- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380/220V

-

Dimension(L*W*H):

-

1900X1300X1200

-

Weight:

-

3000 KG

-

Product name:

-

Gold Wash Plant

-

Application:

-

Alluvial Gold Washing

-

Name:

-

Gold Mining Washing Machine

-

Keywords:

-

Alluvial Gold Mining Machine

-

Installation:

-

Dispatch Engineer

-

Usage:

-

Gold Gravity Concentrate

-

Model:

-

LS4500/6S4500/LY2100/LY3000/LY1100

-

Motor:

-

Siemens Motor

-

Recovery rate:

-

95-98%

Quick Details

-

Production Capacity:

-

10 to 500 ton per hour

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ascend

-

Voltage:

-

380/220V

-

Dimension(L*W*H):

-

1900X1300X1200

-

Weight:

-

3000 KG

-

Product name:

-

Gold Wash Plant

-

Application:

-

Alluvial Gold Washing

-

Name:

-

Gold Mining Washing Machine

-

Keywords:

-

Alluvial Gold Mining Machine

-

Installation:

-

Dispatch Engineer

-

Usage:

-

Gold Gravity Concentrate

-

Model:

-

LS4500/6S4500/LY2100/LY3000/LY1100

-

Motor:

-

Siemens Motor

-

Recovery rate:

