- Product Details

- {{item.text}}

Quick Details

-

Width of bed (mm):

-

25 mm

-

Spindle Motor Power(kW):

-

3.7

-

Travel (X Axis)(mm):

-

40 mm

-

Travel (Z Axis)(mm):

-

180 mm

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

1920*1540*1800

-

Brand Name:

-

JIANKE

-

Voltage:

-

380V

-

Weight (KG):

-

1800

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

Products name:

-

3 axis cnc precision lathe machines types price in india

-

Max machining diameter:

-

20mm

-

Operating system:

-

TAIWAN SYNTEC

-

Max rotary speed:

-

8000rpm

-

Minimum set unit:

-

0.001mm

-

Axis number:

-

3 axis ,X/Y/Z

-

Key word:

-

cnc lathe

-

Spindle type:

-

Single spindle , electric oil cooling

Quick Details

-

Type:

-

TURNING CENTER

-

Max. Length of Workpiece (mm):

-

200

-

Max. Spindle Speed (r.p.m):

-

8000 r.p.m

-

Width of bed (mm):

-

25 mm

-

Spindle Motor Power(kW):

-

3.7

-

Travel (X Axis)(mm):

-

40 mm

-

Travel (Z Axis)(mm):

-

180 mm

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

1920*1540*1800

-

Brand Name:

-

JIANKE

-

Voltage:

-

380V

-

Weight (KG):

-

1800

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

Products name:

-

3 axis cnc precision lathe machines types price in india

-

Max machining diameter:

-

20mm

-

Operating system:

-

TAIWAN SYNTEC

-

Max rotary speed:

-

8000rpm

-

Minimum set unit:

-

0.001mm

-

Axis number:

-

3 axis ,X/Y/Z

-

Key word:

-

cnc lathe

-

Spindle type:

