B. Thick steel surface rust removal C. PLC control , can achieve automatic operation

D.Deburring, deflashing and cosmetic finishing

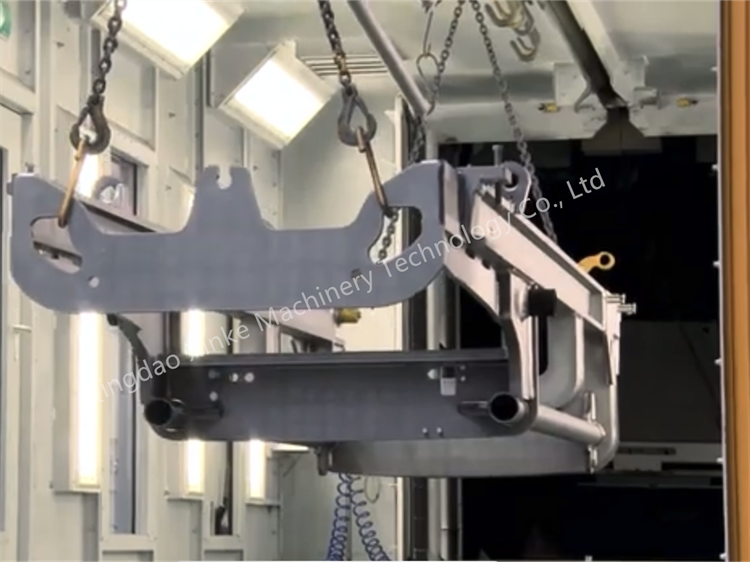

E. When production requires dictate batch processing

F. Small to medium size castings, fabrications and heat-treated parts G. Suitable for the unfavorable impact of long and thin, thin wall parts shot blasting machine, overhead rail shot blast machine, monorail sand blasting machine