- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

14KG

-

Water temperature:

-

less than 100 centigrade

-

Descaling efficiency:

-

98%

-

Lifespan:

-

15 years

-

Magnetic field strength:

-

>800 gauss

-

Prevent scale rate:

-

≥85%

-

Interface type:

-

thread or flange

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dejieli

-

Material:

-

metal, Stainless steel

-

Weight:

-

14KG

-

Water temperature:

-

less than 100 centigrade

-

Descaling efficiency:

-

98%

-

Lifespan:

-

15 years

-

Magnetic field strength:

-

>800 gauss

-

Prevent scale rate:

-

≥85%

-

Interface type:

-

thread or flange

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support

Product Description

Circulating cooling water is widely used in daily life and industrial production. The scaling of circulating water has seriously plagued users. After the scaling of circulating water, the heat exchange efficiency decreases, which not only causes energy waste but also causes pipeline blockage or flow reduction, and even affects the quality of production products,etc., has become a very difficult problem in factory management.

Causes of scaling:

As the water temperature increases, the solubility of calcium carbonate and calcium sulfate in the water decreases, and scale is easy to form.

As the water temperature increases, the calcium bicarbonate Ca(HCo3)2 and magnesium bicarbonate (Mg(HCo3)2) dissolved in the water are easily converted into insoluble calcium carbonate (CaCo3) and magnesium carbonate (MgCo3) and release CO2

, This is the cause of scale.

Ca(HCo3)2= CaCo3+H2O+CO2

Dejieli has focused on quenching and cooling for 18 years, and is committed to providing customers with cooling system solutions. Aiming at the pain points of circulating cooling water scaling, after the company's internal testing for 3 years, it has developed a descaling instrument to help you effectively inhibit the growth of scale. The equipment is environmentally friendly and energy-saving, the equipment has no operating loss, no noise, no need for special supervision, economical and environmentally friendly; at the same time, it is economical and practical, easy to install, and easy to operate.

Specifications

Size specification table (JIS10KG/cm2) type

| model |

inner diameter |

external diameter |

Thickness |

centre |

the size of the hole |

the number of the hole |

screw |

|

DJL-3C |

90mm |

1 85mm |

1 8mm |

1 50mm |

1 9mm |

8 mm |

5 /8 |

|

DJL-4C |

116mm |

210mm |

1 8mm |

1 75mm |

1 9mm |

8 mm |

5 /8 |

|

DJL-5C |

1 42mm |

2 50mm |

2 0mm |

2 10mm |

23mm |

8 mm |

3 /4 |

|

DJL-6C |

1 67mm |

2 80mm |

2 2mm |

2 40mm |

23mm |

8 mm |

3 /4 |

|

DJL-8C |

2 18mm |

3 30mm |

2 2mm |

2 90mm |

23mm |

8 mm |

3 /4 |

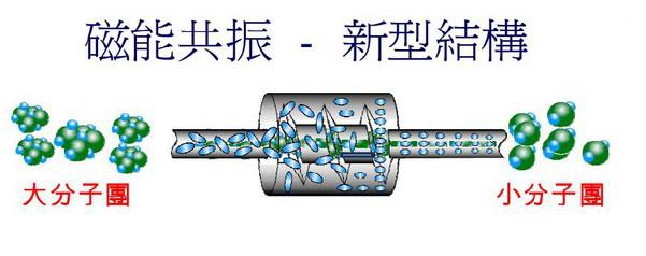

Principle description of the descaling instrument :

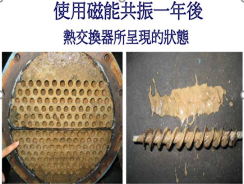

Before using the descaling instrument After using the descaling instrument for one year

After the water molecules are strongly magnetized, their chemical and physical properties are changed.

- The angle between the hydrogen and oxygen bonds of water molecules becomes smaller, and the water molecules become smaller, which is beneficial to the washing of tiny impurities and the absorption of cells.

- Improve the surface tension of water, the conductivity of water, the solubility of water, the amount of oxygen in the water, the magnetization energy, and the active water can promote the activation of skin cells.

- The strong magnetic field transfers energy to the water, destroys the hydrogen bond in the water and the hydrogen bond between water and HCO3, increases the chance of collision between H+ and CO3-2 ions, reduces the stability of CaCO3, and turns hard dirt into soft mud. Easy to remove sewage. For example: water with a hardness of 50~400mg/l, after being magnetized, can reduce deposits by 92% and has the effect of preventing structure.

Design of the descaling instrument :

- During the magnetization process, the phenomenon of turbulence and stirring appears, which has the effect of homogenizing and mixing the fluid

- Extend the magnetization time, so that the fluid fully absorbs the magnetic energy, and the descaling power is doubled

- The strong magnetic field transfers energy to the Ca2+/Mg2+ in the water, turning into negatively charged Ca-/Mg- ions, which will not combine with carbonate/silicate/sulfate in the water to form dirt.

- The circulating water is continuously processed by the magnetizer, and there is no need to add any chemical substances, and to maintain the Ca-/Mg- ion state, only the water needs to be regularly drained (the frequency of water is about 1/5,) is environmentally friendly and saves money.

Selection of the descaling instrument :

In order to prolong the magnetization time, a spiral blade is designed inside the machine. When the water passes through the scaler, it will block the water flow. When selecting the descaling instrument , please refer to your existing pipe + 1 inch selection , That is, if you use a 3-inch water pipe, you can choose a 4-inch scaler to meet your requirements.

Customer site case

The mesh belt furnace plate heat exchanger has been used for three years. After being removed, there is a lot of sludge on the oil side, and almost only a thin layer of powdery tissue on the water side.

oil side water side

Installation method

There are three ways to install:

1,Straight-through: (4-inch PVC pipe)

2,Pipe bonding flange type: (4-inch PVC pipe)

3,Direct flange type: (4-inch iron pipe)

Straight-through installation procedures:

1. Cut the original 4-inch PVC pipe to be installed to a length of 850mm. Mark the 60mm marks at both ends;

2. Loosen the screws on both sides of the scaler;

3. Apply glue to the outside of the PVC pipe and the inside of the two ends of the scaler respectively;

4.The scaler distinguishes the water inlet and outlet directions, insert the PVC end first, and then insert the other end;

5. Look at the mark to adjust the distance of each insertion on both sides, and rotate the LOGO outward (intuitive);

6. Add glue to the outside of the interface, and tighten the screws on both sides for reinforcement;

Pipe bonding flange type installation rules:

1. Cut 850mm length on the original 4-inch PVC pipe, cut straight, and chamfer the nozzle. Then mark the 60mm mark at both ends;

2. Connect the flange from 4 inches to 5 inches, and pass through the glue to the end;

3. Apply glue to the outside of the PVC pipe and the inside of the flexible interface respectively, and first connect the flange to the original PVC pipe first, and see the mark;

4. Quickly adjust the screw holes of the flange to be straight, which is convenient for the flange hole of the scale!

5. Distinguish the water inlet and outlet directions of the scaler, install them in parallel, and remember: plug the two ends into the sealing gasket;

6. Turn the LOGO outwards (intuitively) and tighten the screws. Replenish the glue at each glue joint to strengthen it;

7. Suspended shaking requires additional reinforcement.