In combination with various types of electric hammer, the drill is one of the most efficient tools suitably and widely use for hole drilling in hard materials like concrete/brick in construction & installation industries.

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

NONE

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUERONG

-

Model Number:

-

160MM

-

Working Length (mm):

-

18*160mm

-

Product name:

-

YUERONG 160MM Length Yueqing drill tools SDS Plus single flute flat ti

-

Body Material:

-

40Cr with heat treatment

-

Tip Material:

-

YG8C

-

Size:

-

3*110MM-65*6000MM

-

Tip Type:

-

Flat tip/Single tip,Cross tip,Three carbide tip

-

Flute Type:

-

Double flute,Single Flut

-

Service:

-

One-stop service

-

Testing Equipment:

-

Automatic testing machine

-

Sample:

-

Free sample

-

Qulity:

-

High qulity

Quick Details

-

Type:

-

SDS Plus hammer drill bit

-

Use:

-

Masonry Drilling

-

Finish:

-

Sandblasting

-

Warranty:

-

NONE

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUERONG

-

Model Number:

-

160MM

-

Working Length (mm):

-

18*160mm

-

Product name:

-

YUERONG 160MM Length Yueqing drill tools SDS Plus single flute flat ti

-

Body Material:

-

40Cr with heat treatment

-

Tip Material:

-

YG8C

-

Size:

-

3*110MM-65*6000MM

-

Tip Type:

-

Flat tip/Single tip,Cross tip,Three carbide tip

-

Flute Type:

-

Double flute,Single Flut

-

Service:

-

One-stop service

-

Testing Equipment:

-

Automatic testing machine

-

Sample:

-

Free sample

-

Qulity:

-

High qulity

Products Description

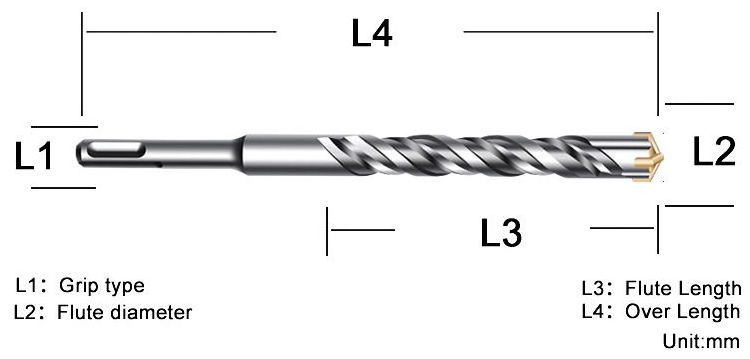

SDS Plus Drill Bits For Concrete Drilling

|

SIZE(MM)

|

L1(MM)

|

L2(MM)

|

L3(MM)

|

L4(MM)

|

|

4*160

|

10

|

4

|

110

|

160

|

|

5*160

|

10

|

5

|

110

|

160

|

|

5.5*160

|

10

|

5.5

|

110

|

160

|

|

6*160

|

10

|

6

|

110

|

160

|

|

6.5*160

|

10

|

6.5

|

110

|

160

|

|

7*160

|

10

|

7

|

110

|

160

|

|

8*160

|

10

|

8

|

110

|

160

|

|

9*160

|

10

|

9

|

110

|

160

|

|

10*160

|

10

|

10

|

110

|

160

|

|

12*160

|

10

|

12

|

110

|

160

|

|

14*160

|

10

|

14

|

110

|

160

|

|

16*160

|

10

|

16

|

110

|

160

|

|

18*160

|

10

|

18

|

110

|

160

|

|

|

||

|

Product Name

|

Carbide Flat/Single Head Tip U Flute SDS Plus Rotary Hammer Drill Bit for Concrete and Hard Stone

|

|

|

Body Material

|

40Cr Steel with Heat Treatment

|

|

|

Tip Material

|

Tungsten Carbide

|

|

|

Process

|

Milled Flutes and Welded Tip

|

|

|

Shank

|

SDS-Plus shank (SDS-Max shank, Hex shank, SDS Tapcon shank, Spline shank are avavilable )

|

|

|

Tip Type

|

Flat/Single (Centric tip,Single tip , X head are available)

|

|

|

Flute Type

|

U Flute ( S4 Flute and L Flute are available)

|

|

|

Size

|

3*110mm - 65*6000mm (5/32" * 4" to 2 3/5" * 240")

|

|

|

Surface Finish

|

Sand Blasted

|

|

|

Package

|

One Piece in One PVC Pouch Or Plastic Hanger or PVC Tube or PVC Double Blister

|

|

|

Features

|

1.Professional quality for efficient and fast hammer drilling in hard materials like concrete, granite, brick and other similar

building materials. |

|

|

|

2.Premium carbon steel with heat treatment improves core strength for maximum durability and extended life.

