- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

800*400*350MM

-

Year:

-

2024

-

Power (kW):

-

5 kW

-

Weight (KG):

-

100 KG

-

Product name:

-

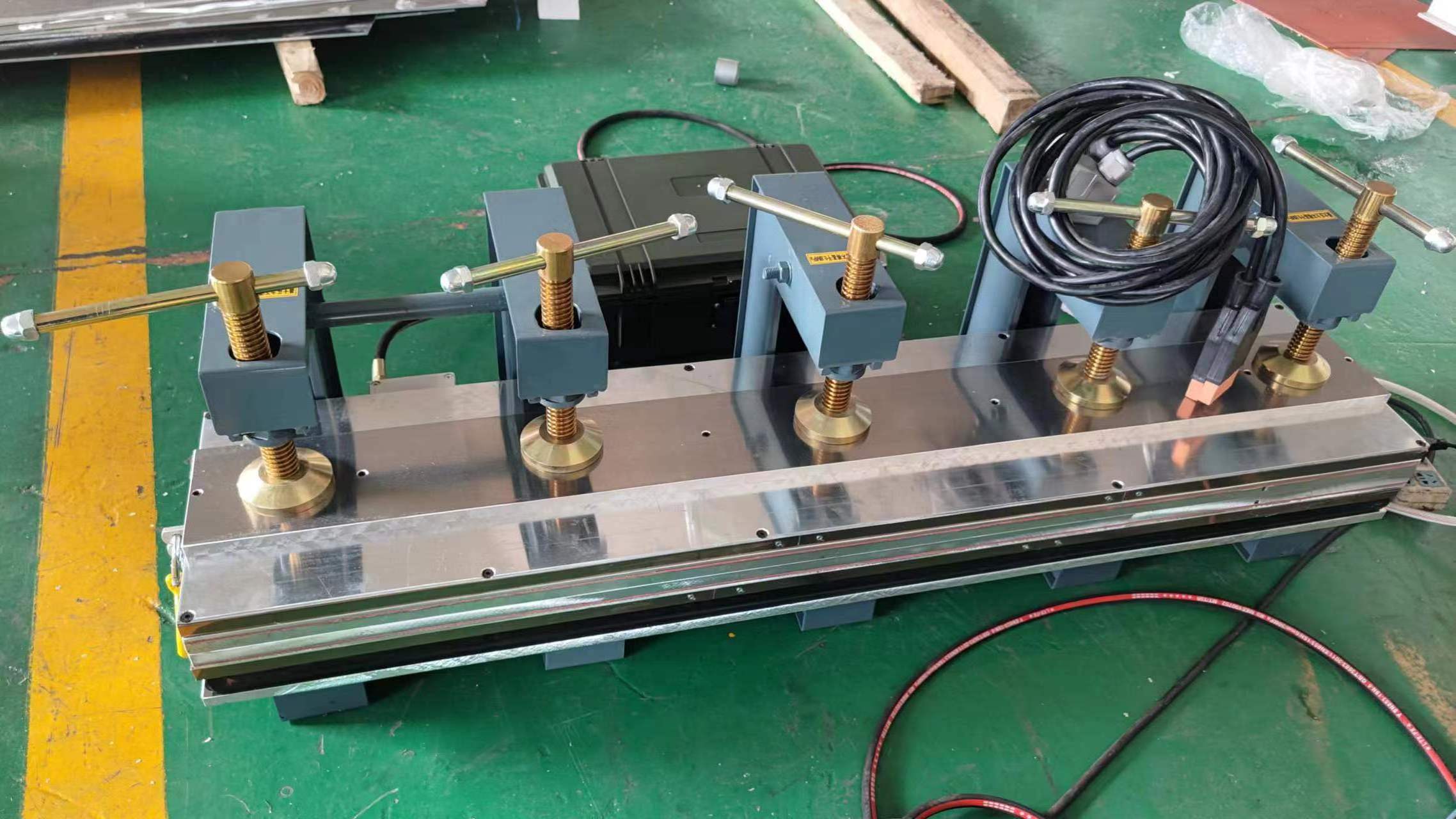

Edge repair vulcanizing press

-

Application:

-

Conveyor Belt Edge Repair

-

Machine Type:

-

Vulcanizing Press Repair Machine

-

Max Conveyor Belt Width:

-

500-3500mm

-

Material:

-

High Strength Aluminum Alloy

-

Belt Vulcanizing Temperature:

-

145℃

-

Working Pressure:

-

0~2 MPA

-

Cooling system:

-

Water Cooling

-

Heating Time:

-

Less Than 25 Minutes

-

Curing Time Set Adjustable Range:

-

0-99 minutes

Quick Details

-

Place of Origin:

