- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

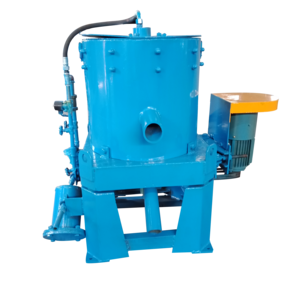

Centrifuge Separator

-

Other name:

-

Centrifugal concentrator

-

Feeding size:

-

0-5mm

-

Feeding density:

-

0-50%

-

Capacity:

-

1-100 Tons / Hour

-

Slurry water:

-

1-120 M3/h

-

Fluidization:

-

2-80

-

Recovery rate:

-

70%-90%

-

Usage:

-

Gravity Ore Separator

Quick Details

-

Production Capacity:

-

90% high recovery rate

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

GaoXuan

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Centrifuge Separator

-

Other name:

-

Centrifugal concentrator

-

Feeding size:

-

0-5mm

-

Feeding density:

-

0-50%

-

Capacity:

-

1-100 Tons / Hour

-

Slurry water:

-

1-120 M3/h

-

Fluidization:

-

2-80

-

Recovery rate:

-

70%-90%

-

Usage:

-

Gravity Ore Separator

Product Description

Instroduction of Concentrator Centrifugal Equipment

Gold Concentrator Centrifugal is also a Mining Separator Machine that was patented in China,which is similar to Knel son Gold

Centrifugal Concentrator . It is an efficient machine that is used for Mineral Separator/Gravity Separator/Gravity Separation

Process Plant . It is most especially useful for recovering fine gold which gets lost during the operation of gravitational

concentrators. It is not only used for placer gold mining, but it can also be used for the recovery of natural gold from rocks

that are hard, for replacing amalgamation and recovering of gold from the tailings.

Centrifugal Concentrator . It is an efficient machine that is used for Mineral Separator/Gravity Separator/Gravity Separation

Process Plant . It is most especially useful for recovering fine gold which gets lost during the operation of gravitational

concentrators. It is not only used for placer gold mining, but it can also be used for the recovery of natural gold from rocks

that are hard, for replacing amalgamation and recovering of gold from the tailings.

The quick -weaar parts

1) Feeding tube: There are two material available to select: a. Stainless steel: Normal used with competitive price b. PU: More

durable with higher price 2) Oil seal 3) V-belt etc

1) Feeding tube: There are two material available to select: a. Stainless steel: Normal used with competitive price b. PU: More

durable with higher price 2) Oil seal 3) V-belt etc

Concentrator Centrifugal Equipment Advantages:

High recovery and high concentrating ratio;

Recovery performance is steady;

Has a centre discharge design that enables fast and secure concentrate removal;

Eco friendly ( needs no reagents or chemical additives);

Low electricity and low water requirements;

Low cost of production, low maintenance requirements with durable wear parts;

Has a compact design needing less space and can be easily merged into an existing mining processing;

Fast returns on investment, usually less than 6 months.

High recovery and high concentrating ratio;

Recovery performance is steady;

Has a centre discharge design that enables fast and secure concentrate removal;

Eco friendly ( needs no reagents or chemical additives);

Low electricity and low water requirements;

Low cost of production, low maintenance requirements with durable wear parts;

Has a compact design needing less space and can be easily merged into an existing mining processing;

Fast returns on investment, usually less than 6 months.

Specification

It can customize with portable wheel

For gold, tin processing plant, there also widely combine with shaking table for concentration. It can customize with portable

wheel for easier move/operate.

For gold, tin processing plant, there also widely combine with shaking table for concentration. It can customize with portable

wheel for easier move/operate.

|

Model

|

Capacity (t/hr)

|

Feeding Size(mm)

|

Feeding Density(%)

|

Power Requirement

(kw) |

Cone Rotate Speed

|

Water Required(t/h)

|

Dimension(mm)

|

|

STLB20

|

0.5-1.0

|

0-2.5

|

0-50

|

1.1

|

800

|

1.5-2.0

|

800*560*710

|

|

STLB30

|

2.0-3.0

|

0-4

|

0-50

|

2.2

|

600

|

4.0-6.0

|

1280*1030*1135

|

|

STLB60

|

8.0-12.0

|

0-6

|

0-50

|

7.5

|

460

|

10.0-15.0

|

1850*1550*1600

|

|

STLB80

|

10.0-20.0

|

0-6

|

0-50

|

15

|

400

|

17.0-25.0

|

2300*1800*2200

|

|

STLB100

|

50-100

|

0-6

|

0-50

|

18

|

360

|

40.0-60.0

|

2400*2400*2250

|

Packing & Delivery

Hot Searches