-

Single spindle , electric oil cooling

Products Description

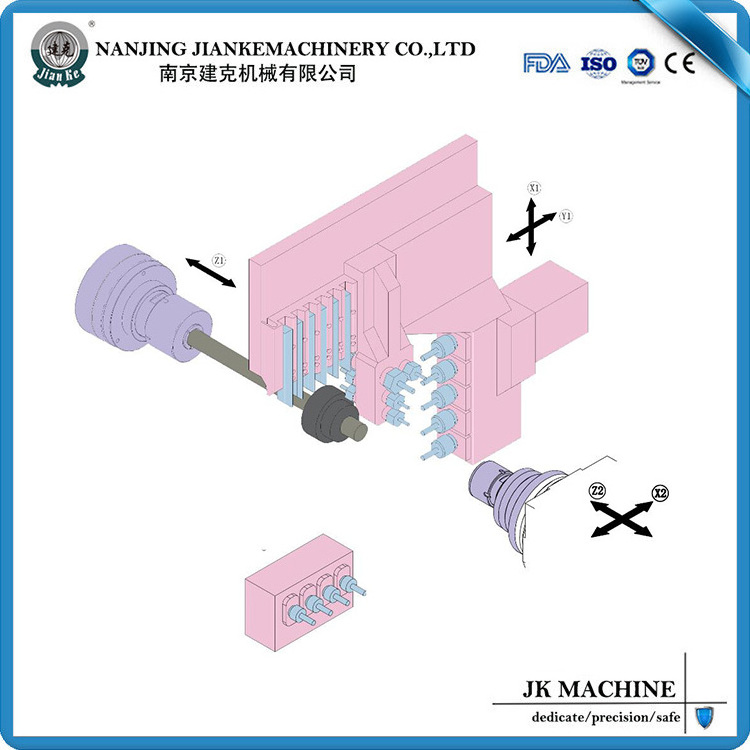

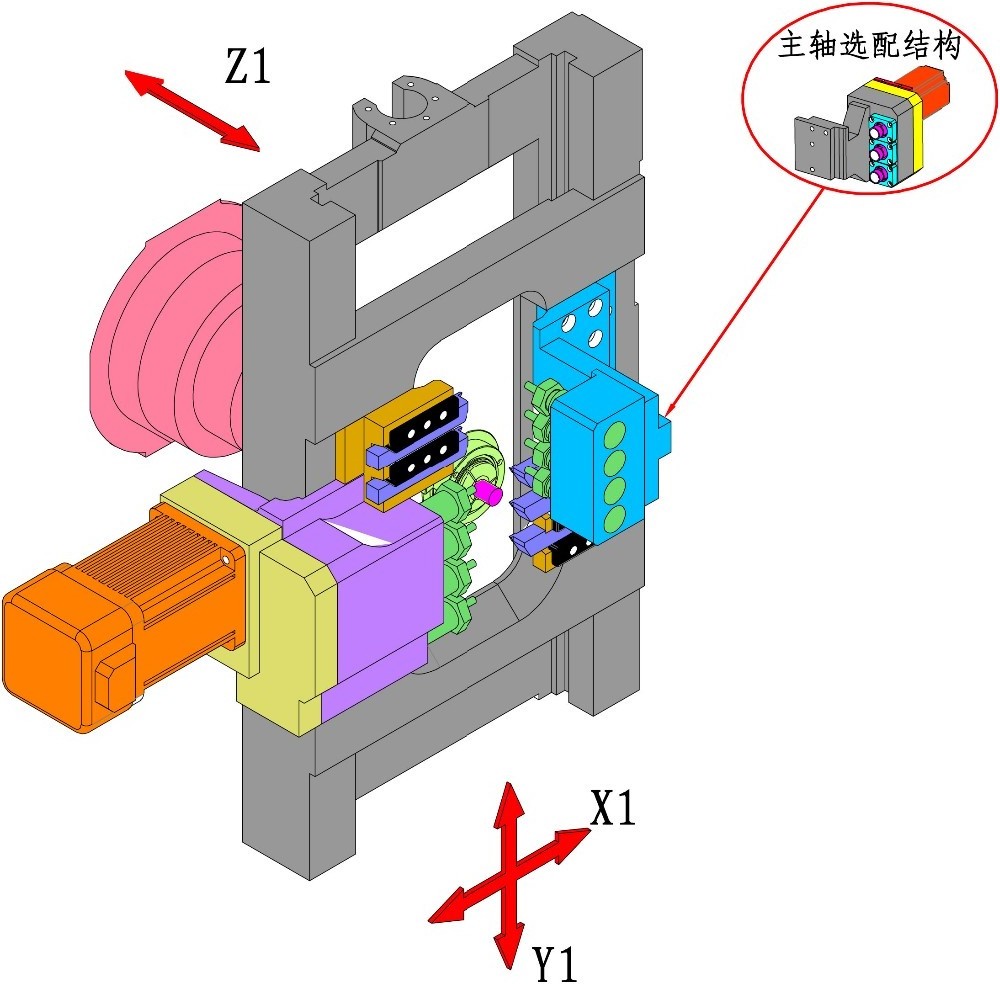

Lathe Appearance/Tool Holder Structure

Swiss type CNC lathe single spindle 5 axis model ZR20-3 Ⅱ

●

excellent performance

●

ability powerful

●

Operate flexbile

Main spindle

●

Adopt imported NSK bearing、THK guide rail, High precision, Long life.

●

Oil cooling electric spindle, comprehensive cooling during high speed, Flexible tool arrangement design, option freely.

●

Absolute type operation, machine working when start, no need to back to home position every time, save time.

Details Images

1.

Description

Brief Introduction

:ZR series are Swiss high-speed precision Swiss CNC lathes, which have the ability of turning and milling. They are high-precision, wide-range and practical processing equipment. This type of machine tool is suitable for "slender shaft" parts with a relatively large length and diameter. High-volume, multi-variety, and high-precision machining tasks of "small" and "abnormal" parts. Widely used in various high-precision, multi-batch, complex-shaped shaft parts in medical, aviation, aerospace, military, automobiles, motorcycles, communications, refrigeration, optics, home appliances, microelectronics, electronics, watches, mobile phones and other industries And complex machining of precision and small parts.

