In capacitive level measurement, the sensor and container form two electrodes of a capacitor.

The capacitance change caused by positional changes will be transformed into a switching signal.

Using the measured object as the medium, an induction rod is used to detect the electrical

capacity between the induction rod and the barrel wall (ground electrode). When the induction

rod is covered by the material, the electrical capacity increases. When the capacitance matching

value set by the internal circuit of the switch is reached, the circuit generates high-frequency

resonance, detects the resonance signal, and converts it into switch action.

The RCS series products have undergone a brand new circuit design, upgrading analog circuits to

digital intelligent circuits, greatly improving user experience

International operation efficiency enhances the stability of product use, greatly improves

accuracy, and easily adapts to different material characteristics.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

RCS

-

Product name:

-

Water Level Sensor

-

Application:

-

Level Control

-

Material:

-

Stainless Steel

-

Type:

-

RF Module

-

Output signal:

-

Relay

-

Measuring Range:

-

300-15000mm

-

Power supply:

-

220VAC/ 24VDC

-

Operating Temperature:

-

40-80 (Standard Type)

-

Process pressure:

-

0.1~2.0MPa

-

Process connection:

-

Flange Thread

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

shkeqi

-

Model Number:

-

RCS

-

Product name:

-

Water Level Sensor

-

Application:

-

Level Control

-

Material:

-

Stainless Steel

-

Type:

-

RF Module

-

Output signal:

-

Relay

-

Measuring Range:

-

300-15000mm

-

Power supply:

-

220VAC/ 24VDC

-

Operating Temperature:

-

40-80 (Standard Type)

-

Process pressure:

-

0.1~2.0MPa

-

Process connection:

-

Flange Thread

Product Description

operational principle

characteristic

1.Independent of material density, suitable for switch control of various conductive,

non-conductive liquids, and solid particles

2.Can be used in harsh environments such as high pressure, vacuum, high temperature, low

temperature, strong vibration, and strong corrosive liquids

3.Compact size, simple structure, good dynamic performance, high sensitivity, and strong

resolution

4.No movable parts during operation, reliable operation

5.Capacitive level switches are inexpensive, economical, and durable

non-conductive liquids, and solid particles

2.Can be used in harsh environments such as high pressure, vacuum, high temperature, low

temperature, strong vibration, and strong corrosive liquids

3.Compact size, simple structure, good dynamic performance, high sensitivity, and strong

resolution

4.No movable parts during operation, reliable operation

5.Capacitive level switches are inexpensive, economical, and durable

Specification

|

Application

|

Liquid/Solid/Particle

|

|

Measurable Signal

|

High (HLFS) high or Low (LLFS)

low adjustable |

|

Probe material

|

304/316/316L

|

|

Insulating materials

|

FETP

|

|

Process connection

|

Thread G1,1 NPT/

flange/sanitary interface |

|

Process temperature

|

-40~80℃

|

|

Process pressure

|

-1~20Bar

|

|

Output signal

|

Relay

|

|

Power supply

|

20~46VDC/22~265VAC(50/60Hz)

