- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Suhang

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7*1.5*1.2m

-

Weight:

-

10000 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Advantage:

-

Excellent performance

-

Feature:

-

Easy operation

-

Material width:

-

100-600mm

-

Spare parts:

-

Imported brands

-

Control system:

-

PLC with touch screen

-

Roller material:

-

Gcr15

-

Material of cutting:

-

Cr12mov with quench HRC58-62°

-

Color:

-

Blue or customized

-

Main frame:

-

H 350 steel

Quick Details

-

Type:

-

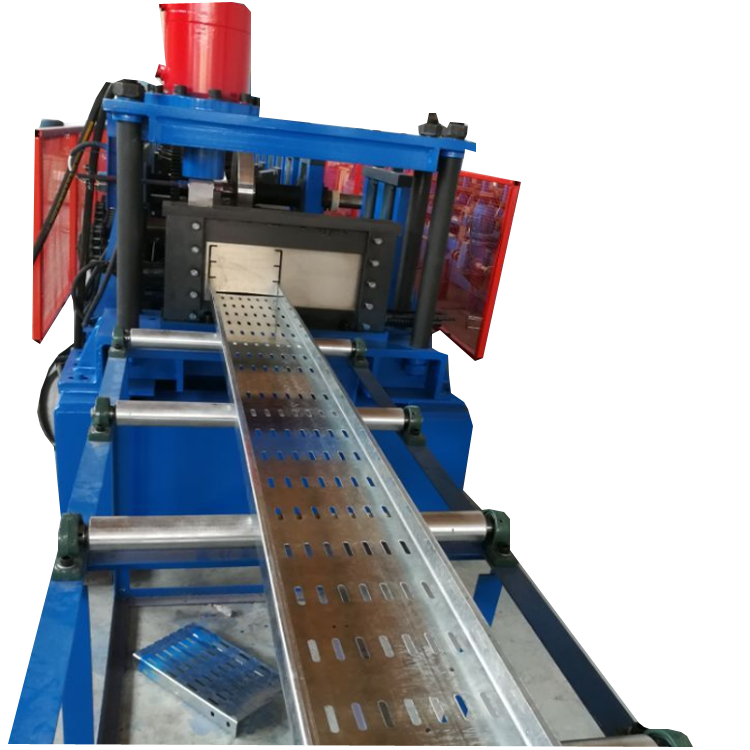

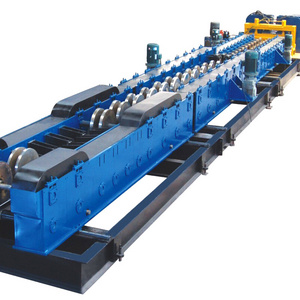

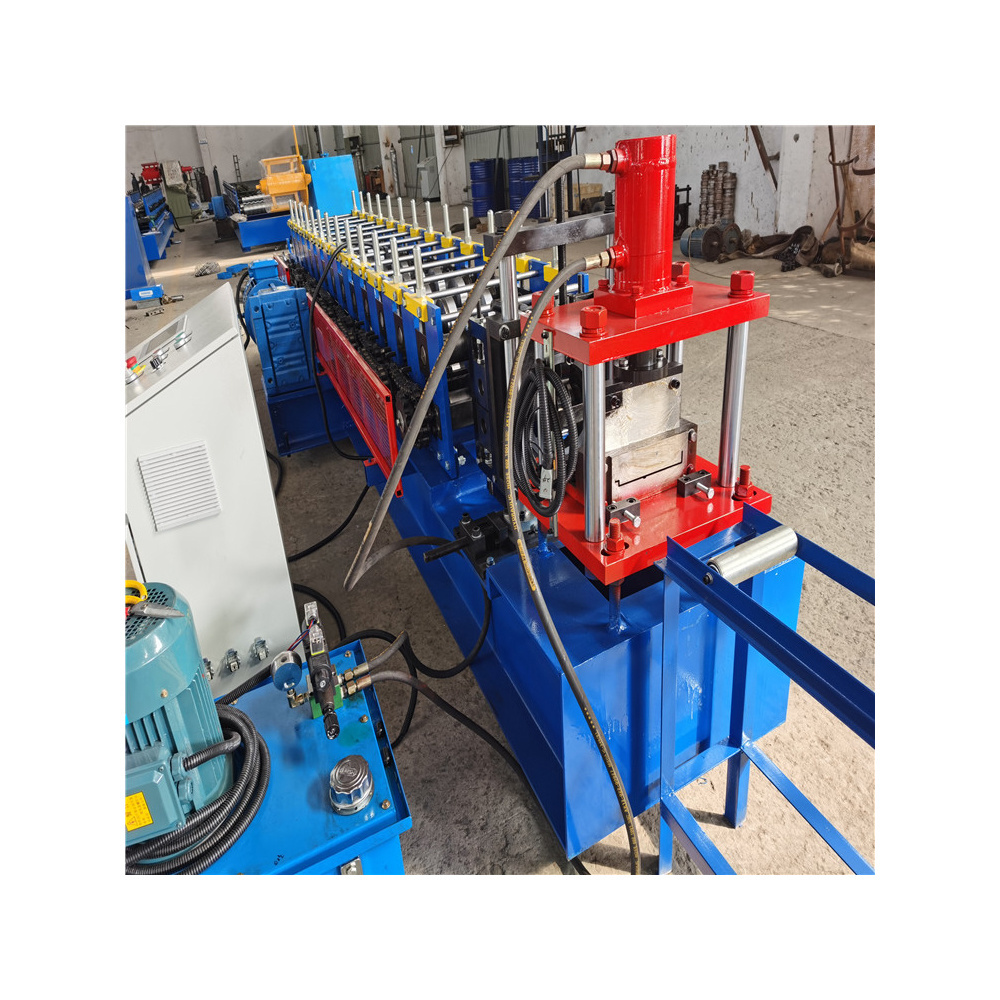

ladder cable tray roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

6-12m/min

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Suhang

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7*1.5*1.2m

-

Weight:

-

10000 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Advantage:

-

Excellent performance

-

Feature:

-

Easy operation

-

Material width:

-

100-600mm

-

Spare parts:

-

Imported brands

-

Control system:

-

PLC with touch screen

-

Roller material:

-

Gcr15

-

Material of cutting:

-

Cr12mov with quench HRC58-62°

-

Color:

-

Blue or customized

-

Main frame:

-

H 350 steel

|

speed

|

6-12m/min

|

|

driving method

|

by chain

|

|

working process

|

decoiling--guiding&roll forming--hydraulic cutting--products collecting

|

|

machine size

|

7*1.5*1.2m

|

|

machine weight

|

6 ton

|

|

electrical configuration

|

first-line brands

|

|

advantage

|

full automatic; high stability; easy operation

|

1.Does one machine can only produce one size?

Not exactly, it depends on the machine.

2.Do you have after sales support?

Yes,we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3. You are trade company or factory?

We are Manufacturer.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be made out with 40 working days.If you need machines in hurry, we

can make it for you less than a month.

5. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide.Our engineers can offer the best

professional solution to our worldwide clients.Meanwhile we can provide door-to-door service.

6.How to visit your factory?

By high speed train from Shanghai to Wuxi, half an hour.

7.What's the warranty period?

12 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the

Buyer’s Installation site.

8.May we visit your factory?

Sure,Warmly welcome to our factory at any time.

Not exactly, it depends on the machine.

2.Do you have after sales support?

Yes,we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3. You are trade company or factory?

We are Manufacturer.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be made out with 40 working days.If you need machines in hurry, we

can make it for you less than a month.

5. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide.Our engineers can offer the best

professional solution to our worldwide clients.Meanwhile we can provide door-to-door service.

6.How to visit your factory?

By high speed train from Shanghai to Wuxi, half an hour.

7.What's the warranty period?

12 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the

Buyer’s Installation site.

8.May we visit your factory?

Sure,Warmly welcome to our factory at any time.

Hot Searches