- Product Details

- {{item.text}}

Quick Details

-

Max. feeding size:

-

25mm

-

Chamber qty:

-

2 Chambers

-

Capacity:

-

10-25 T/H

-

Chamber Area:

-

2㎡

-

Other model:

-

100*150mm; 300*450mm; 370*360mm; 670*920mm;

-

After sale service:

-

Supply set up video, dispatch engineer if need

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Product name:

-

1000*1000 Gold Separator Machine

-

Application:

-

tungsten, tin, iron, manganese and chrome ore;

-

Max. feeding size:

-

25mm

-

Chamber qty:

-

2 Chambers

-

Capacity:

-

10-25 T/H

-

Chamber Area:

-

2㎡

-

Other model:

-

100*150mm; 300*450mm; 370*360mm; 670*920mm;

-

After sale service:

-

Supply set up video, dispatch engineer if need

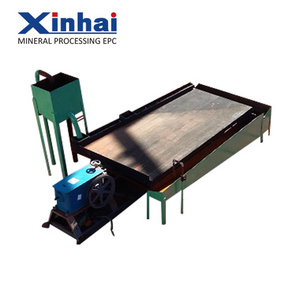

Diaphragm Diaphragm Jig has the advantage of simple operation , large capacity, and can obtain the final concentration or the tailing in one beneficiation.

It is widely used in dealing with the coarse or medium-grained ore.

It is suitable for classification the larger differential density of tungsten, tin, iron, manganese and chrome ore ; Also for ferrous metal and non-ferrous metals containing the gold and rare metals.

Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine

Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine

Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine

Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine Gold Separator Machine

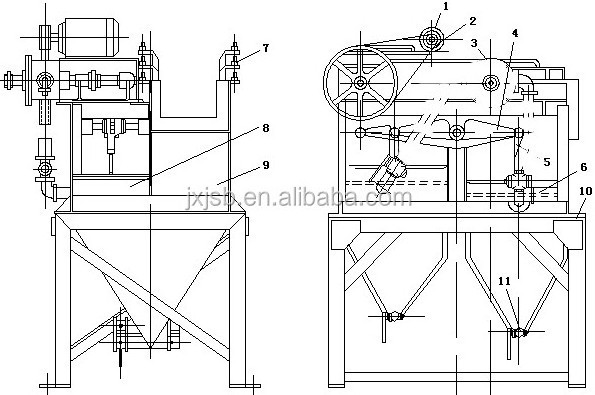

1,

Motor

2,

Transmission Sets

3

, Separator

4,

Rocker Arm

5,

Link

6,

Rubber Diaphragm

7, Feed Chamber 8, Diaphragm Chamber 9 , Jigging Chamber 10 , Frame 11 , Output Port

There are two jig buckets with different sizes and each diaphragm is divided into jig area and diaphragm area by clapboard. The rubber diaphragm pumping to make medium (water) moving is the jigging course. The triangle belt drives big belt pulley by electric motor so connecting rod of the eccentric gear and rocker are up and down moving. Another connecting rod is connected with the rubber diaphragm which is moving up and down to jig.

|

Model |

Chamber No |

Jig area m 2 |

Feed Size mm |

Capacity t/h |

Stroke mm |

Frequency r/min |

Power kw |

|

100×150

|

1 |

0.15 |

<3 |

0.18-0.6 |

0 |

420 |

0.55 |

|

300×450

|

2 |

0.27 |

< 12 |

3-6 |

0-26 |

322 |

1.1 |

|

370×360

|

2 |

0.26 |

< 6 |

1-3 |

5-25 |

200-250 |

1.1 |

|

670×920

|

2 |

1.44 |

4-8 |

7-10 |

18-24 |

240-300 |

1.1

|

|

1000*1000 |

2 |

2 |

1-5 |

10-25 |

0-26 |

200-350 |

1.5 |