- Product Details

- {{item.text}}

Quick Details

-

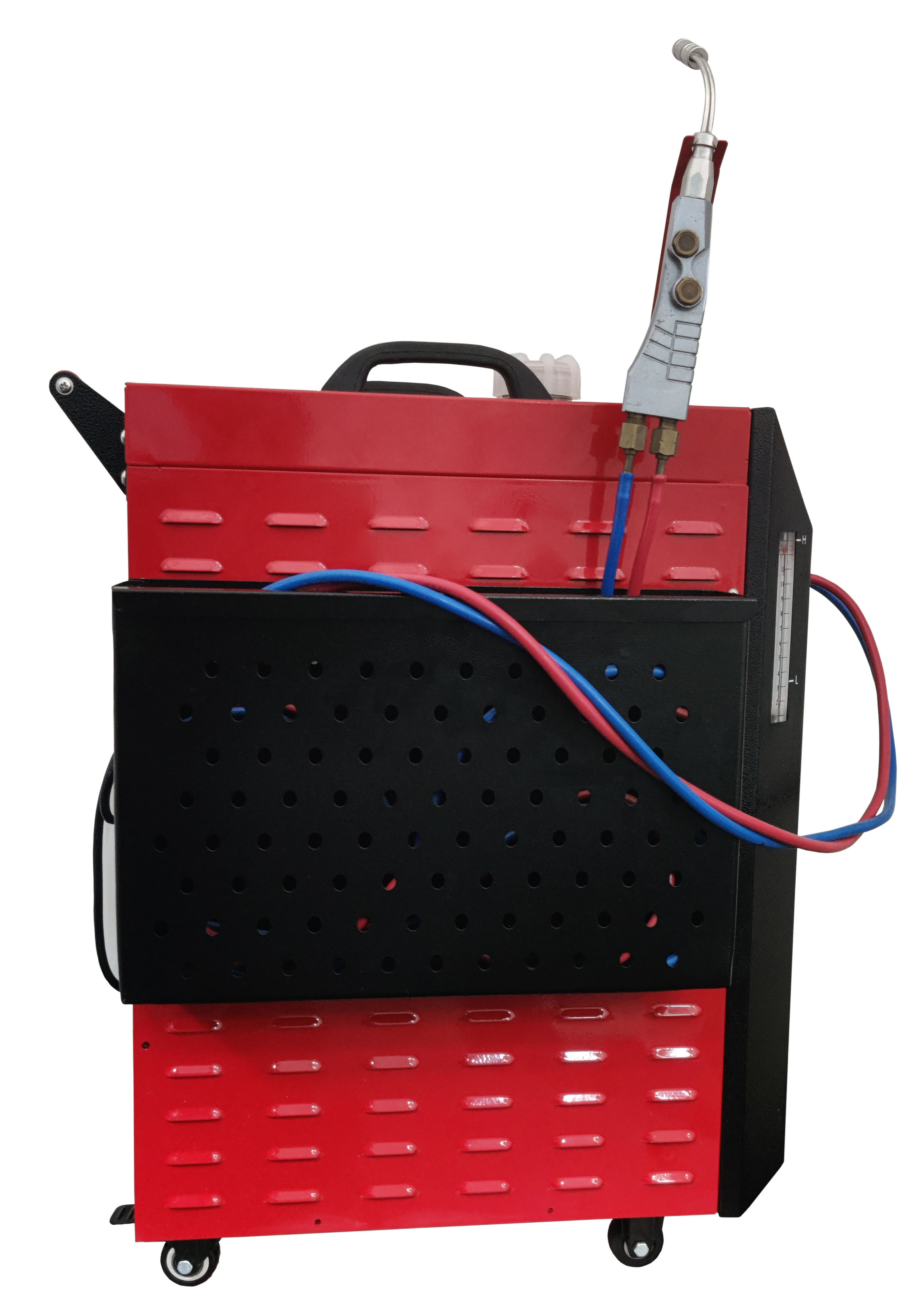

Weight (KG):

-

35

-

Voltage:

-

220V

-

Dimensions:

-

57 *39 * 55

-

Usage:

-

Welding

-

Product name:

-

Hydrogen Brazing Machine

-

Application:

-

Welding Repair Machine

-

Model:

-

SF-2000

-

Flow Rate:

-

2L/min

-

H2 Output:

-

2L/min

-

O2 Output:

-

1L/min

-

Power Supply:

-

220V, 50Hz

-

Max Power Consumption:

-

700w

-

Water Tank Capacity:

-

8L

-

Water Consumption:

-

120ml/min

Quick Details

-

Core Components:

-

PEM Cell

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Green

-

Weight (KG):

-

35

-

Voltage:

-

220V

-

Dimensions:

-

57 *39 * 55

-

Usage:

-

Welding

-

Product name:

-

Hydrogen Brazing Machine

-

Application:

-

Welding Repair Machine

-

Model:

-

SF-2000

-

Flow Rate:

-

2L/min

-

H2 Output:

-

2L/min

-

O2 Output:

-

1L/min

-

Power Supply:

-

220V, 50Hz

-

Max Power Consumption:

-

700w

-

Water Tank Capacity:

-

8L

-

Water Consumption:

-

120ml/min

Safeflame Hydrogen Brazing Machine was designed and manufactured on the base of Sino-British Cooperation and launched into market in 2019.

What ’ s NEW?