-

95-98%

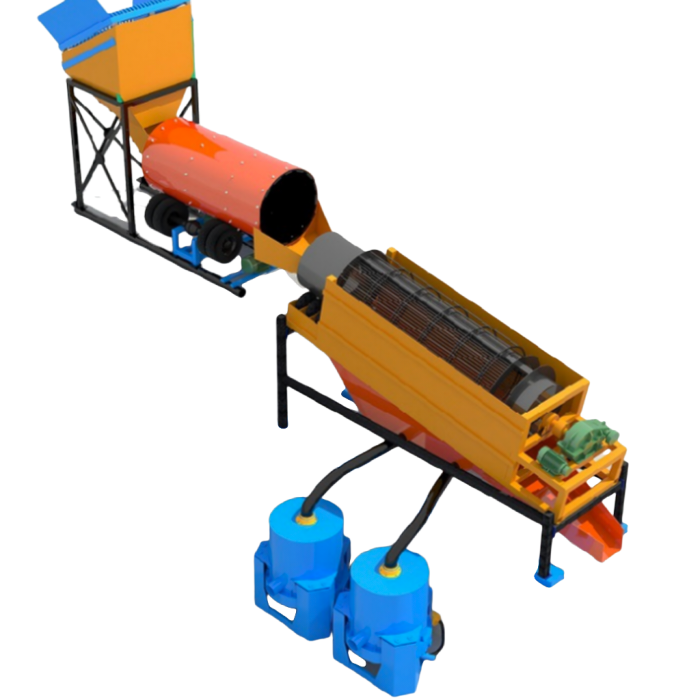

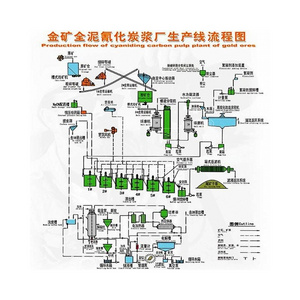

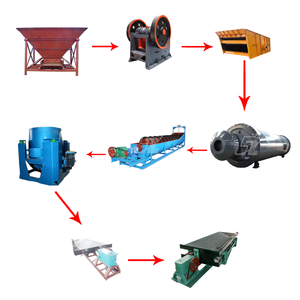

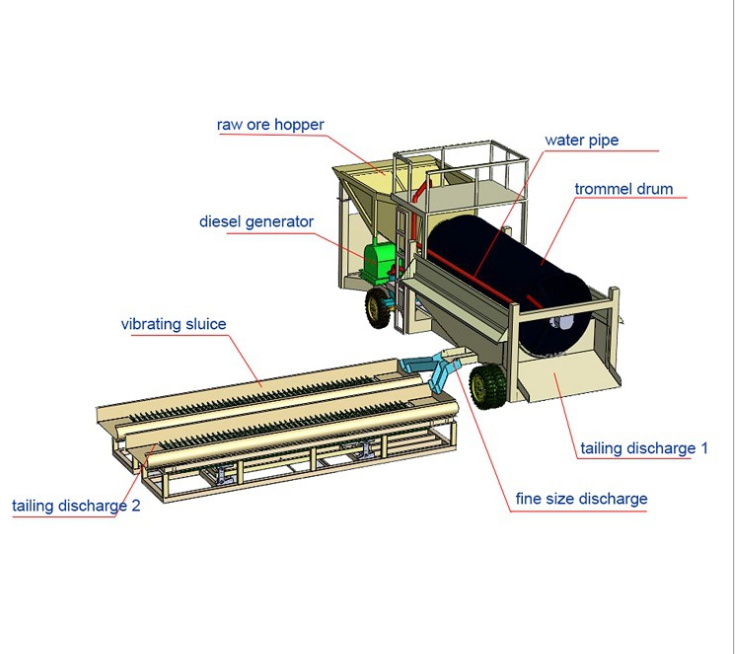

Small Scale Mining Gold Ore Process Washing Plant

The placer gold trommel screen washing plant can be mobile type or fixed type, It is mainly used to washing, and select the particle or powder gold in the river sand or gravel. It is a complete set inlcuding the feeding hopper, trommel screen or vibrating screen, water pump and high pressure water spray gun, gold centrifugal concentrator, gold sluice and other accessories.

Features of Drum Scrubber Washing Machine

-Good washing effect for sticky clay material, sieving out different size ores.

- Various Process capacity , can be from 5 T/H to 250T/H as per request

- Low operating cost, easy maintenance, low noise.

-The length &diameter of Gold Trommel drum , inside drum lined material, screen mesh, layer quantity of screen and Screen material can be customized.

-mobile type or stationary type Gold Trommel

-diesel generator or electric motor for Gold Trommel

Main Structure of Drum Scrubber Washing Machine

1.Gold Trommel Drum : For washing sticky clay from ore.

2.Inside drum lined plate: for breaking the clay and ores, wash more clean the material, can be rubber lined plate or iron steel plate welded inside drum

3.Sieving Screen of Gold Trommel Washing Machine : for sieving different sizes ores, the screen mesh size& layer quantity & screen materials can be customized, screen material can be manganese steel or stainless steel. Mostly use manganese steel

4.Motor: Electric Motor or diesel according to request.

5.Reducer: works together with motor and bearing for transmission drum rotating.

6.Gold Trommel Base Frame: Supporting the whole trommel scrubber

Advantages of gold trommel equipment:

1.It is a highly economically viable option adequately suitable for small to large volume processing of materials.

2.The screen features various filters for different heavy duty drums that ensure complete separation of fine materials.

3.The design has a end user flexibility that allows for screen replacements depending on mesh sizes

4.Multiple layers of screen to enhance the sifting process.

5.It features changeable screen plates so that worn out parts can be replaced.

6. Trommel screen has high efficiency and a big capacity for different volumes of materials

7.The screen is uniquely designed to facilitate higher capacities, provide longer screen life and avoid material clogging.

The trommel screen is equiped with water spray pipe inside drum, with feeding hopper, water pump, diesel generator,ect

Description of the placer gold washing plant.

After finishing installtion of the whole plant. Usually use excavator or payloader to feed the river sand into the hopper, then the sand go to the trommel screen. When the rotary trommel screen is rotating, big size more than 8mm sand will be screened out, small sizes less than 8mm will go to the gold centrifugal concentrator or vibrating gold sluice ( usually we recommend concentrator, as it can achieve high recovery rate for different gold particle sizes from 40 mesh to 200 mesh). Following the concentrator is gold sluice with gold blanket, which is used to recover the remaining gold in the concentrator.

Specification

|

SPECIFICATIONS OF GOLD EXTRACTION EQUIPMENT FOR WASHING GOLD SEPARATOR MACHINE |

||||

|

Model |

GTS20 |

GTS 50 |

MGT100 |

MGT200 |

|

Parameters |

|

|||

|

Size /mm |

6000x1600x2499 |

7000*2000*3000 |

8300*2400*4700 |

9800*3000*5175 |

|

Capacity |

20-40 |

50-80 tph |

100-150 tph |

200-300 tph |

|

Power |

20 |

30 kw |

5 0 kw |

8 0 kw |

|

Trommel Screen /mm |

1000x2000 |

φ1200*3000 |

φ1500*3500 |

φ1800*4000 |

|

Sluice Box |

2 set |

2 sets |

3 sets |

4 sets |

|

Water Supply /m³ |

80m³ |

120 m³ |

240 m³ |

370 m³ |

|

Recovery Rate |

95% |

98% |

98% |

98% |

Gold sluice with blanket

Shaking table

After collect the gold concentrate fromo the centrifugal concentrator and gold sluice blanket, the most common way is then put it on the shaking table to further improve the gold grade.

Mercury Amalgamation barrel or small ball mill.

The gold ore concentrate collected from the shaking table will be put in the small ball mill, or we call it mercury amalgamation barrel. Then it can mix with the mercury and form the gold and mercury mixture.

Electric gold melting furnace

After get the mixture of gold and mercury, you can put it in the elctric gold melting furnace and heat it, then you can get the pure gold bar.