Functions

: ZR20-3Ⅱ Swiss CNC lathe could load Ф3mm -Ф20mm bar material; equipped with 5 external turning tools, 4 end face machining tools, 4 side power tool heads, which can be clamped at one time: turning external circle, cone, arc , Curved surface, internal and external threads, milling grooves, cutting slot, spiral groove, end face side drilling, boring, end face side tapping, lettering and other compound processing procedures, which can reduce the number of clamping times and shorten the product manufacturing process chain , Improve processing accuracy and production efficiency.

2.Standard Accessories

|

No.

|

Name

|

Qty

|

Note

|

|

1

|

Protective cover

|

1

|

|

|

2

|

Signage

|

1

|

Various warning signs, machine

|

|

3

|

Main spindle

|

2

|

Oil cooling electric spindle(Main and Sub spindle)

|

|

4

|

Turning tool row seat

|

2

|

Double tool holders on both sides(2+3 arrangement)

|

|

5

|

Side power tool holder

|

1

|

|

|

6

|

Main spindle end face drilling seat

|

1

|

|

|

7

|

Sub spindle end face drilling seat

|

1

|

Support plug-in module

|

|

8

|

Live rotary guide bush

|

1

|

|

|

9

|

Pneumatic system

|

1

|

Taiwan AIRTAG

|

|

10

|

cooling system

|

1

|

YUNHAI pump

|

|

11

|

Lubrication system

|

1

|

Japan HERG

|

|

12

|

Electrical System

|

1

|

Schneider

|

|

13

|

Material receive device

|

1

|

Material receive device /Long material aid device

|

|

14

|

Lathe lighting

|

1

|

DC24V

|

|

15

|

Three-color warning light

|

1

|

|

|

16

|

Special tool box

|

1

|

Special tools included

|

3.Options equipments(if needed , please list them in the contract/quotation)

|

NO

|

Name

|

Functions

|

Note

|

|||

|

1

|

Bar feeder

|

Realize automatic feeding/refueling function for long bar materials;

Assisting the Swiss CNC lathe to achieve automated production;

|

Recommended essential

|

|||

|

2

|

High pressure pump

|

Assist in targeting materials that are prone to chip breakage, chip removal, and erosion, reducing the probability of tool chip

entanglement;

Extend tool life;

Improve the accuracy/smoothness of some machining steps;

|

Select according to demand

|

|||

|

3

|

Oil mist collector

|

Absorb the atomized oil mist inside the equipment, reduce the overflow of oil mist from the equipment, and maintain the workshop

environment。

The models are divided into electrostatic type and filter type。

|

Select according to demand

If equipped with a high pressure pump

Recommended mandatory oil mist collector

|

|||

|

4

|

Chip conveyor

|

Chain type conveyor remove chips fro lathe collector, standard equipped with a chip trolley. Reduce the frequency and workload of

manual chip removal.

|

Select according to demand

|

|||

|

5

|

Plug type modules

|

End face rotary tools/Angle rotary tools/Thread whirling/Hobbing base/Saw blade base/Boring tool base…

|

Due to various modules/functions, Please confirm with JIANKE according to actual machining requirements.

|

|||

|

6

|

Long parts discharge from backwards

|

If the parts are longer that the collector opening, need change to eject it from backwards of sub spindle

|

Select according to demand

|

|||

|

…

|

…

|

……

|

…

|

|||

|

Due to the different options/configurations of the Swiss CNC lathe, the above are regular configurations. If you have special needs, please communicate and confirm with JIANKE.

