- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YECI

-

Model Number:

-

N35-N52

-

Product Name:

-

disc permanent rare earth powerful D12x2 custom neodymium magnets

-

Material:

-

Neodymium

-

Magnet shape:

-

Disc

-

Size:

-

D10 x 2 or customize

-

Coating:

-

NiCuNi

-

Magnetism direction:

-

Axially Magnetized

-

Strength:

-

approx. 1.8 kg

Quick Details

-

Tolerance:

-

±5%, +/-0.05mm

-

Grade:

-

Neodymium Magnet, N52

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

YECI

-

Model Number:

-

N35-N52

-

Product Name:

-

disc permanent rare earth powerful D12x2 custom neodymium magnets

-

Material:

-

Neodymium

-

Magnet shape:

-

Disc

-

Size:

-

D10 x 2 or customize

-

Coating:

-

NiCuNi

-

Magnetism direction:

-

Axially Magnetized

-

Strength:

-

approx. 1.8 kg

Product Description

|

Product Features

|

|

|

|

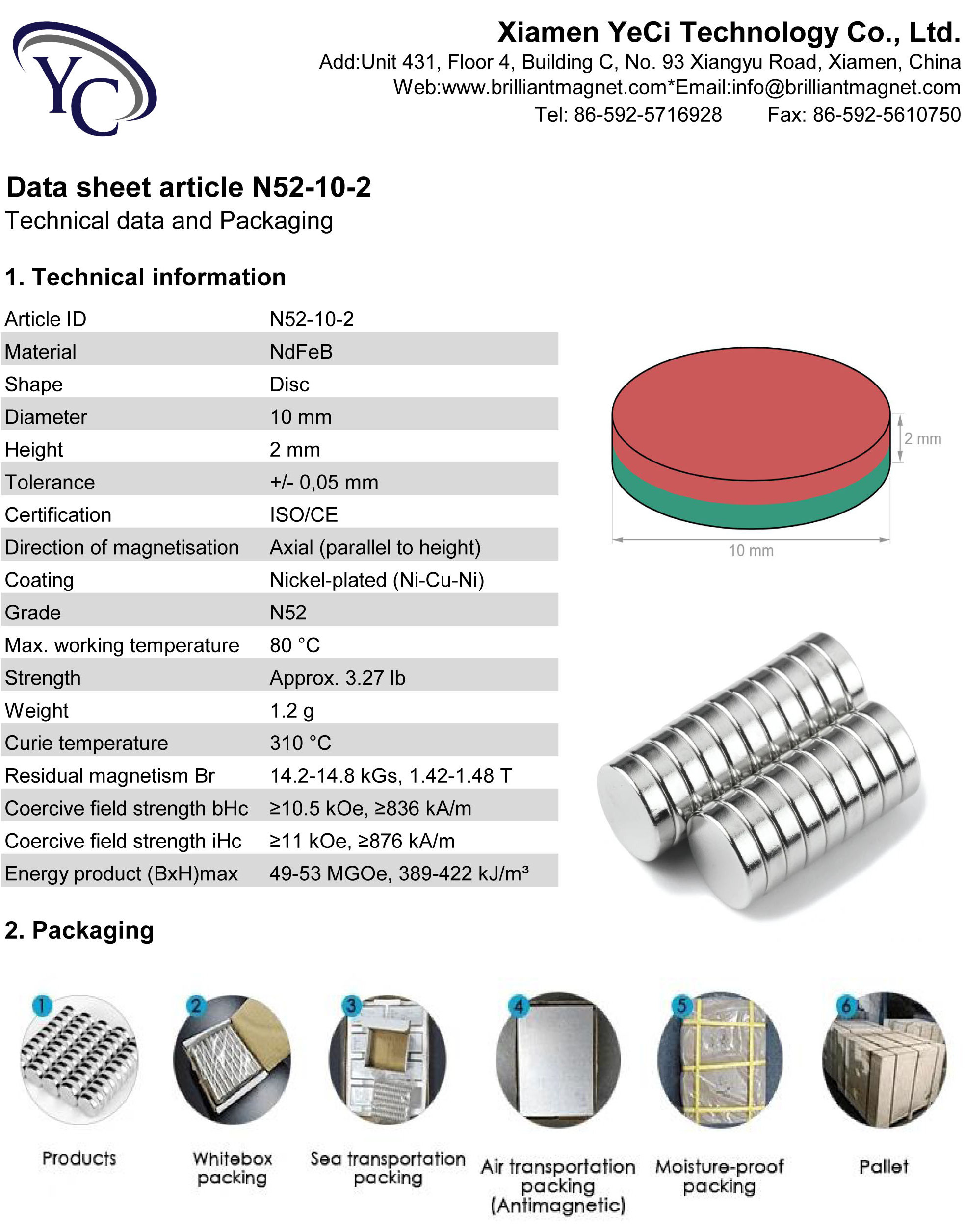

Product Name

|

Bar/disc permanent powerful D10x2 custom neodymium magnets N35 ~N52

|

|

|

Material

|

Neodymium Magnet

|

|

|

Size

|

D10x2 Or Customized size

|

|

|

Coating

|

Ni-Cu-Ni,(Zn,Ni-Cu-Ni,Ni,Gold, Silver, Copper, Epoxy, Chrome, etc)

|

|

|

Grade

|

N52/Customized (N28-N52; 30M-52M;15H-50H;27SH-48SH;28UH-42UH)

|

|

|

Magnetic Direction

|

Axially, Diametrally , Thickness ,Multi-poles magnetized

|

|

|

Packaging

|

Paper Box

|

|

|

Weight

|

1.2 g

|

|

Products Details

1. Neodymium Material

Neodymium magnet, also known as NdFeB magnet, is a tetragonal crystal system formed by Neodymium, iron and boron (Nd2Fe14B).

