The working principle of the walnut sheller:

This machine is mainly used for shelling and taking kernels of dried walnuts. It can flexibly adjust the gap of the inner conical barrel according to the variety and size of walnuts, so as to achieve the shelling effect. The machine feeds the material from the upper hopper, and goes through two mutually cooperating rotating conical barrels for shelling, so that the kernel and the shell are fully separated, so as to facilitate manual sorting and improve work efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

200-300kg/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

OSKI

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

900*700*1400MM

-

Weight:

-

210 KG

-

Keyword:

-

walnut sheller machine

-

Kw:

-

Automatic Small Walnut Shelling Machine

-

Key words:

-

walnut kernel peeling machine

-

Shelling rate:

-

98%

-

Raw material:

-

stainless steel

-

Capacity:

-

200kg per hour

-

Local Service Location:

-

None

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Online support

-

Function:

-

break the walnut and separate the shell

Quick Details

-

Marketing Type:

-

New Product 2022

-

Type:

-

Food Machinery

-

Use:

-

Sheller

-

Production Capacity:

-

200-300kg/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

OSKI

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

900*700*1400MM

-

Weight:

-

210 KG

-

Keyword:

-

walnut sheller machine

-

Kw:

-

Automatic Small Walnut Shelling Machine

-

Key words:

-

walnut kernel peeling machine

-

Shelling rate:

-

98%

-

Raw material:

-

stainless steel

-

Capacity:

-

200kg per hour

-

Local Service Location:

-

None

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Online support

-

Function:

-

break the walnut and separate the shell

Product Description

Automatic Pecan Shelling Machine Kernel Separating Machine Walnut Dehuller Sheller Hard Walnut Shelling Machine

Product performance characteristics

:

1

. This walnut shell breaking machine is the second generation product developed by our company, which is 40~50 times of artificial walnut shell breaking.

2

. The walnut shelling machine is light in weight (220KG), small in size, easy to transport, simple in operation, flexible in use, and highly efficient in breaking shells, and can be operated by ordinary personnel.

3

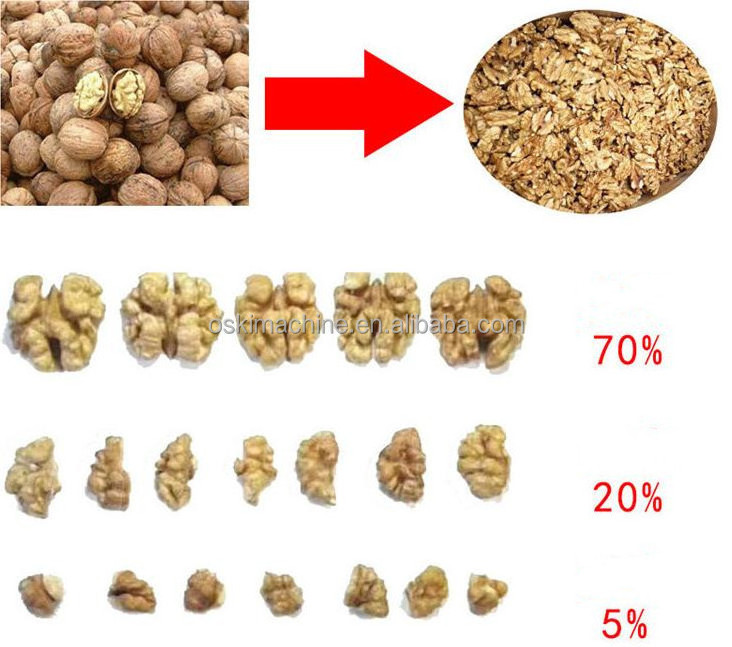

. The walnut shell breaking rate of the graded walnuts entering the walnut shell breaking machine is higher than 98%, and the breakage rate of walnut kernels is less than 5%.

4

. It is suitable for small walnut processing enterprises and walnut processing operators with a daily processing capacity of 4-5 tons.

5

. The gap between the shell-breaking rollers can be adjusted, and the gap can be adjusted from 15 to 40mm. After the gap is adjusted, the whole kernel can be peeled off.

6

. This machine adopts 220V lighting electricity (or 380V power electricity), with a power of 1.1KW, which is energy-saving and power-saving.