NEW Safeflame torch design producing a new “ FLAME ” (Very different from the traditional gas/air or gas/oxy FLAMES)

Safeflame® torches linked to ELECTROLYSERS with SEPARATE streams of HYDROGEN and OXYGEN gases. Dominant “ Joining process ” is FLAME BRAZING.

Why is it SAFER?

NO premixed gases,

NO gas cylinders,

NO light back,

NO corrosive chemicals.

From WATER

This “ new ” safeflame compliments rather than competes with existing commercially available flame. It ’ s a “ new ” additional flame now available to the market.

NOT to be confused with flames from electrolysis of water (mixed gas) which uses corrosive chemicals.

Fuel Gases for Flames

Where & who do we get existing fuel gases from ...

WHY has hydrogen generally been the last choice for fuel gas ?

* Low CV (Calorific Value) 330btu/cf, Natural Gas 1000btu/cf, propane 2500 btu/cf, Acetylene 1300 btu/cf

* Perceived safety issues, particularly with Oxygen and light back

* Safety issues with chemicals from existing HHO flames from water (mixed gases)

* Inconvenience of supply from cylinders for both hydrogen and oxygen

* Lack of real knowledge and experience in the supply chain compared to other fuel gases.

Requirements for combustion: Gas + Oxygen = FLAME

Why choose Hydrogen and Oxgen now ?

* Recent developments with Electrolysis (separate gases) have reduced electrolyser costs so hydrogen and oxygen can now be conveniently sourced from water

* New Safeflame ® burner designs produce a new flame with no lightback, less intense, controllable and safer.

* So, for the first time unique benefits of hydrogen and oxygen can now be used safely from a convenient source of supply.

* Flame brazing is used in ALL industries including Automotive, Aerospace, HVACR and Heat pumps and many more sectors.

* Manual and automated methods

* HVACR and heat pumps is a huge global industry.

* Dominant “ Joining process ” is FLAME BRAZING

* Manually flame brazing holding a gas/oxygen hand torch

Types of Electrolysis

Range of Commercially available electrolysers

Safeflame uses PEM cell:

* Separate gases have two separate outlet connections for Hydrogen and Oxygen.

* Acidic (PEM) with no KOH but uses built-in catalyst

Others use HHO Cell:

• HHO mixed gas has one outlet connection.

• Hydrogen and oxygen gas immediately mix together

• Alkaline type with KOH (electrolyte)

Pre-Mixed & Post-Mixed

Pre-Mixed: An “ unpiloted ” single-orifice Gas-Oxygen Burner nozzle. HHO machines use this kind of pre-mixed burner nozzle.

Post-Mixed Multi-orifices Burner Nozzle , our Hydrogen Brazing Machine use this kind of post-mixed burner nozzle. Dominant “ Joining process ” is FLAME BRAZING

Range of Burners and Torches

Single and Double Safeflame Torches

Various sizes of Safeflame burner nozzles are available.

Size range – The higher the number the smaller the port size.

Burners and torches can be designed according to customers ’ requirements.

Health and Safety

* The system eliminates the usage of Compressed gas cylinders and reduces the possibility of gas cylinder explosion.

* The Hydrogen flame is environmentally friendly. The combustion of Hydrogen and Oxygen produces water vapor and does not produces CO2 emissions, resulting in a better working

environment for the brazing operators.

• The gas pressure inside the Electrolyser is very low (< 0.5 bar) which is below any safety

regulation for high pressure vessels .

• No hydrogen and oxygen gases storage ; machine produces the hydrogen and oxygen

gases on demand.

• Brazing does not require the operator to wear any special glasses.

• The fumes are reduced by about 60-70%

Quality.

T he flame is neutral and concentrated; heat is therefore localised and

does not spread, eliminating the risk to overheat the brazing piece and nearby

assembly components. Such a flame drastically reduces the oxidation inside the

brazed pipes. For the refrigeration/air-conditioning industry with less oxidation

inside the copper tubing will result in extended life-time of the compressor.

• Thanks to the neutral flame and high temperature the brazing alloy penetrates deeper into the joint producing stronger connections.

• The Hydrogen and Oxygen gases from the electroly s er are mixed automatically at the tip of the torch thus eliminating the human intervention, the flame ’ s quality is always consistent therefore quality of brazing improves .

|

Model |

SF2000 |

SF4000 |

SF6000 |

SF8000 |

SF1000 |

SF12000 |

|

Flow Rate ( Litres ) |

2 |

4 |

6 |

8 |

10 |

12 |

|

H2 Output( LPM ) |

2 |

4 |

6 |

8 |

10 |

12 |

|

O2 Output( LPM ) |

1 |

2 |

3 |

4 |

5 |

6 |

|

Power Supply(AC) |

220/110V 50/60Hz |

220/110V 50/60Hz |

220/110V 50/60Hz |

220/110V

|

220/110V

|

220/110V

|

|

Max Power Consumption (W) |

700 |

1300 |

1800 |

2300 |

2800 |

3300 |

|

Water Tank Capacity (L) |

8 |

8 |

8 |

8 |

20 |

20 |

|

Water Consumption (ML/HR) |

120 |

240 |

360 |

480 |

600 |

720 |

|

Dimensions(CM) (H*W*D) |

57*39*55 |

57*39*55 |

57*39*55 |

57*39*55 |

70*50*78 |

70*50*78 |

|

Weight (KG) |

35 |

38 |

40 |

42 |

90 |

100 |