|

|

|

|

|||

4.Main accessory brand

|

Name

|

Origin and Brand

|

|

Operation System

|

SYNTEC(Made in TAIWAN)

|

|

Spinlde and Driver

|

Oil cooling electric spindle/Mitsubishi driver

|

|

Bearing

|

Japan NSK

|

|

Guide rail

|

Japan THK/Taiwan Hiwin/Taiwan PMI

|

|

Guide screw

|

Japan THK/Taiwan Hiwin/Taiwan PMI

|

|

Servo Motor

|

SYNTEC(Made in TAIWAN)

|

|

Motor driver

|

SYNTEC(Made in TAIWAN)

|

|

Electrical components

|

France Schneider

|

|

Lubricant system

|

Japan Herg

|

|

Relay

|

Japan Omron

|

|

Stroke switch

|

Japan Omron

|

|

Magnetic valve

|

Taiwan Airtag

|

5.Swiss CNC lathe requirements for raw materials in the processing of long bar materials.

6. Quality assurance and technical support

The warranty period for the supplier's equipment is one year from the date of final acceptance by the Buyer before shipment. Under normal use, there is a free service warranty for damage. If the equipment is damaged due to improper use by the buyer, the supplier will only charge material fees within one year, and material and labor fees will be charged after one year. The supplier shall provide paid services /spare parts to the buyer for a long time. Make the following commitments to technical support, pre-sales, in sales, and after-sales service and quality

Product Paramenters

|

Double spindle Swiss CNC lathe ZR20-3II

|

|

|

|

|||

|

|

|

|

|

|||

|

System

|

Taiwan SYNTEC

|

Syntec21TB-E

|

|

|||

|

|

Control channel

|

Single channel

|

|

|||

|

|

Minimum setting unit

|

0.001mm

|

|

|||

|

Machining

|

Max processing Dia

|

20 mm

|

|

|||

|

|

Max processing length at one time

|

With guide bush

|

90mm

|

|||

|

|

|

Without guide bush

|

1:2.5D(Dia:Lenth)

|

|||

|

|

Main spindle max drilling Dia

|

Main spindle axial

|

Φ10mm

|

|||

|

|

Main spindle max tapping Dia

|

Main spindle axial

|

M8

|

|||

|

|

Power head max drilling Dia

|

Radial

|

Φ8mm

|

|||

|

|

Power head max tapping Dia

|

Radial

|

M6

|

|||

|

Tool

|

Tool seat arrangement

|

Double tool holders from both sides

|

|

|||

|

|

Main spindle turning tool

|

5 pieces

|

12X12mm

|

|||

|

|

Main spindle side roatry power head

|

4 pieces

|

2 Pieces ER11+2 PiecesER16

|

|||

|

|

Main spindle end face fixed tool seat

|

4 pieces

|

ER11/ER16

|

|||

|

Main

Spindle

|

Main spindle type

|

Built-in oil-cooled electric spindle

|

|

|||

|

|

Main spindle speed

|

10000rpm/min

|

|

|||

|

|

Main spindle index

|

0.001°

|

|

|||

|

|

Main spindle hole Dia

|

22mm

|

|

|||

|

|

Main spindle center height

|

990mm

|

|

|||

|

Motor Power

|

Main Spindle power (rated/maximum)

|

2.2kw/3.5kw

|

|

|||

|

|

Side rotary head motor power

|

0.75kw

|

|

|||

|

|

Side rotary head speed

|

6000rpm/min

|

|

|||

|

|

No. of moving axis

|

3 axis

|

X、Y、Z

|

|||

|

|

Rapid feeding speed

|

X、Y

|

24m/min

|

|||

|

|

Z

|

28m/min

|

|

|||

|

|

Moving axis motor power

|

0.75kw

|

|

|||

|

Other

|

Parts receive device

|

Short bar

|

Parts conveyor collect parts

|

|||

|

|

|

Long bar

|

Sub spindle backside collect parts

|

|||

|

|

Power capacity

|

10.5kw

|

|

|||

|

|

Air pressure

|

Above 0.4MPa

|

|

|||

|

|

Cutting oil tank capacity

|

175L

|

|

|||

|

|

Machine size(L*W*H)

|

1.65mx1.4mx1.7m

|

|

|||

|

|

Lathe Weight

|

1785KG

|

|

|||

Certifications

Hot Searches