Specification

|

model

|

SK-HT900

|

|

Specification

|

900*700*1400MM

|

|

efficiency

|

200-250KG/H

|

|

Voltage

|

2.2V

|

|

weight

|

210KG

|

|

removal rate

|

80%

|

Details lmages

Instructions

:

1.

Check whether the connection and transmission parts are loose and whether there is any abnormal phenomenon.

2.

Whether the power supply and electrical device terminals are in good contact.

3.

The roller gap has been adjusted before leaving the factory. Due to the different sizes of walnuts, the gap is adjusted according to the size of the fruit shape.

4.

Gap adjustment

:

Small is: Loosen the lower bolt of the pulley, rotate the nut on the top of the central shaft, adjust the gap upwards to increase the larger the broken shell, and decrease the downward gap to make the broken shell smaller, and then re-fix the bolts after adjustment. Large is: control the speed of speed, the faster the speed, the smaller the shell will be broken, and the slower the speed, the larger the shell will be broken.

5.

Due to the different shell thickness of different walnut varieties, put in a small amount of walnuts before starting the machine to see the shelling effect. By adjusting the size or speed of the roller gap, the high integrity rate of kernels after shell breaking can be achieved. After the small fruit is not shelled, readjust the gap and then peel it off.

6.

Pay attention to oil filling when the geared motor is used, and check and fasten all transmission parts in time for normal use.

Structure of walnut sheller:

The walnut sheller is composed of frame, rotor, motor, fan, screen, feeding hopper, V-belt pulley and its transmission V-belt. After the machine is running normally, put the walnuts into the feeding hopper evenly and continuously, the walnuts are broken under the repeated blows, frictions and collisions of the rotor, and the walnuts and Under the rotating wind pressure and blow of the rotor, the broken shell is separated from the large-hole screen through a screen with a certain aperture, and the small peeled fruit after screening is replaced with a small-hole screen. Secondary peeling, filtration and separation. Under the action of the blowing force of the rotating fan, the walnut shells and walnuts make the light-weight shells blow out of the body, and the heavier fruits are blown out of the body by vibration. Screening to achieve the purpose of cleaning

Packing & Delivery

Why Choose Us

|

Package

|

Machine will be packed in wooden case to make sure the machine is in perfect condition when you receive it.

|

|

Document

|

Professional team make the best shipping plan to save time and costs. We'll send you documents, like BL, PL, Invoice, CO etc.

|

|

After shipment

|

We have professional transportation team to make the best shipping plan for you, saving time and costs. After sail, we will send you all documents, like Bill of Loading, Packing list, Invoice, Certificate of Original.

|

|

After receiving

|

Normally the machines are already installed before delivery, after you receiving it, you can directly connect to the power supply and use it. We may also send you the manual and operating video to show you how to use it.

|

|

After-sales service

|

Received the machine,please feel free to contact us if you have any problem,we will solve the problem online at any time

|

Company&Certifications

Welcome to Zhengzhou Oski Machinery Co., Ltd.

Zhengzhou Oski Machinery Co., Ltd. is a factory with many years of production experience and good raw material supply, so the price is very competitive; In addition, all raw materials are 100% new, ensuring the overall quality and service life of the machine. Test the machine before leaving the factory to ensure the normal operation of the machine. Send spare parts to you for replacement to reduce the international transportation cost of customers later.

Workshop

FAQ

|

MOQ

|

Minimum order quantity is 1 set, More quantity more discount.

|

|

Machine Voltage

|

We can customize the voltage as your request. Like 110v/220v/380v/415v, 1 or 3 phases.

|

|

Payment methods

|

Alibaba online order, T/T bank transfer, WeChat, Alipay, L/C, etc.

|

|

Warranty time

|

Our warranty time is 2 years. Free spare parts within 2 years. After warranty, we still supply online after-sales service.

|

|

Production time

|

The machine is generally in stock, the production time is about 3-7 days, and the transportation will be arranged for you as soon as possible.

|

|

Machine quality

|

All machines are brand new, and the quality of the machines is our top priority. Before leaving the factory, we will test the machines to ensure that they can work normally.

|

Contact Us

Hot Searches