-

Shandong, China

-

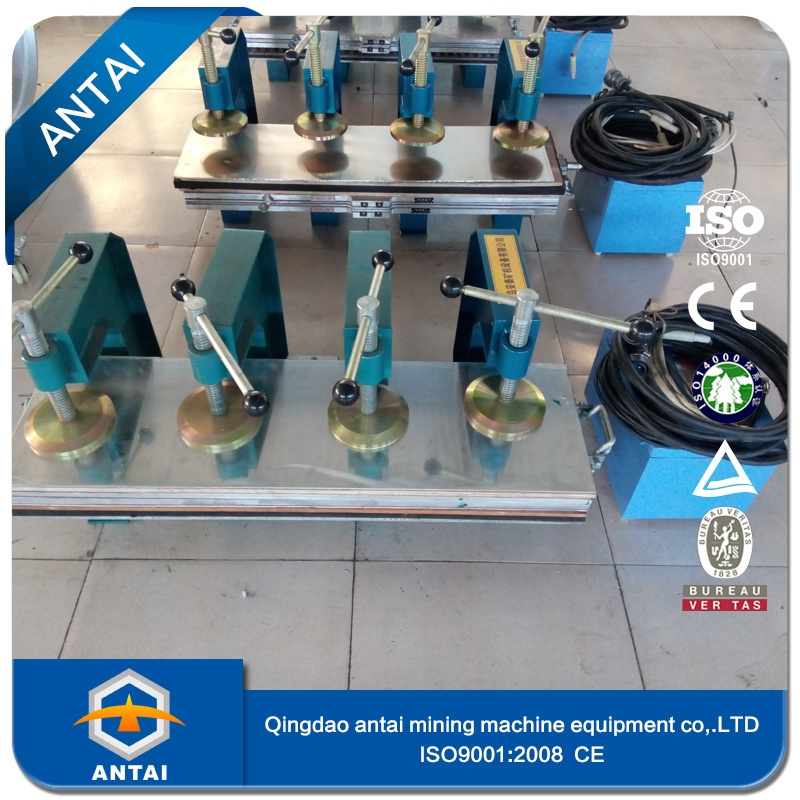

Brand Name:

-

ANTAI

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

800*400*350MM

-

Year:

-

2024

-

Power (kW):

-

5 kW

-

Weight (KG):

-

100 KG

-

Product name:

-

Edge repair vulcanizing press

-

Application:

-

Conveyor Belt Edge Repair

-

Machine Type:

-

Vulcanizing Press Repair Machine

-

Max Conveyor Belt Width:

-

500-3500mm

-

Material:

-

High Strength Aluminum Alloy

-

Belt Vulcanizing Temperature:

-

145℃

-

Working Pressure:

-

0~2 MPA

-

Cooling system:

-

Water Cooling

-

Heating Time:

-

Less Than 25 Minutes

-

Curing Time Set Adjustable Range:

