- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JIAMEI

-

Voltage:

-

220/380/440

-

Power:

-

7.5kw

-

Weight:

-

380 KG

-

yarn size:

-

100-500d, 500-1500d

-

Tenacity:

-

high to 7g/d , white yarn

-

Output:

-

high efficiency, 1.2-1.5 tons base on 300D

-

control:

-

plc with touch screen

-

Other name:

-

auto doffing winder

-

Name:

-

carpet spinning winder

-

Keywords:

-

automatic yarn take up winder

-

Material:

-

BCF yarn winder

Quick Details

-

Application:

-

yarn winding machine, belt/ filter/ sewing twine/ rope etc

-

Production Capacity:

-

2000-3000m/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JIAMEI

-

Voltage:

-

220/380/440

-

Power:

-

7.5kw

-

Weight:

-

380 KG

-

yarn size:

-

100-500d, 500-1500d

-

Tenacity:

-

high to 7g/d , white yarn

-

Output:

-

high efficiency, 1.2-1.5 tons base on 300D

-

control:

-

plc with touch screen

-

Other name:

-

auto doffing winder

-

Name:

-

carpet spinning winder

-

Keywords:

-

automatic yarn take up winder

-

Material:

-

BCF yarn winder

2 or 3 Heads Polyester PP BCF Yarn Winder/ automatic carpet spinning take up winder

Professional : we make only extruder machine

Experience : 20 years experience in extruder field

Machine type : PP, PE ,PA ,PET, NYLON monofilament/ multifilament

BCF WINDER

automatic doffing fdy poy winder

2 or 3 Heads Polyester PP BCF Yarn Winder/ automatic carpet spinning take up winder

1. automatic bobbin change

2. speed: 1800-2800m/min for pp

3. have chuck 600m, 920mm, 1200mm, and also can be customized to do

Feature & application

2 or 3 Heads Polyester PP BCF Yarn Winder/ automatic carpet spinning take up winder

1.pp multifilament spinning machine is used for spinning multi-types of polypropylene high-tenacity multifilament , which is for fully oriented yarn. This high performance PP Yarn can be adopted as raw material of webbing, fabric tape, sewing thread, filter cloth , rope, concrete fiber .

2.pp multifilament spinning machine is equipped with good quality screw extruder,automatic loading system ,spinning box ,metering pump,hot godets, automatic fdy winder

3.Maximum winder speed up to 2500m/min , highly productive, brilliant reliability, good invest return rate

4. Fully integrated spinning-control system , PLC

5.compact size, lower height and modularized platform , can fit in general workhouse.

6. Yarn Strength up to 7g/d

polypropylene multifilament

T he extruder plasticizes and homogenizes the polymer and feeds it into the electrically heated spinning head.

The precision gear pump force controlled the melt to the spinning packs with the spinnerets. In the quenching cabinet the filaments are quenched by air.

Subsequently they are bundled together, provided with spin-finish oil, drawn, intermingled and wound up to bobbins.

Technical process of FDY polypropylene spinning machine:

Chips→ extruder→ extruding head →melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ four pairs of hot godet→ inter lacing jets→ take-up winder →final product

