- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GEMCO

-

Dimension(L*W*H):

-

1860*800*1360mm

-

Briquette shape:

-

Round,oval, pillow, square, heart, etc

-

Suitable for:

-

Mainly used for BBQ,also can be used for industry burning

-

Key Selling Points:

-

High Productivity of Coal Briquette Making Machine

-

Raw material:

-

Charcoal powder, coal powder, mineral powder, iron powder

-

Raw material size:

-

Less than 5mm/customization

-

Diameter of roller:

-

290 mm to 800mm/customization

-

Color:

-

Client's Required

-

Briquette Making Machine Test Report:

-

Provided

Quick Details

-

Weight (KG):

-

560

-

Marketing Type:

-

Factory Direct Sales, Ordinary Product

-

Production Capacity:

-

5.5

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GEMCO

-

Dimension(L*W*H):

-

1860*800*1360mm

-

Briquette shape:

-

Round,oval, pillow, square, heart, etc

-

Suitable for:

-

Mainly used for BBQ,also can be used for industry burning

-

Key Selling Points:

-

High Productivity of Coal Briquette Making Machine

-

Raw material:

-

Charcoal powder, coal powder, mineral powder, iron powder

-

Raw material size:

-

Less than 5mm/customization

-

Diameter of roller:

-

290 mm to 800mm/customization

-

Color:

-

Client's Required

-

Briquette Making Machine Test Report:

-

Provided

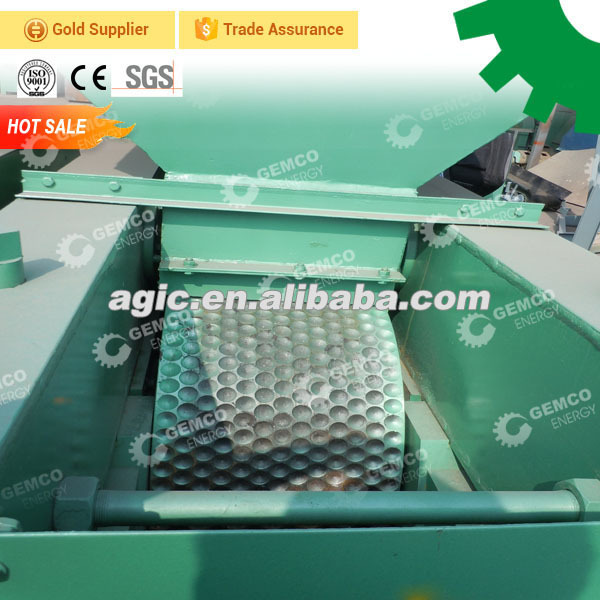

wholesale price coke powder cold charcoal & coal briquette making machine

The

charcoal & coal briquette making machine

is mainly used to press the charcoal dust that is hard to mold, which is characterized by big molding pressure. The

coke powder briquette making machine

can be used for charcoal powder molding, coal molding; powder molding; gypsum molding; coke powder molding and scrap iron molding. This series of

sawdust coke powder briquette making machine

can be used to make charcoal briquettes of different shapes.

GCXM-1 charcoal & coal briquette making machine

Parameters of GCXM-1 coke powder briquette making machine

| Model | GCXM-1 |

| Power | 5.5kw |

| Capacity | 1-2TPH |

| Diameter of Roller | 290mm |

| Form of Structure | 200mm |

| Overall Size | Two rollers single press |

| Weight | 560kg |

Click Now for Catalogs & Factory Price !

GEMCO charcoal & coal briquette making machine

GEMCO charcoal & coal briquette making machine is also called roll press coke powder briquette making machine which have been used to increase the particle size of and bulk densities of materials to improve their handling. In a roll press briquetter, material is densified by compression between two main counter-rotating rolls. The roll surfaces have pockets to form briquettes of desired size and shape when the material passes between the rolls. GEMCO factory price small biomass coke powder briquette making machine can give you a bright future in your business.

Click Now for Catalogs & Factory Price !

Material & final briquettes of coke powder briquette making machine

Raw material used in sawdust coke powder briquette making machine

Raw material can be processed by coke powder briquette making machine: Coal dust like brown coal, lignite coal, lean coal, anthracite, peat, and the old brown coal, charcoal fines, coke dust/fines, peacoke, carbon black, carbon dust, clay, activated carbon, etc.

In order to ensure the good quality and mechanical strength of the final product, special care should be taken to ensure that the granule size fed to the machine is maintained below 3mm, preferably in the range of 30-40% smaller than 1–2 mm, with no more than 10% over 2 mm.

The moisture content of the mixture has also a critical effect on the quality of the final product, so it should be kept in the range of 8-10%.

Final briquettes produced by charcoal & coal briquette making machine

The coal dust briquette charcoal machine is also called roll press briquette charcoal machine which can supply higher pressure and higher intensity during production of briquettes; it’s mainly used in the briquettes making of various color and black metallic mine powder. It can be used to make briquettes from coal powder, charcoal powder and coke powder with binder.

This type of

coke powder briquette making machine

have two larger rollers in a fixed position in the frame, the other two smaller rollers are moveable. As its named implied, it has four rollers and press briquettes for twice times, so it make briquettes stronger and in proper density. Meanwhile, it is easy for combustion, no smell and last longer when burning.

Click Now for Catalogs & Factory Price !

Advantages of charcoal & coal briquette making machine

Click Now for Catalogs & Factory Price !

Our projects

We have a lot of projects overseas, and also get more feedback from our charcoal & coal briquette making machine customers. These projects has been working for more than three years, different local projects seperatly from US, Russia, South africa, Asia, Britain and so on.

Click Now for Catalogs & Factory Price !

Packing & Shipment

FAQ

Click Now for Catalogs & Factory Price !

Certification in charcoal & coal briquette making machine

Our customers