-

0-99 minutes

Products Description

|

Product Name

|

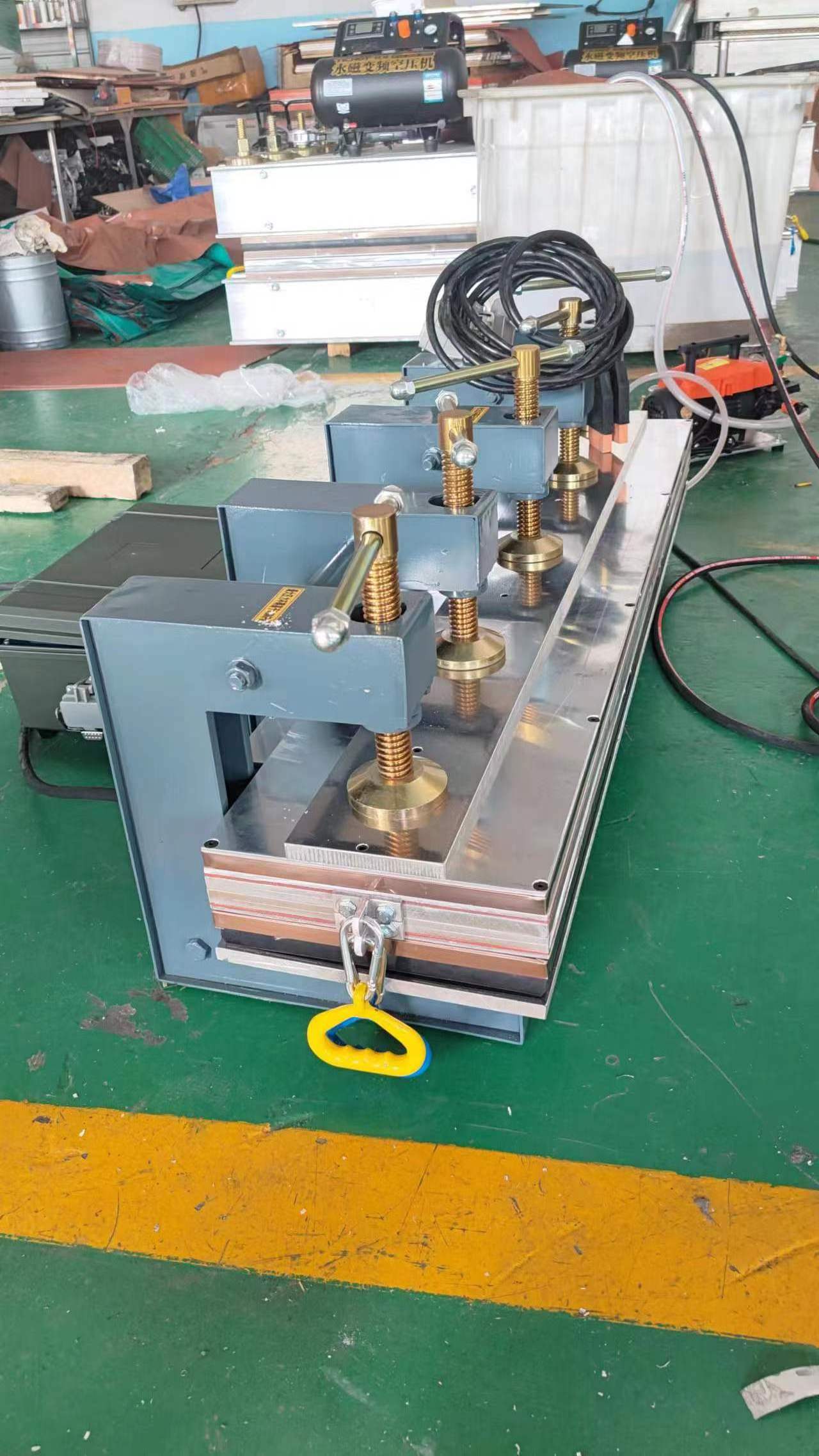

Edge Repair Vulcanizing Press Hydraulic Repair Vulcanizer

|

|

Heating system

|

Silicone Heating Blanket, Heating Time less than 15mins

|

|

Material

|

High Strength Aluminum Alloy

|

|

Working Pressure

|

0.8mpa

|

|

Cooling System

|

Water cooling

|

XL strip vulcanizing repair machine

XL strip vulcanizing repair machine ,also known as the belt-edge repair vulcanizing machine, is mainly applied to repair the long-distance damage ,longitudinal piercing as well as edge damages on the conveyor belt on site. It’s time-saving, efficient and easy operated.

Main Parts

Specification

Use Installation instructions:

1.Fill glue inthe damaged areas that need to be repaired(see the adhesive part in the vulcanization process of the belt joints, or the demonstration by our staff when the equipment is being tested);

2.Put the bottom plate, water pressure plate and lower heating plate under the damaged areasof the belt according to the structural diagram.

3.Put the upper heating plate,Insulation board on the damaged areasof the belt.Align the top and bottom plates.

4. Lockedequidistantlythen tighten the bolts.

5.Get the first power wire well connected to electric control box. Connect the second wire with electric control box and the upper and down plates.Note that it corresponds to the signon the electric control box.

6.Connect the end of the high pressure pipe with inlet opening of water pressure plate. And connect another end of the high-pressure pipe with water output hole of water pump.Switch on, add pressure upon vulcanizing machine.

(See the operation method of ATX electric control box).

2.Put the bottom plate, water pressure plate and lower heating plate under the damaged areasof the belt according to the structural diagram.

3.Put the upper heating plate,Insulation board on the damaged areasof the belt.Align the top and bottom plates.

4. Lockedequidistantlythen tighten the bolts.

5.Get the first power wire well connected to electric control box. Connect the second wire with electric control box and the upper and down plates.Note that it corresponds to the signon the electric control box.

6.Connect the end of the high pressure pipe with inlet opening of water pressure plate. And connect another end of the high-pressure pipe with water output hole of water pump.Switch on, add pressure upon vulcanizing machine.

(See the operation method of ATX electric control box).

The equipment can be customized as two type: oil pressure and water pressure.

Product packaging

We use fumigation-free box as our packing box.It has clean and tidy appearance,easy to load and unload.Comply with the export standards of the customs.

Customer Photos

Our Plant

Certifications

We are the Direct Manufacturer of conveyor belt vulcanizing equipment. Our company is the direct manufacturer supplier in China for the production of the pressurized bag. ALMEX STYLE available,with lower ANTAI price.

Yes! We promise you the lowest price in China. In case of the higher price you may get from our domestic trading company Please keep in touch with me.

C

ontact with me

If you need the latest catalogue of our conveyor belt vulcanizing press or have any problem about our products,please feel free to contact with me. I will do my best to provide you our professional service.

Here is my EMAIL address:

sherry@antai86.com (Sales manager of ANTAI OVERSEAS DPT)

TEL: +86 15665751353

PHONE: +86 15665751353

Hot Searches