- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DR102

-

Brand Name:

-

DR

-

Material:

-

Steel alloy

-

Name::

-

5 Axis Precision CNC Machined Turbocharger Impeller

-

Process:

-

casting + machining

-

Surface treatment:

-

polish

-

Weight:

-

0.05kg - 0.9kg

-

Heat treatment:

-

Normalized / Annealed / Quenched / tempered

-

Dimensions:

-

OEM & CNC Machining

-

Application:

-

industry

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Hardened Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

DR102

-

Brand Name:

-

DR

-

Material:

-

Steel alloy

-

Name::

-

5 Axis Precision CNC Machined Turbocharger Impeller

-

Process:

-

casting + machining

-

Surface treatment:

-

polish

-

Weight:

-

0.05kg - 0.9kg

-

Heat treatment:

-

Normalized / Annealed / Quenched / tempered

-

Dimensions:

-

OEM & CNC Machining

-

Application:

-

industry

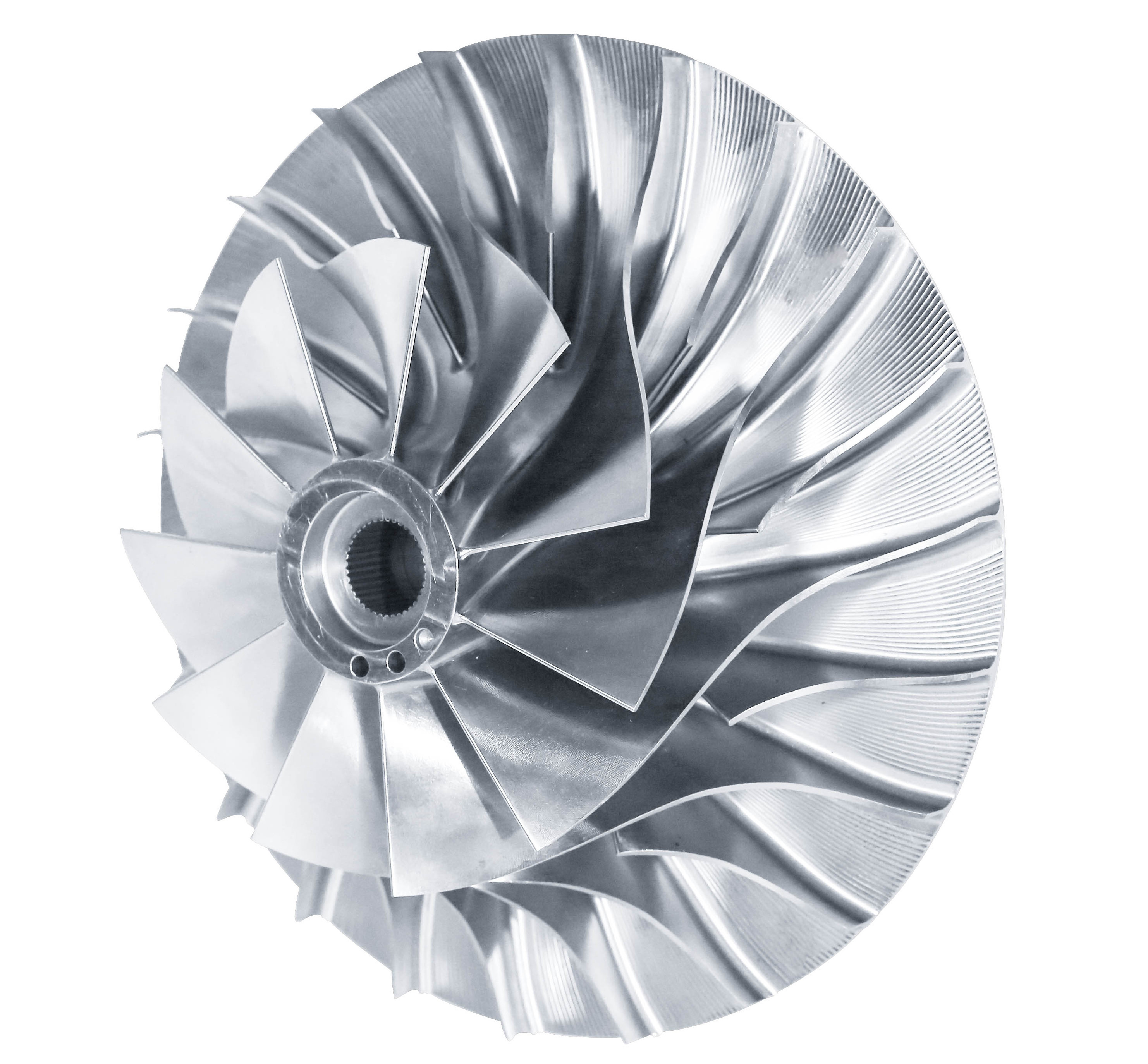

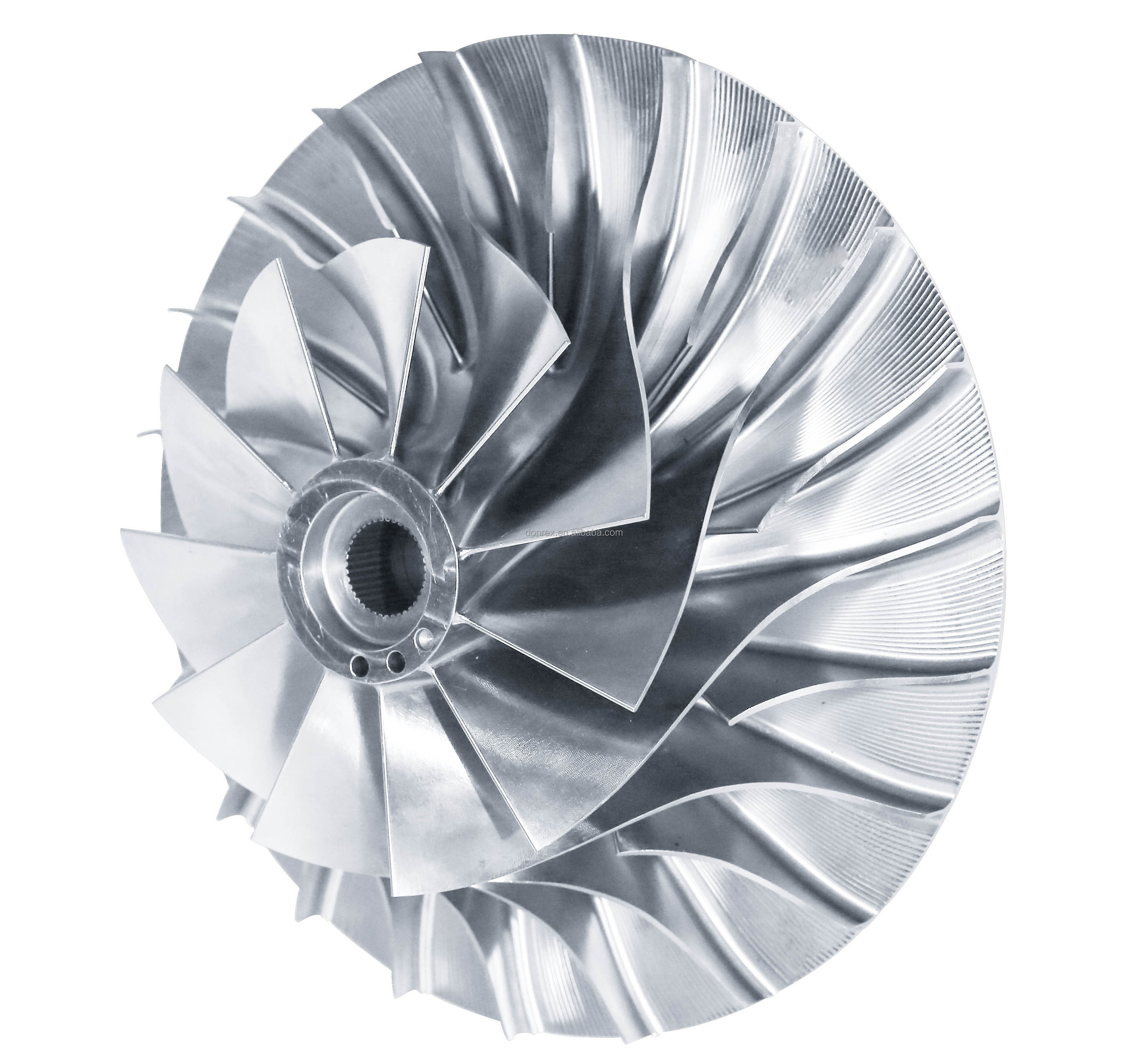

5 Axis Precision CNC Machined Alloy Steel Turbocharger Impeller

- Designed and processed by CNC machine.

- All big and small angles are well finished.

- Precision alignment sleeves positively locate the rod cap, maintaining big end bore size and eliminating cap walk.

- X-rayed, sonic tested and magnafluxed.

- Multi-stage heat treated.

- Shot peened to relieve stress.

- Come with the bronzed bushing suitable for the floating piston pin.

Product Advantages

1. Excellent Internal Organization Structure

After forging procedure and hot working, the internal structure of forging part has been deformed

and recrystallized, which makes the internal structure become more and more tightly. As a result, the

forging part has an excellent internal organization structure and improve its property greatly.

2. Outstanding Mechanical Property.

Since the forging process guarantees the continuity of the metal fiber organization, the internal

organization of forging part brings into correspondence with its appearance. Consequently, the metal

flow is quite complete. And this makes the forging part has an outstanding mechanical property and

also a long usage life.

3. Cost effective and economically.

Through forging procedure, the shape of forged part is very close to the finished product. Thus

there is little machining allowance left . And this r educes its processing cost and makes it very cost

effective .

4. Widespread usage.

Because the forging parts have lots of advantages, they are widely used in the metallurgy, mining,

machinery, chemical, auto, aviation, and ship hardware and so on.