- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Online support

-

type:

-

roll forming machine

-

color:

-

blue

-

Incoming material:

-

Hot-rolled carbon steel

-

Thickness of incoming material:

-

1.5-2.0mm

-

Production Thickness:

-

1.5-2.0mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LMS

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Online support

-

type:

-

roll forming machine

-

color:

-

blue

-

Incoming material:

-

Hot-rolled carbon steel

-

Thickness of incoming material:

-

1.5-2.0mm

-

Production Thickness:

-

1.5-2.0mm

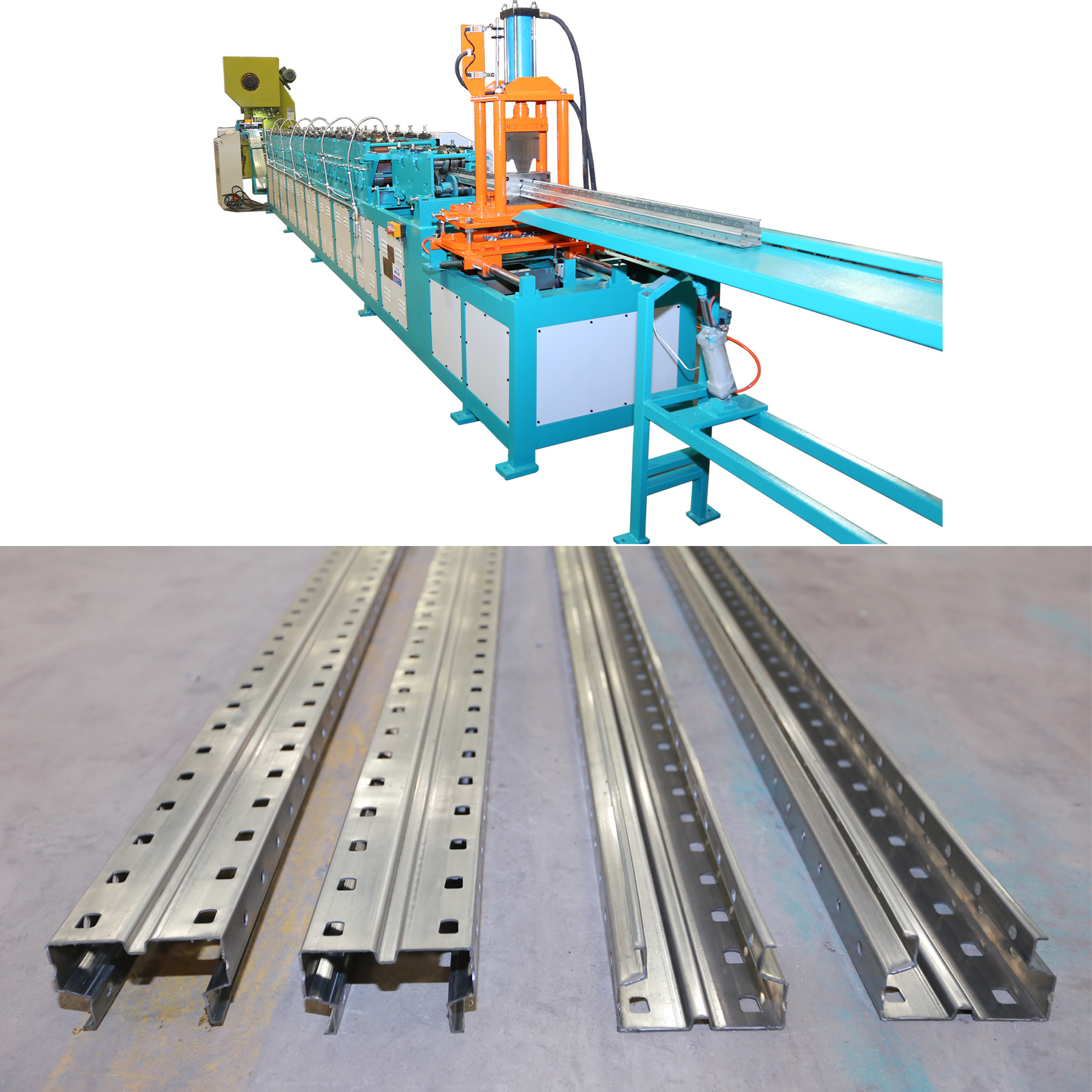

Universal Server Rack / Network Cabinet / Server Cabinet Pillar roll forming machine

LMS is always dedicated to providing high quality China-made machinery at competitive price with ensuring first-class after-sale service to all the customers from home and abroad. Our main products cover roll forming machine, metal sheet machine,

pipe making machine, duct machine, slitting machine, shearing machine, bending machine , drawing machine ,etc.

. A team of experienced engineers is working with PROE design software system and skilled technicians for machine production and inspection. LMS achieves ISO 9001 Quality Management Systems Certificate and enjoys high reputation in domestic and overseas markets.

This metal roll forming machine:

1. LMS Roll Forming is designed one profile for one machine, width-adjustable for various specification.

2 Hole-Punching solution is available, customized according to clients' requirement.

3. Production process: decoiling - (hole-punching) - roll forming - hydraulic cutting-off -PLC controlling

4. Customized drawing or sample quotation is welcome!

Suitable material:

----Incoming material: Hot-rolled carbon steel

Coil ASTM A570 G50 or semi hard.