|

|

|

|

3.Hardened, premium carbide insert tip is strong and stays sharp longer for finer material break up and easier drilling increases

strength and durability. |

|

|

|

4.Copper braze material gives high heat resistance for reduced tip loss,Carbide tip securely embedded in the steel body.

|

|

|

|

5.U flute ensures fast, efficient removal of drilling dust and debris to increase speed and prevent clogging.

|

|

|

|

6.Wear mark identifies when bit has worn to an inappropriate level for precision anchoring.

|

|

|

|

7.Compatible with all SDS-PLUS style chucks.

|

|

Drill bits are cutting tools used to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck.

Drill bits come in standard sizes, described in the drill bit sizes article. A comprehensive drill bit and tap size chart lists metric and imperial sized drill bits alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section.

(from wikipedia)

Application

Why Choose Us

Why choose us? Clik&Contect us!!!

Advantages of electric hammer drill:

1. complete specifications: Diameter from 3mm-60mm, length from 110mm-6000mm, all can be produced.

2. Long product life: see the table "punching quantity standard for part products" and testing video.

3. Drilling speed: High Alloy sharpness, excellent chip removal, make sure the fast drilling speed. Spend about 12 seconds for a hole drilling, see the test video.

4. High Hardness Standard: The hardness of drills are 48-51 degrees in my company, higher than the general manufacturers of 45-48 degrees standard. At the same time, it takes into account the

toughness and is not easy to break.

5. Quality stability: incoming inspection, 5 steps of process acceptance and finished product broken

testing , to ensure the quality stability.

Raw material advantages:

1. Grade of raw materials: the alloy used by our company is the highest grade raw material, such as

diameter 12mm, just have 422 pcs per kilogram.

2. Alloy R & D: In 2019, my company has invested about RMB 200,000 in alloy research and development, and has our own alloy appearance patent. And enjoy the priority supply of all new

products developed by the alloy factory.

3. Incoming inspection: our company has established its own alloy acceptance standard. From March to August 2020, more than 20 batches of incoming materials have been inspected for only 6mm. All unqualified alloys will be returned.

Core equipment and technical advantages :

1. Equipment advantages: all processes are completed by ourselves from the beginning to the end, and do not rely on external processing.

2. High degree of automation: 90% of the equipment in my factory is fully automated, with automatic cold heading machine, automatic instrument, automatic groove milling , automatic cutting, automatic welding, automatic welding and other equipment. The full automation rate is in the leading position in China.

3. Core welding technology: after decades of repeated research on welding flux, welding time, welding temperature and welding quality, we have mastered the core welding datas. Ensure that there is no bias welding, no missing welding and no alloy dropping in case of high temperature.

4. Core quenching technology: the heat treatment time is about 3-4 hours. Through the automatic mesh belt quenching furnace, the temperature and the time of heat treatment are strictly controlled. Also we have secondary tempering process . what’s more, the strict product placement standard is added to realize the double guarantee of product hardness and toughness (see the picture of our company's product placement ).

5. Chip removal technology: repeatedly study and summarize the spiral width, depth, span and direction of starting and closing, we formulate different screw standards for different products, to achieve the optimal chip removal and not easy to break.

Other guarantee of our factory:

1. Delivery guarantee: for orders below 500,000pcs, the delivery time is generally controlled within 30-60 days. There is no delay in delivery.

2. Factory stability: the product line is simple, the target is clear, and the expansion is not blind. From the establishment to now, our factory are steadily rising.

3. Customer competitiveness: our company stipulates that the sales target of single market shall not be exceed RMB 10 million, so as to ensure that our customers can enjoy sufficient

competitiveness. https://furong.en.alibaba.com/contactinfo.html

4. Customized service: OEM and ODM are accepted in our factory.

Advantages of electric hammer drill:

1. complete specifications: Diameter from 3mm-60mm, length from 110mm-6000mm, all can be produced.

