Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

JIANGSU

-

Brand Name:

-

FRIEND MACHINERY

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

30

-

Weight:

-

10000 KG

-

Raw material:

-

PP PE Granules

-

Capacity:

-

150-250kgh

-

Motor:

-

SIEMENS Brand

-

Extruder:

-

65 Single Screw Extruder

-

Inverter:

-

ABB Brand

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

150 rpm

-

Place of Origin:

-

JIANGSU

-

Brand Name:

-

FRIEND MACHINERY

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

30

-

Weight:

-

10000 KG

-

Raw material:

-

PP PE Granules

-

Capacity:

-

150-250kgh

-

Motor:

-

SIEMENS Brand

-

Extruder:

-

65 Single Screw Extruder

-

Inverter:

-

ABB Brand

-

Certification:

-

CE ISO

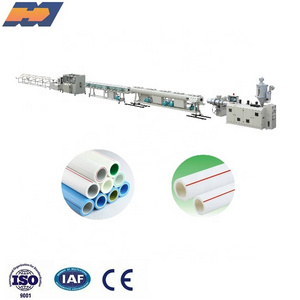

PE PPR 3 Layer pipe extrusion line 20-110mm plastic PE HDPE PPR pipe making machinery/HDPE production line/Plastic extruder

This line is used to produce PPR glass fiber reinforced pipe by single screw extruder.

The raw material is PPR

,PE

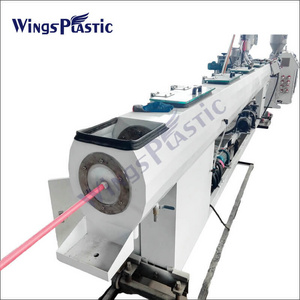

Process Flow of PE PPR pipe machine

Raw material +master batches → mixing→vacuum feeding → material dryness → single screw extruder → single screw extruder → single screw extruder → color string extruder → spiral co-extrusion mould → calibrator → spray vacuum calibration tank → spray cooling water tank → spray-code printer → belt haul-off → no-dust cutter → pipe rack→finished product inspecting &packing

Mian machine list

|

No. |

Item |

Qty |

|

1 |

SJ65 plastic extruder |

3 SETS |

|

2 |

SJ25 plastic extruder |

1 SET |

|

3 |

Co-extrusion mold |

1 SET |

|

4 |

Vacuum forming box |

1 SET |

|

5 |

Cooling spray tank |

1 SET |

|

6 |

Haul-off machine |

1 SET |

|

7 |

Cutting machine |

1 SET |

|

8 |

Stacker |

1 SET |