----Thickness of incoming material: 1.5-2.0mm

----Product width: 90mm and 120mm (adjustable)

----Product height: 68mm

----Drawing of profile: please refer the attached drawing.

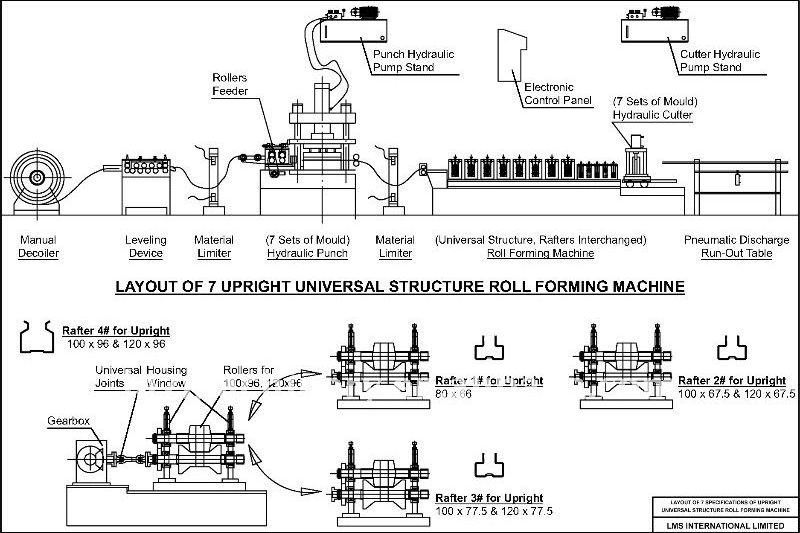

Main parameters of the rack roll forming machine:

Manual Decoiler of the rack roll forming machine

----Hand operated type

----Max outer diameter of coil: 1400mm.

----Inner diameter of coil: 450-520mm.

----Capacity: 2000kgs

----No power to drive

Straightening machine 1 set of the rack roll forming machine

----Incoming material width: 350mm

----Rollers: 11Nos

----Material of roller: GCr15 steel

----Surface hardness of roller: HRC 55-57

----Main motor3:kw

----Rollforming speed: 8M/min

----Method of transmission: chain and gear

Machinery feeding device of the rack roll forming machine

----Incoming material width: 350mm

----Incoming material length each time: within100mm

80 tons power press of the rack roll forming machine

---- Working pressure: 80T

-----stroke4:0times/Min----Equipped with hole punching mould 1 set

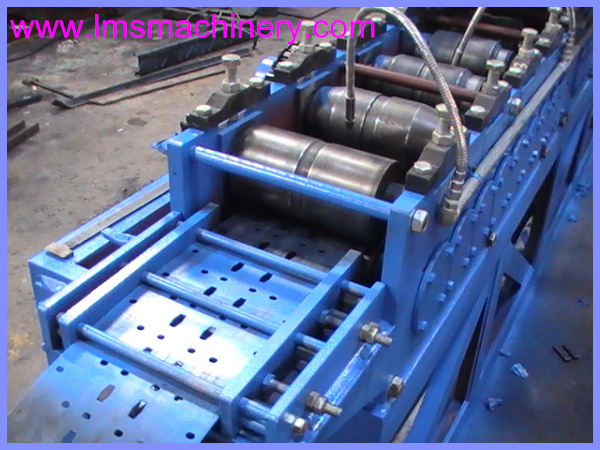

roll forming machine

----Roll forming station:20 Nos

----Material of roller: GCr15 steel

----Surface hardness of roller::HRC 55-57

----Diameter of roller shaft: 55mm, material: 45#steel

----Model of bearing: 60310

----Method of transmission:chain and gear

----Main motor: 15kw, 400 speed reducer

----Roll forming speed: 2--6M/Min

----Equipped with cooling-water pump device

Cutting –off device

----Oil station

----Oil station motor: 4kw

----cutting mould 1 set

----Material of cutting mould Gr12 steel

----Surface hardness of roller: HRC 60-62

----Cutting-off working pressure: 20T

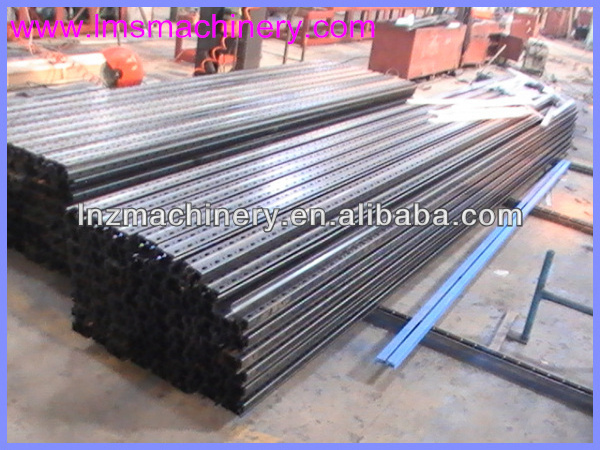

Material output table of the rack roll forming machine

----Table length:6M

---- Precision welding by angle iron

----apply to air unloading

Electronic parts of the rack roll forming machine

----Transducer made in Japan, PLC and man-machine menu

----Voltage:380V.50HZ