machine model

|

Item |

JM261 |

JM241 |

JM811 |

JM161 |

JM141 |

JM131 |

JM121 |

|

Pos |

2 |

2 |

1 |

1 |

1 |

1 |

1 |

|

Fibre denier |

500-1500D( SINGLE YARN) |

||||||

|

Spinneret/pos |

6 |

4 |

8 |

6 |

4 |

3 |

2 |

|

Metering pump |

12cc |

||||||

|

Winder speed |

2000-2400m/min |

||||||

|

Capacity (900d) |

3.5toms |

2.3tons |

2.3tons |

1.7tons |

1.2tons |

0.8tons |

0.6tons |

|

Screw dia |

120mm |

105mm |

90mm |

90mm |

70mm |

70mm |

55mm |

|

Power |

280kw |

130kw |

120kw |

150kw |

120kw |

100kw |

90kw |

|

Machine size |

5.5*5*6.5m |

||||||

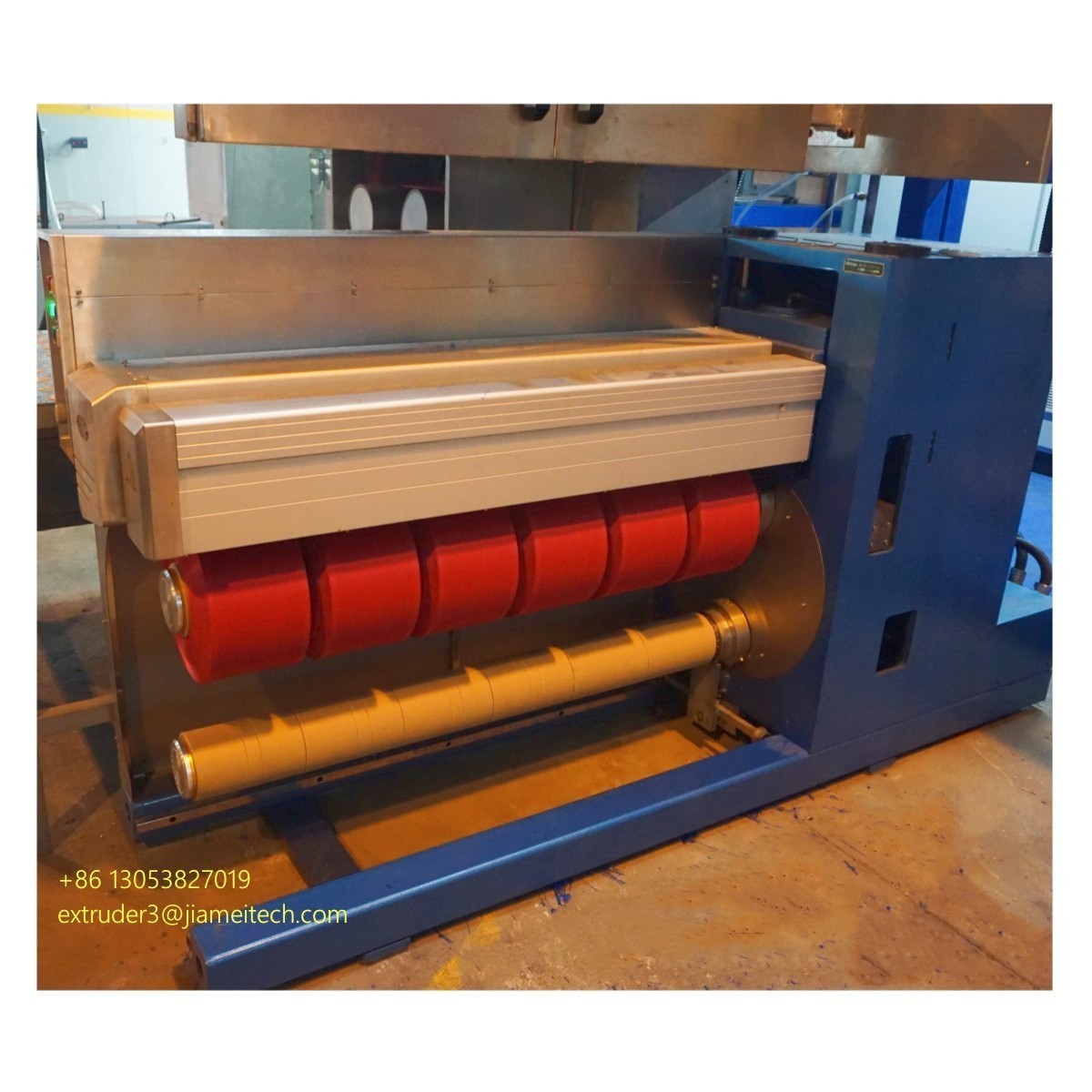

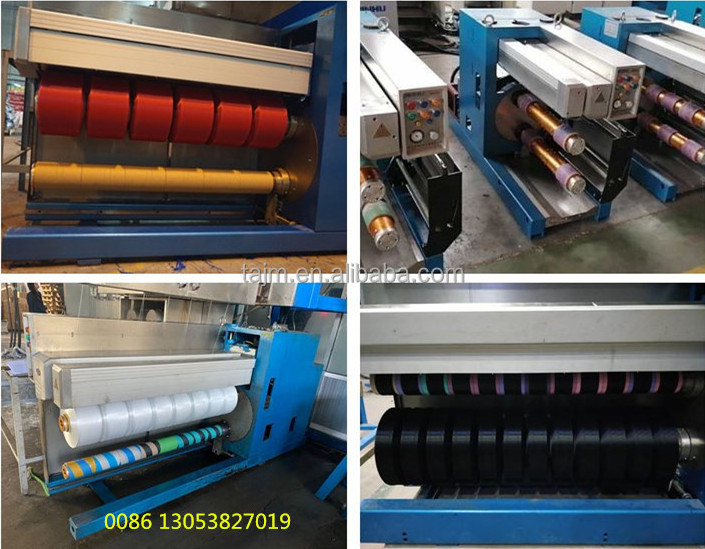

Machine photo :