2. High Precision

The tolerances of Yeci magnets can be controlled with ±0.05mm

3. Magnet Plating

Neodymium magnet is mainly composed with Nd-Pr, if the magnet is not electroplated, it will rusted and corroded easily when the

magnet is under moist air environment.

magnet is under moist air environment.

4. Magnetic Direction

The magnet will display or release some of its conserved energy when pulling towards or attaching to something then conserve or

store the energy that the user exerts when pulling it off.

Every magnet has a north seeking and a south seeking face on opposite ends. The north face of one magnet will always be attracted

towards the south face of another magnet.

store the energy that the user exerts when pulling it off.

Every magnet has a north seeking and a south seeking face on opposite ends. The north face of one magnet will always be attracted

towards the south face of another magnet.

Buyer Reviews

Company Introduction

Yeci has 30,000M2 workshop buildings with best-in-class production and inspection instruments, which can control the tolerance of products within 0.03 mm or even more. Our annually production is around 2,000 tons high-performance and high-quality NdFeB magnets, ferritemagnets, flexible rubber magnets, injection magnets etc.. Our products are widely used in types of wind turbines,speakers,earphones and motors, microphones, sensors, medical care, packaging, sports equipment, crafts and aviation fields.

Production Flow

How Sintered Neodymium Magnets are Made

1. Prepare Materials for the Reaction

The basic compound for most Neodymium magnets is Nd2Fe14B. In practice, the actual chemical reaction used can be more complicated.

2. Melting

The products are heated by creating electrical eddy currents through it, all in a vacuum to keep contaminants out of the reaction.

3. Milling

Jet milling turns the resulting material into a powder with a very small particle size. The average particle size is on the order of 3 micrometers.

4. Pressing

The powder is pressed together to form a solid that has a preferred magnetization direction.

5. Sintering

Sintering is a common process in powder metallurgy. The material is compressed at elevated temperatures (as high as 1080°C) below the material's melting point, until its particles adhere to each other.

6. Machining

The sintered magnets are cut to the desired shape using a grinding process.

7. Plating

The individual magnets are electroplated with three layers: nickel, copper and nickel.

8. Magnetization

They are placed in a fixture that will expose the magnet to a very strong magnetic field for a brief moment.

9. Inspection

The quality of the resulting magnets is inspected for a variety of properties. A digital measuring projector verifies the

dimensions.

The basic compound for most Neodymium magnets is Nd2Fe14B. In practice, the actual chemical reaction used can be more complicated.

2. Melting

The products are heated by creating electrical eddy currents through it, all in a vacuum to keep contaminants out of the reaction.

3. Milling

Jet milling turns the resulting material into a powder with a very small particle size. The average particle size is on the order of 3 micrometers.

4. Pressing

The powder is pressed together to form a solid that has a preferred magnetization direction.

5. Sintering

Sintering is a common process in powder metallurgy. The material is compressed at elevated temperatures (as high as 1080°C) below the material's melting point, until its particles adhere to each other.

6. Machining

The sintered magnets are cut to the desired shape using a grinding process.

7. Plating

The individual magnets are electroplated with three layers: nickel, copper and nickel.

8. Magnetization

They are placed in a fixture that will expose the magnet to a very strong magnetic field for a brief moment.

9. Inspection

The quality of the resulting magnets is inspected for a variety of properties. A digital measuring projector verifies the

dimensions.

Related Products

Product packaging

FAQ

Q: Are you trading company or manufacturer ?

A: We are a professional manufacturer of neodymium magnets more than 20 years

Q: How long is your delivery time?

A:Sample needs 3-5 days, mass production time needs 1 week

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge if we have magnet stock.

Q: What is your terms of payment ?

Payment<=3000USD, 100% in advance. Payment>=3000USD, 30% T/T in advance ,balance before shippment.

Q: What format of the file do you need if I want my own design?

AI,CDR,PDF OR JPEG etc.

A: We are a professional manufacturer of neodymium magnets more than 20 years

Q: How long is your delivery time?

A:Sample needs 3-5 days, mass production time needs 1 week

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge if we have magnet stock.

Q: What is your terms of payment ?

Payment<=3000USD, 100% in advance. Payment>=3000USD, 30% T/T in advance ,balance before shippment.

Q: What format of the file do you need if I want my own design?

AI,CDR,PDF OR JPEG etc.

Hot Searches