- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

No

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TONTEN

-

Model Number:

-

LFC-2

-

Product name:

-

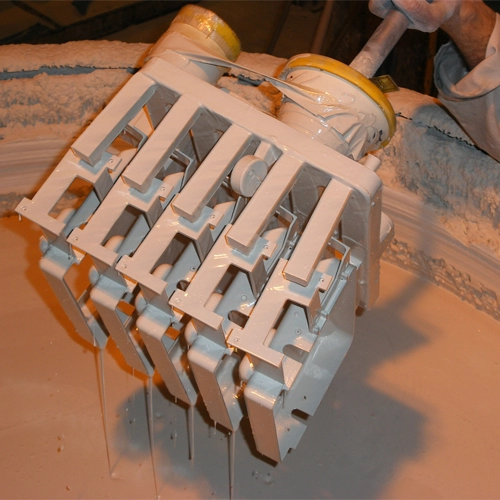

Dry powder aluminum lost foam casting coating EPS Lost foam coating

-

Application:

-

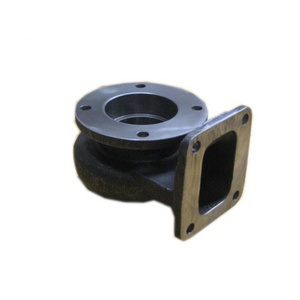

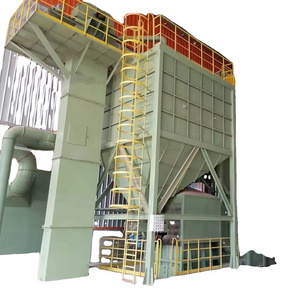

Foundry

-

Surface treatment:

-

Polishing

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

Technology Support

-

Standard:

-

DIN

-

Dimensions:

-

Customized Sizes

-

Tolerance:

-

0.01mm

-

Color:

-

Customized Color

-

Sample:

-

support

Quick Details

-

CAS No.:

-

13463-67-7

-

Other Names:

-

lost foam coating

-

MF:

-

coating

-

EINECS No.:

-

No

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TONTEN

-

Model Number:

-

LFC-2

-

Product name:

-

Dry powder aluminum lost foam casting coating EPS Lost foam coating

-

Application:

-

Foundry

-

Surface treatment:

-

Polishing

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

Technology Support

-

Standard:

-

DIN

-

Dimensions:

-

Customized Sizes

-

Tolerance:

-

0.01mm

-

Color:

-

Customized Color

-

Sample:

-

support

Dry powder aluminum lost foam casting coating EPS Lost foam coating for cylinder heads

Dry powder aluminum lost foam casting coating EPS Lost foam coating for cylinder heads

|

Model

|

Alloy Type

|

Dilution Ratio

|

Density(g/cm³)

|

Suspension Property

|

High Temperature Strength(600℃)kpa

|

High Temperature Permeability(600℃)cm³/gmin

|

|

LFC-1

|

Gray iron

|

1:(0.55-0.65)

|

1.3-1.5

|

≥98%

|

60-65

|

0.68-0.78

|

|

LFC-2

|

Ductile iron

|

1:(0.55-0.65)

|

1.3-1.5

|

≥98%

|

60-65

|

0.68-0.78

|

|

LFC-3

|

High manganese steel

|

1:(0.55-0.65)

|

1.2-1.4

|

≥98%

|

50-60

|

0.68-0.78

|

|

LFC-4

|

Carbon steel/chrome steel

|

1:(0.55-0.65)

|

1.7-1.9

|

≥98%

|

65-68

|

0.6-0.8

|

|

LFC-5

|

Stainless steel/alloy steel

|

1:(0.55-0.65)

|

1.7-1.9

|

≥98%

|

65-68

|

0.6-0.8

|

|

LFC-6

|

Aluminum/brass/copper

|

1:(0.55-0.65)

|

1.2-1.4

|

≥98%

|

50-60

|

0.68-0.78

|

Custom Packaging

Example: Paper bags with wooden bead on pallets.

Other custom packaging or LOGO is also welcomed.

Strong Jumbo Bags

Only provide strong jumbo bags with

plastic inner and Bottom discharge

outlet.

Common 25KG PP Bags

25KG plastic bags is the regular packaging with free charge.

We are specialized in production of Abrasives Material, Refractory Material, Filter Material, Wear Resistance Material, Chemical Products etc. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

1). Abrasive material: Brown fused alumina(BFA), White fused alumina, Garent, Ceramsite foundry sand, Quartz sand, Black silicon carbide, Aluminum oxide, Ceramic sand, Glass Microsphere, Copper Slag, Walnut Shell, Corncob etc.

2). Refractory material: Insulation brick, High alumina brick, refractory brick for pizza ovens , Castable, Bauxite,etc.

3). Filter Material: Quartz sand, Walnut shell, Ceramic grain filters etc.

Al2O3 ≥ 95% or customized

Color: Dark Brown

Mohs Hardness: ≥9.0

True Density: ≥3. 90g/cm3

Bulk Density: 1.53~1.99g/cm3

Al2O3≥99.4%

Color: White

Mohs Hardness: 10.0

True Density: 3.95~4.0g/cm3

Bulk Density: 1.53~1.99g/cm3

Al2O3: 60%~80% or customized

Color: Black

Mohs Hardness: ≥9.0

True Density: ≥3. 50g/cm3

Bulk Density: 1.53~1.99g/cm3

Color: Black

Mohs Hardness: 6-7

True Density: 3. 50g/cm3

Bulk Density: 1.75g/cm3

Color: Red or Dark Red

Appearance: Angular particle

Hardness: 7.0-8.0 Moh

Specific Gravity: 3.9-4.1g/cm3

Color: Transparent

Specific gravity: 2.4-2.6g/cm3

Bulk density: 1.5g/cm3

Moh's Hardness: 6-7 Mohs