- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

10 T

-

Power (kW):

-

800

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

AE

-

Voltage:

-

380

-

Weight (T):

-

10 T

-

Power (kW):

-

800

Product Description

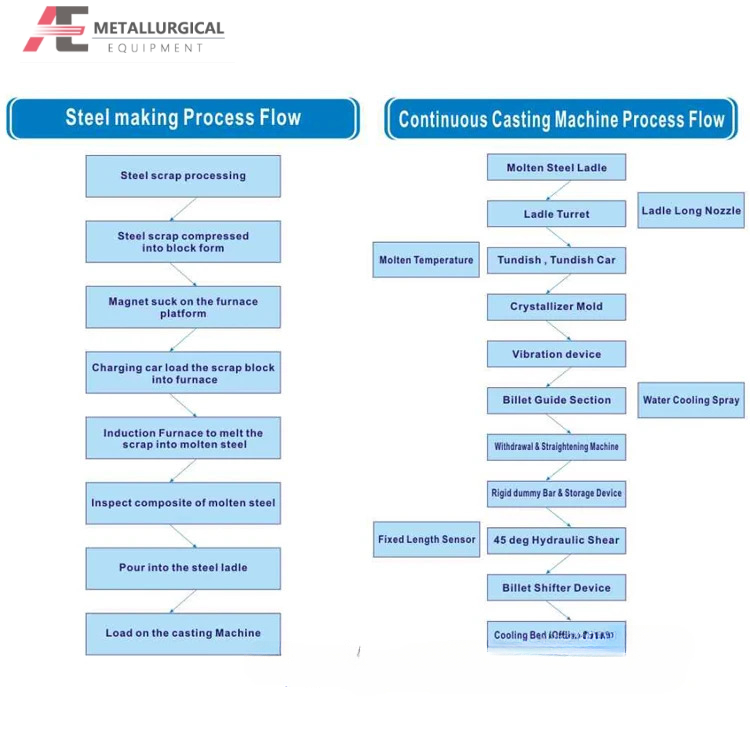

Type of caster Full arc type Continuous casting machine

Radius of the arc (m) R4-8m

Distance between strands (mm) 1250

Number of strand 1-10Strands

Cross section of billet (mm) 80*80-200*200mm

Length of billet (m) 3-12m

Casting steel grade : Normal carbon steel, low allow steel, bearing steel

Casting speed m/min 0-3.5

Dummy bar sending speed m/min 0.5 - 4

Dummy bar type Rigid dummy bar

Casting way Sliding nozzle - Immersion long nozzle - Protection slag

Billet cutting method Flame cutting machine

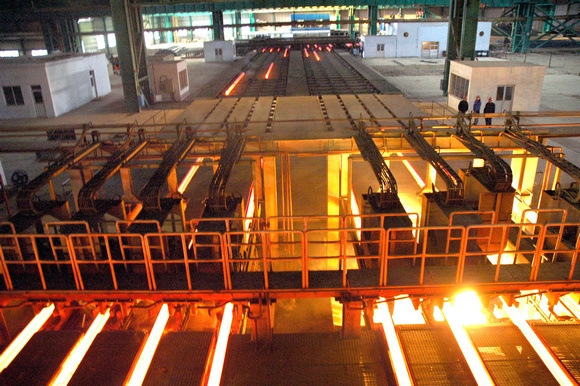

Billet out going mode Terminal roller table - chain type removing machine -sliding rails cooling bed

total length of the caster (m) about 40

Description:

Dummy bar is used in continuous casting machine. It is used to guide the billet.

Application:

The dummy bar is used to tract and lead the cooled and solidified strand and put it out by

the withdrawal and straightening machine.

Features:

In order to avoid the deformation of dummy bar body due to heating,

the dummy bar is equipped with a cooling water pipe inside the bar body. It has the features of smaller deformation, long service life, simple structure and installation, easy operation and maintenance.

Specification:

1. CCM machine parts

2. Diversified arc radius

3. Diversified strands

4. More operations for CCM machine

Technical Parameter:

|

Outer bow radius of bar body |

R3000mm,R4000mm, R5250mm,R6000mm, R7000mm, R8000mm,R10000mm |

|

Section dimension of bar body |

80x80mm,100x100mm,120x120mm,150x150mm,160x160mm,180x180mm,200x200mm |

About Us

With more than 20 years of rich experience, manufacturer in the field of metallurgical machinery equipment, from design, manufacturing to marketing. We have hundreds of successful cases in designing and producing the whole set of equipment, such as Electric Arc Furnace (EAF), Ladle Refining Furnace (LF), Submerged Arc Furnace (SAF), Argon Oxygen Decarburizing Furnace (AOD), Basic Oxygen Furnace (BOF), White Fused Alumina Furnace, Brown Fused Alumina Furnace and CCM Hot Rolling Mill etc.

Exhibition pictures

Booth of International Metallurgical Trade Fair with Congresses Dusseldorf, Germany

Performance cases

Electric arc furnace installation site in South Africa project

Mongolia annual output of 600,000 tons of steel EPC project

Indonesia Ferronickel 25500KVA submerged arc furnace smelting project