Automatic bobbin winder

2 or 3 Heads Polyester PP BCF Yarn Winder/ automatic carpet spinning take up winder

1. automatic bobbin change

2. winder mechnical speed : max 3000m/min

operating speed: 1800-2800m/min

3. different bobbin size to meet request , 150mm, 200mm , 230mm, 172.5mm, 270mm, 300mm

4. top quality in china

5. plastic traverse type, PLC control

finished products, pp multifilament spinning machine

1. webbing and belt making

2. sewing thread

3. rope production

4. concrete and cement fibre

5. filter cloth

6. sofa, beach bed, beach chair, Beach hammock

After-sales service

2 or 3 Heads Polyester PP BCF Yarn Winder/ automatic carpet spinning take up winder

1.Come engineer for machine set up, it need 12-15 days

2. support with operating training

3. spare parts supply immediately

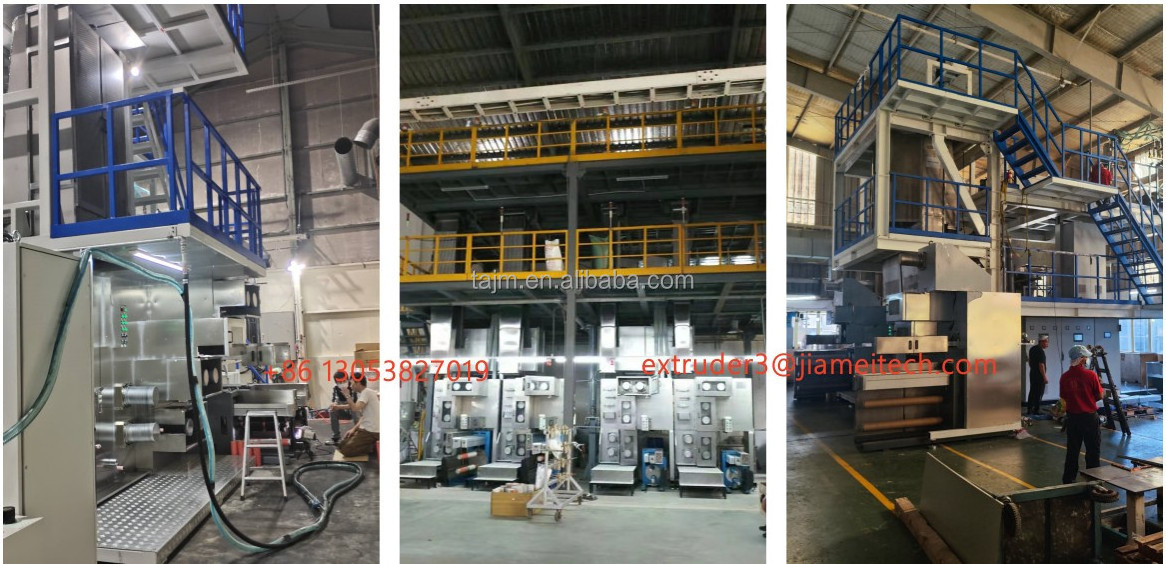

workshop

Tainan jiamei machinery technology co.,ltd ha ve good experience of 30 years in machinery manufacturing and development.

Our main products including fdy pp multifilament spinning machine, polyester multi yarn spinning machine, BCF carpet multifilament spinning machine. All kinds of plastic filament extruding machine. so far , many customers have gain very good economic benefits with our equipment.

1. Machine Manufacturing years: over 30 years

2. Workshop area: 10000square meters

3. Qty of workers: 80-100

4. We have yarn production with own machine over 15 years

related machine

this kind of mahcine is used for twisting sewing twine, filter cloth , fihsing net, webbing net yarn etc

2 or 3 Heads Polyester PP BCF Yarn Winder/ automatic carpet spinning take up winder