|

|

Power

|

Max.2W

|

|

Sensitivity

|

10PF

|

|

Authentication

|

CE/ATEX/ISO9001

|

|

Protection grade

|

IP65

|

|

Material of junction box

|

Aluminum alloy baking paint/PEEK/stainless steel

|

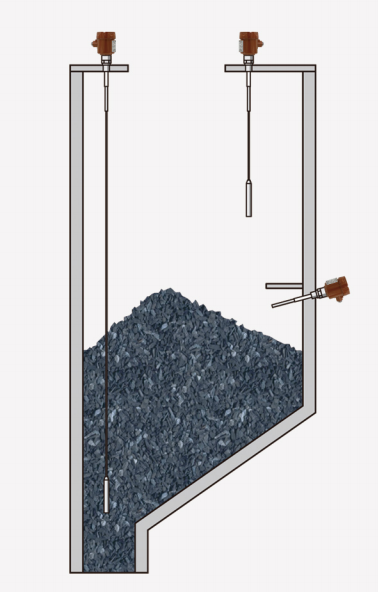

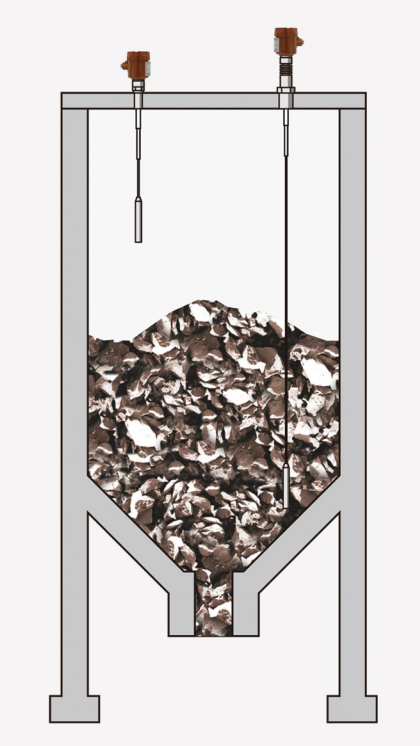

installation diagram

When measuring solid block materials, the steel cable type measuring probe is first selected compared to the rod type measuring probe. Due to the fact that the steel cable type measuring probe can track the movement of solid materials, it can significantly improve the durability of the instrument in abrasive and highly moving solid materials. The switch point is usually located on a heavy hammer, which has high measurement sensitivity due to its large area, especially in media with small dielectric constants. When installing the static capacitance level switch on the side, it should be avoided to be installed near the feeding port to reduce damage to the sensing rod during unloading impact. If the material is large or the RF admittance switch is in the position where the material falls, a protective ceiling should be equipped to avoid mechanical overload. Install a protective shield 200mm above the switch and tilt it slightly (about 20.30 °) to avoid clumping. When measuring heavy materials, the plate type can be selected, but it is important to note that the thickness from the barrel wall to the fixed flange cannot exceed 25mm, otherwise there may be concerns of misoperation of the switch.

According to different working conditions and measuring rod structures, the installation method can be top mounted/side mounted/bottom mounted. When the material is heavy and the switch point distance is far, a steel cable probe can be selected. Typical heavy solid materials include cement, sand, filler, and gravel. When installing the top, it is necessary to consider whether the position of the resting angle can enable the sensing rod to detect the raw material. When installing the steel cable type, attention should be paid to maintaining a minimum distance of 300mm between the sensing rod and the barrel wall. When installing vibrator equipment in the barrel groove or conveying pipeline, it is necessary to consider whether it will damage the internal parts of the switch. Suggest using CS-400 split type.

Flexible steel cable probes can prevent mechanical loads caused by the movement of solid materials. For solid materials with small dielectric constants, it is recommended to install them on the side, as horizontally installed measuring rods can be quickly covered over their entire length, thus having much more reliable switching functions. Therefore, a protective top should be installed above the measuring rod to prevent damage from falling media. If the measuring rod is slightly tilted downwards during installation, it can facilitate the sliding of the deposited solid material. Here, the medium must not be too coarse or too heavy.

Static capacitive level switches are also widely used in liquid measurement. They can be used to prevent overflow and prevent dry operation. The installation position can be from the top, side, or bottom. It should be avoided to install near the feeding port and avoid the flow trajectory of the liquid to reduce interference caused by the discharge impact sensor rod. If the switch must be installed near the feeding port, please install a protective baffle 200mm above the switch. When multiple sensing rods are installed simultaneously, a distance of at least 300mm should be maintained between each switch. If the switch point is far away during top installation, a steel cable probe can be selected, and the switch point is usually located on the heavy hammer. In the case of stirring, a delay of 0-30 seconds can be selected to effectively avoid interference caused by splashing and fluctuations during stirring.

Install the standard type, and the insulation part must extend more than 30mm into the barrel to avoid possible misoperation if there is accumulated material in the connecting pipe. When installing on the side, attention should be paid to the installation position. If the feeding port is not fed from the center, the resting angle a and the corresponding point of the feeding port must be considered for installation, otherwise it is easy for the liquid level switch to not operate. Used as a device to prevent overflow and dry operation in media that are prone to adhesion and conductivity. Due to its mechanical construction with active shielding sections and active measurement peaks, even a few centimeters thick attachment cannot distort the measurement results. Raw materials with poor fluidity can be stacked on top using the upper installation method to reduce the possibility of bridging caused by material accumulation. By using the vertical installation method, bridging phenomena can be eliminated at the process interface.

If the switching points should be as precise as possible, it is recommended to install them on the side, as horizontally installed

measuring rods can be quickly covered throughout their entire length, thus having significantly more reliable switching functions.

The sensing rod should be tilted downwards and maintained at an angle of 20 ° with the horizontal line for optimization, which can

increase sensitivity and reduce damage to the switch caused by cutting impact. When it is necessary to obtain the maximum switch

point as accurately as possible, a partially insulated measuring probe can also be installed, which may experience a short circuit

when reaching the reported level. This allows the measuring probe to switch reliably and replicable.

measuring rods can be quickly covered throughout their entire length, thus having significantly more reliable switching functions.

The sensing rod should be tilted downwards and maintained at an angle of 20 ° with the horizontal line for optimization, which can

increase sensitivity and reduce damage to the switch caused by cutting impact. When it is necessary to obtain the maximum switch

point as accurately as possible, a partially insulated measuring probe can also be installed, which may experience a short circuit

when reaching the reported level. This allows the measuring probe to switch reliably and replicable.

Hot Searches