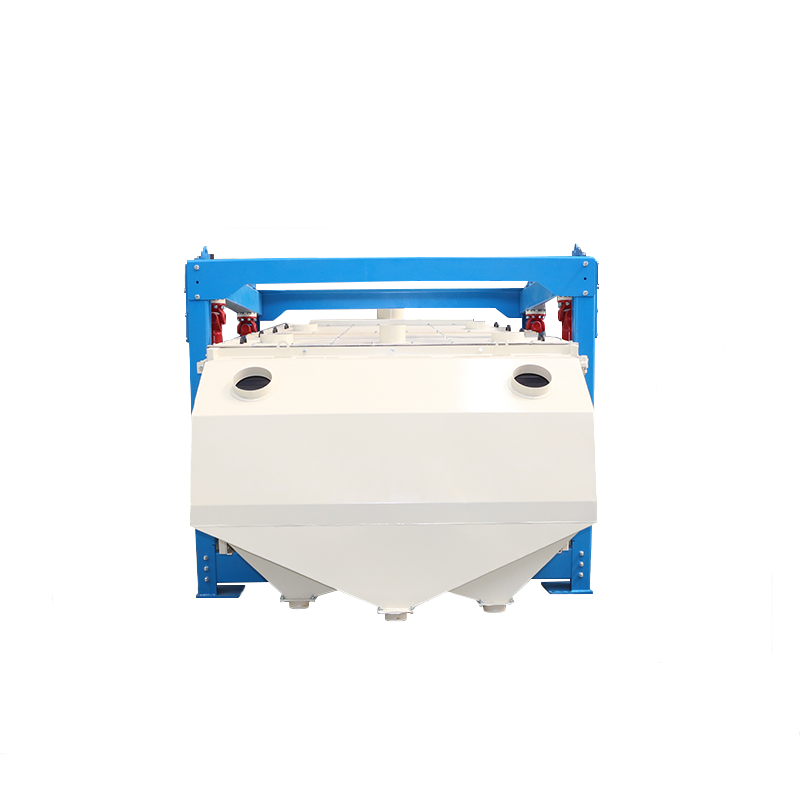

The working principle of the square tumbler screen is that after the start of the screen machine, the rocking body of the screen

machine, i.e. the screen box, moves back and forth under the action of inertia force, and the screen box drives the screen surface

to oscillate periodically, so that the material on the screen surface can make a directional jump motion with the screen box.

During this period, the material smaller than the screen aperture falls into the lower layer through the screen hole and becomes

the material under the screen, and the material larger than the screen aperture is rolled continuously.

After the jump movement, it is discharged from the discharge port, and finally the screening work is completed.

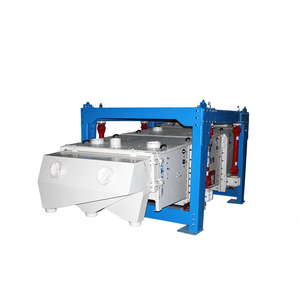

machine, i.e. the screen box, moves back and forth under the action of inertia force, and the screen box drives the screen surface

to oscillate periodically, so that the material on the screen surface can make a directional jump motion with the screen box.

During this period, the material smaller than the screen aperture falls into the lower layer through the screen hole and becomes

the material under the screen, and the material larger than the screen aperture is rolled continuously.

After the jump movement, it is discharged from the discharge port, and finally the screening work is completed.