2. Long product life: see the table "punching quantity standard for part products" and testing video.

3. Drilling speed: High Alloy sharpness, excellent chip removal, make sure the fast drilling speed. Spend about 12 seconds for a hole drilling, see the test video.

4. High Hardness Standard: The hardness of drills are 48-51 degrees in my company, higher than the general manufacturers of 45-48 degrees standard. At the same time, it takes into account the

toughness and is not easy to break.

5. Quality stability: incoming inspection, 5 steps of process acceptance and finished product broken

testing , to ensure the quality stability.

Raw material advantages:

1. Grade of raw materials: the alloy used by our company is the highest grade raw material, such as

diameter 12mm, just have 422 pcs per kilogram.

2. Alloy R & D: In 2019, my company has invested about RMB 200,000 in alloy research and development, and has our own alloy appearance patent. And enjoy the priority supply of all new

products developed by the alloy factory.

3. Incoming inspection: our company has established its own alloy acceptance standard. From March to August 2020, more than 20 batches of incoming materials have been inspected for only 6mm. All unqualified alloys will be returned.

4. Our company has its own drawing plant, and the source of steel raw materials is reliable. Give priority to supply our products and guarantee the delivery time

Core equipment and technical advantages :

1. Equipment advantages: all processes are completed by ourselves from the beginning to the end, and do not rely on external processing.

2. High degree of automation: 90% of the equipment in my factory is fully automated, with automatic cold heading machine, automatic instrument, automatic groove milling , automatic cutting, automatic welding, automatic welding and other equipment. The full automation rate is in the leading position in China.

3. Core welding technology: after decades of repeated research on welding flux, welding time, welding temperature and welding quality, we have mastered the core welding datas. Ensure that there is no bias welding, no missing welding and no alloy dropping in case of high temperature.

4. Core quenching technology: the heat treatment time is about 3-4 hours. Through the automatic mesh belt quenching furnace, the temperature and the time of heat treatment are strictly controlled. Also we have secondary tempering process . what’s more, the strict product placement standard is added to realize the double guarantee of product hardness and toughness (see the picture of our company's product placement ).

5. Chip removal technology: repeatedly study and summarize the spiral width, depth, span and direction of starting and closing, we formulate different screw standards for different products, to achieve the optimal chip removal and not easy to break.

Other guarantee of our factory:

1. Delivery guarantee: for orders below 500,000pcs, the delivery time is generally controlled within 30-60 days. There is no delay in delivery.

2. Factory stability: the product line is simple, the target is clear, and the expansion is not blind. From the establishment to now, our factory are steadily rising.

3. Customer competitiveness: our company stipulates that the sales target of single market shall not be exceed RMB 10 million, so as to ensure that our customers can enjoy sufficient

competitiveness. https://furong.en.alibaba.com/contactinfo.html

4. Customized service: OEM and ODM are accepted in our factory.

Trade Assurance

Exhibition

Certification

FAQ

|

Packaging & Shipping

|

|

2.Outer packing: as requirements

|

|

3.Standard shipping marks on carton: as requirements.

|

|

4.We are also ready to provide the customized packing, such as color plastic bag, color boxes, label stick, etc.

|

|

5.Fumigation-free wooden pallet can be provided if necessary.

|

|

|

|

Shipping & payment:

|

|

1.Delivery way can be appointed by buyers or recommended by us.

|

|

2.Sea freight, Air freight, DHL, UPS, FEDEX, TNT and etc.

|

|

3.Lead time: 1 to 6 weeks depends on buyers’ purchase order quantity and special requirements.

|

|

4.Time of sea or air freight: depends on destination address.

|

|

5.Payment: T/T, western union, Paypal.

|

|

|

|

Our Services

|

|

1.Response time within 24 hours

|

|

2.Quick and on time shipment

|

|

3.Technical support

|

|

4.Product drawings and pictures available for customer's catalog design.

|

|

|

|

FAQ

|

|

1.Can you customize the products according to samples or drawing design?

|

|

-Yes. We have professional engineers to support the customized products for our customers.

|

|

2.Can you put our company's logo on the products?

|

|

-Yes. we can put your logo if you can provide us with copyright and letter of authority.

|

|

3.Can you customize our packing?

|

|

-Yes. please let us have your packing design or packing idea.

|

|

4.Do you offer free samples for checking the quality?

|

|

-Yes, the universal size is available for samples, but freight has to be paid by buyers

|

Hot Searches