- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customized

-

Power:

-

0.75kw

-

Weight (KG):

-

4200

-

Name:

-

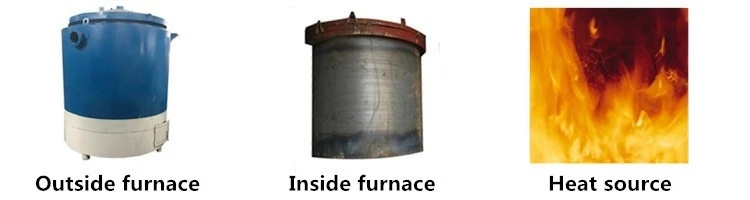

Carbonization furnace

-

One machine:

-

3 inner pot + 1 outer stove + 1 hoist

-

Raw material:

-

wood briquette,coconut shell,etc

-

Working area:

-

30-50sqm

-

Temperature:

-

300-450℃

-

Cooling time:

-

0-10hours

-

Carbonizing rate:

-

20-45%

-

Keywords:

-

Charcoal Cabonization Furnace

-

Equipped With:

-

Flue Gas Purifier

-

Carbonization time:

-

6-8 Hours/batch

Quick Details

-

Place of Origin:

-

China

-

Effective Volume:

-

2.54*3m

-

Dimension(L*W*H):

-

2.3*2.1*2.5*m

-

Voltage:

-

customized

-

Power:

-

0.75kw

-

Weight (KG):

-

4200

-

Name:

-

Carbonization furnace

-

One machine:

-

3 inner pot + 1 outer stove + 1 hoist

-

Raw material:

-

wood briquette,coconut shell,etc

-

Working area:

-

30-50sqm

-

Temperature:

-

300-450℃

-

Cooling time:

-

0-10hours

-

Carbonizing rate:

-

20-45%

-

Keywords:

-

Charcoal Cabonization Furnace

-

Equipped With:

-

Flue Gas Purifier

-

Carbonization time:

-

6-8 Hours/batch

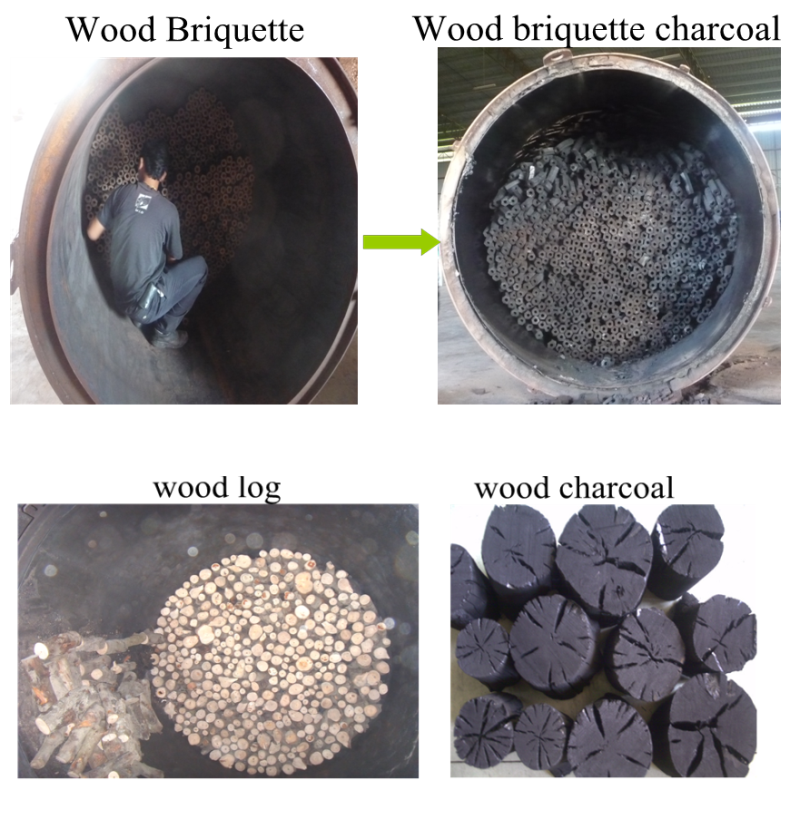

Wood Carbonization Furnace

This wood carbonization stove is an efficient stove can change wood log, wood briquette, coconut shell and bamboo Palm shells etc directly into final charcoal,can working without electricity.

Wood Carbonization Stove M ain P arts :

n Inner stove:

n Consist of the stove tank body and the sealed top cap. Both of them are made of the heat resistance thermal steel. , and the three carbonization basket can be stack together, easy for loading and transporting ,and it will save a lot of space and transport charge.

n Hoisting equipment:

n it include the steel hoisting frame and the E-hoist .And it is easy for loading and unloading the stove, and can reduce labor intensity, and it can be avoid the high-temperature burn when lift the carbonization basket.

n Purification tank:

n This system is consisting of purification tank and the exhaust-heated cycle pipe. And Smoking purification tank are used for purify the smoking

(can not Burning) and filter the wood tar.

The smoking through the purification tank will Become water vapor, and it will not pollute the air.

W orking P rinciple:

1) Arrange wood briquettes in furnace, leave 25 cm distance from the briquette to the roof of furnace

2) Close the door of furnace

3) Brn 10 kg wood briquettes, and put into furnace from the top holes.

4) Turn on the air fan

5) Leave a small gap at the top hole to supply a little air, this procedure lasts 6 hours, and during this 6 hours, make the gap smaller and smaller.

6) After 6 hours, watch the smoke from the chimney, compare the color of smoke, if the

smoke become transparent, close the gap completely.

7) Turn off the air fan.

8) Wait the stove become cool, this procedure lasts 6 to 8 hours

9) Open the door, and leave the stove, make sure the gas come out and then check if the

carbonizing is finished

10) If after 6 hours, the smoke is still strong, keep the air fan working, and leave the gap

until the smoke become transparent. Sometimes, this procedure last 8-10 hours.

11) At the end, if the carbonization is not complete, the wood briquettes don’t become

charcoal totally, ignite again, and do as the above procedure

12) The better quality of charcoal needs longer time of carbonizing, best charcoal sounds

like steel, and no smoke when burn.

Specification

|

Model Name |

Capacity |

Mainly Included Parts |

Shipping |

|

QHL -1 |

2-3ton/24hour |

1outer stove+3 inner pot |

LCL |

|

QHL-2 |

5-6ton/24hour |

2outer stove+6 inner pot |

FCL 1*20GP |

|

QHL-3 |

7-9ton/24hour |

3outer stove+9 inner pot |

FCL 1*40GP |

|

QHL-4 |

10-12ton/24hour |

4outer stove+12inner pot |

FCL 1*40GP |

Related Products

Wood Sawdust Machine Wood Briquette Machine

After-sales Service Provided

Engineers available to service machinery overseas

Free spare parts

Video technical support

Online support

Packing & Shipping

Packaging Detail: Iron pallet or wooden cases

Delivery Detail: By sea or By air

FAQ

-

Q1:What payment methods do you accept?

We support various payment methods, we can accept 30% as deposit. -

Q2:How long is your delivery time?

We have more than 1500 square meters of spot inventory workshop, and it usually takes 3-5 days for goods with sufficient inventory. If you need to customize the equipment, it takes 5-10 days. We will do our best to deliver as soon as possible. -

Q3:What if the machine is damaged?

One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales service.