand Name:

-

HosonCNC

-

Voltage:

-

380V / 220V or as required

-

Dimension(L*W*H):

-

6800*800*1500mm

-

Weight:

-

4000 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Automatic Bending Downspout Forming Machine

-

Raw material:

-

Galvanized Coil

-

Application:

-

Building Construction

-

Main frame:

-

350mm/400mm H-Beam

-

Cutting blade material:

-

Cr 12 Mov

-

Roller material:

-

45#steel Chrome Plated

-

Roller stations:

-

18 Stations

-

Control system:

-

PLC

-

Shaft material:

-

High Grade No.45 Forged

-

Decoiler:

-

Manual Decoiler

Quick Details

-

Type:

-

Downspout Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

China

-

Brand Name:

-

HosonCNC

-

Voltage:

-

380V / 220V or as required

-

Dimension(L*W*H):

-

6800*800*1500mm

-

Weight:

-

4000 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Automatic Bending Downspout Forming Machine

-

Raw material:

-

Galvanized Coil

-

Application:

-

Building Construction

-

Main frame:

-

350mm/400mm H-Beam

-

Cutting blade material:

-

Cr 12 Mov

-

Roller material:

-

45#steel Chrome Plated

-

Roller stations:

-

18 Stations

-

Control system:

-

PLC

-

Shaft material:

-

High Grade No.45 Forged

-

Decoiler:

-

Manual Decoiler

Product Description

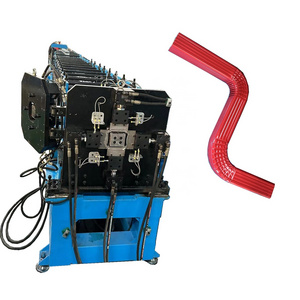

Roof Gutter Downspout Elbow Machine Rain Steel Downspout Roll Forming Machine with Elbow

Main features of downspout pipe roll forming machine

The advantages of downspout tube roll forming machine are as follows:

1.Make both downspout pipe and elbows(with bending device for engineering conveniece)

2.with square type downspout pipe and round type downspout pipe for option)

3.Easy operation, low maintenance cost

4.stable and efficient

Downspout Forming & Elbow Machine For Gutter

Specification

|

NO.

|

Item

|

Value

|

|

1

|

Raw material width

|

300-600 mm

|

|

2

|

Sheet effective width

|

80-200 mm

|

|

3

|

Raw material

|

Color steel sheet , Stainless steel or galvanized steel sheet

|

|

4

|

Material thickness

|

0.3-1 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

60 mm

|

|

7

|

Forming roll station

|

20-22 steps

|

|

8

|

Main motor power

|

3 KW 4 KW 5.5 KW(according to type)

|

|

9

|

Hydraulic power

|

4 KW (according to type)

|

|

10

|

Control system

|

PLC control

|

Details Images

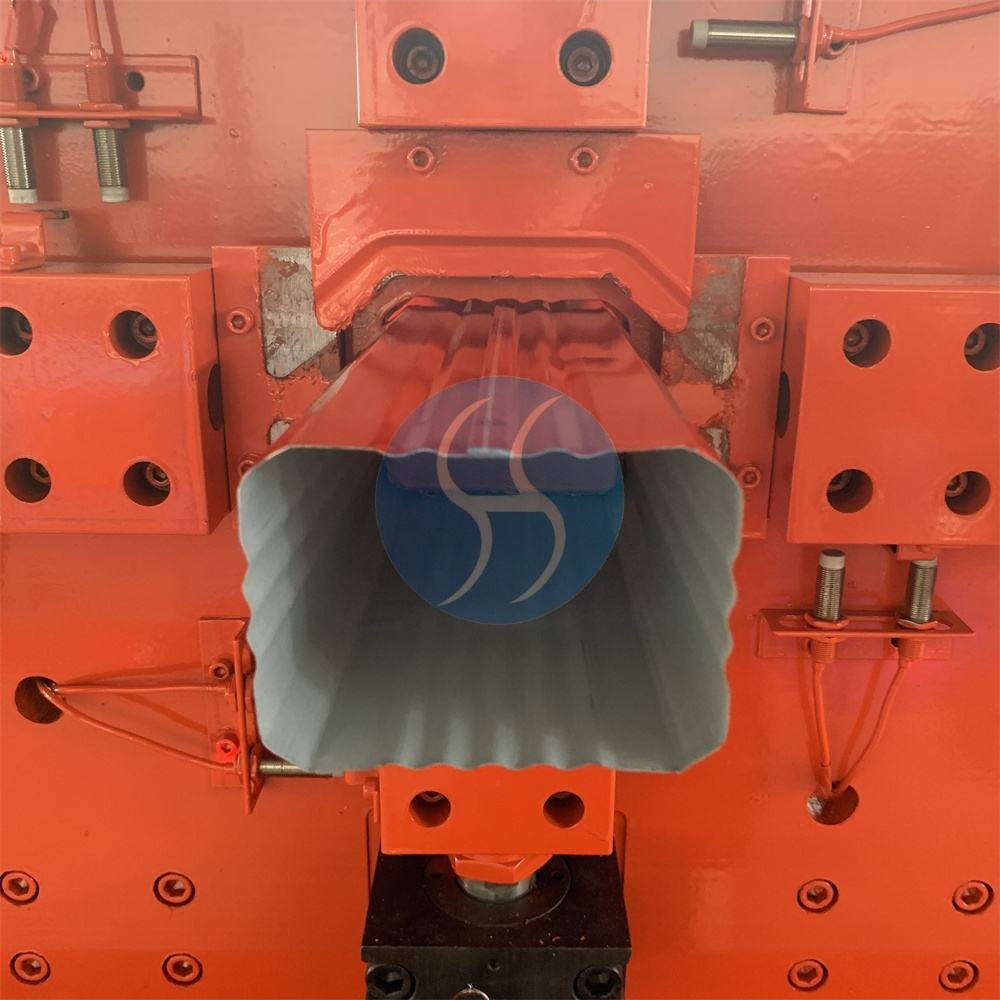

Machine frame of Rain Gutter Roll Forming Machine

Cutting Blade of Rain Gutter Roll Forming Machine

Roll Forming Making Machine blade using more high precious machine making, which can make sure the tile keep good shape, more

better for using.

The forming cutter of cold roll forming machine can cut raw materials of different materials.Our scissors can usually cut 0.3-0.6

mm steel plates.

better for using.

The forming cutter of cold roll forming machine can cut raw materials of different materials.Our scissors can usually cut 0.3-0.6

mm steel plates.

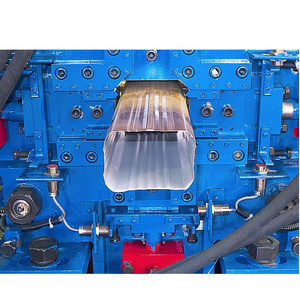

Forming Roller of Rain Gutter Roll Forming Machine

Roof sheet make machine forming roll quality will decide roof sheet shapes, we can according to your local roof shape customized

different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

PLC control part of Rain Gutter Roll Forming Machine

Roll Forming Making Machine control parts have different types, standard type are button control, through press buttons to

realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

Hot Searches