- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mosun

-

Voltage:

-

220-240V SINGLE PHASE

-

Dimension(L*W*H):

-

3680*980*1250MM

-

Weight:

-

1200 kg

-

Warranty:

-

1 Year

-

Marketing Type:

-

HOT PRODUCT

-

Model:

-

MS-A4055

-

MAX SHEET SIZE (BEFORE PROCESSING) (W*L):

-

400*550MM

-

MIN SHEET SIZE (BEFORE PROCESSING) (W*L):

-

240*280MM

-

DIE CUTTING MATERIAL THICKNESS:

-

0.13-0.5MM

-

CREASING MATERIAL THICKNESS:

-

0.4MM

-

MAX FINAL PRODUCT SIZE:

-

376*530MM

-

MIN FINAL PRODUCT SIZE:

-

50*80MM

-

FEEDER STACK HEIGHT:

-

500MM

-

MOULD THICKNESS:

-

0.8MM

-

MOULD SIZE:

-

160*100MM-400*560MM

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

6000 CYCLES PER HOUR

-

Max. workable width:

-

550mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mosun

-

Voltage:

-

220-240V SINGLE PHASE

-

Dimension(L*W*H):

-

3680*980*1250MM

-

Weight:

-

1200 kg

-

Warranty:

-

1 Year

-

Marketing Type:

-

HOT PRODUCT

-

Model:

-

MS-A4055

-

MAX SHEET SIZE (BEFORE PROCESSING) (W*L):

-

400*550MM

-

MIN SHEET SIZE (BEFORE PROCESSING) (W*L):

-

240*280MM

-

DIE CUTTING MATERIAL THICKNESS:

-

0.13-0.5MM

-

CREASING MATERIAL THICKNESS:

-

0.4MM

-

MAX FINAL PRODUCT SIZE:

-

376*530MM

-

MIN FINAL PRODUCT SIZE:

-

50*80MM

-

FEEDER STACK HEIGHT:

-

500MM

-

MOULD THICKNESS:

-

0.8MM

-

MOULD SIZE:

-

160*100MM-400*560MM

Product Appearance

Product Description

USAGE&SPECIFICATION

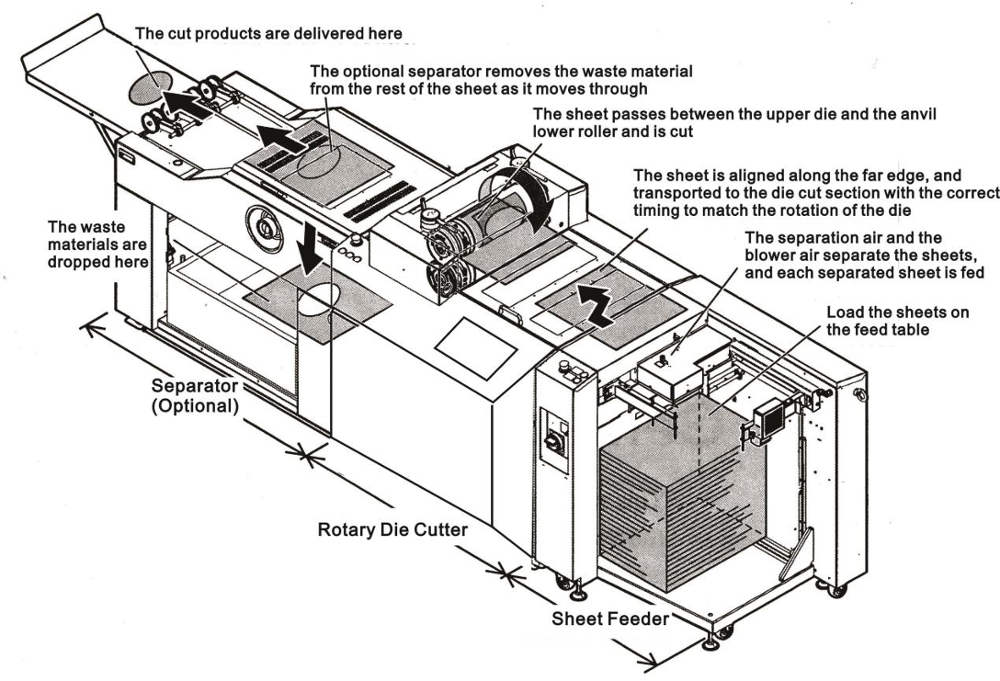

Roller Die Cutting machine is to cut the paper with the mould. It can be applied to normal paper, coated paper and cardboard, (the following paper cannot be processed: composite paper (covered with polypropylene) or plastic film). Speed can reach 6000 cycles per hour. It can remove the waste automatically, easy to operate and save time with the efficient work.

|

|

MODEL

|

MS-A4055

|

MS-A4874

|

MS-A5575

|

|||

|

SHEET SIZE (BEFORE PROCESSING) (W×L)

|

MAX SIZE

|

400*550MM

|

480*740MM

|

550*750MM

|

|||

|

|

MIN SIZE

|

240*280MM

|

240*280MM

|

240*280MM

|

|||

|

MATERIAL

THICKNESS

|

DIE CUTTING

|

0.13-0.5MM

|

0.2-0.5MM

|

0.15 MM–0.5MM

|

|||

|

|

CREASING (MAX)

|

0.4MM

|

0.4MM

|

0.4MM

|

|||

|

FINAL PRODUCT SIZE WITH SEPARATOR

FINAL PRODUCT:W×L |

MAX SIZE

|

376*530MM

|

456*720MM

|

526*730MM

|

|||

|

|

MIN SIZE

|

50*80MM

|

50*80MM

|

50*80MM

|

|||

|

MOULD SIZE

|

MAX SIZE

|

400*560MM

|

480*750MM

|

550*760MM

|

|||

|

|

MIN SIZE

|

160*100MM

|

160*110MM

|

160*100MM

|

|||

|

MOULD THICKNESS

|

MOULD THICKNESS

|

0.8MM

|

1MM

|

1MM

|

|||

|

MIN DISCHARGE WIDTH

|

MIN DISCHARGE WIDTH

|

5MM

|

6MM

|

5MM

|

|||

|

X/Y DIRECTION DIE CUTTING ACCURACY

|

|

±0.1MM

|

±0.1MM

|

±0.1MM

|

|||

|

FEEDER STACK HEIGHT

|

|

500MM

|

500MM

|

500MM

|

|||

|

MAX PRODUCTION SPEED (CYCLES PER HOUR)

|

|

6000

|

6000

|

6000

|

|||

|

VOLTAGE

|

|

SINGLE PHASE 200~240V,50/60HZ

|

|

|

|||

|

MAIN MOTOR POWER

|

|

2.5KW

|

4.5KW

|

8.2KW

|

|||

|

WEIGHT(NET WEIGHT)

|

|

1100KG

|

2440KG

|

2580KG

|

|||

|

MACHINE SIZE(L*W*H)

|

|

3680*980*1250

|

4690*1310*1620

|

5660*1450*1620

|

|||

Details Images

Feed Section

Vacuum belt feeding enables superior feeding with easy setup and operation. An ultrasonic sensor is used for double feed detection on a wide range of substrates.

Transport Section

Sheets are registered by vacuum belt and position is firmly secured with gripper rollers for high quality finish. Servo motor driven gripper rollers ensure the die cut position without effecting processing speed.

Die Cutting Section

Rigid magnetic upper roller and solid lower anvil roller ensure high quality die cutting. Uniquely designed die cutting section enables easy and quick die setting. Both 0.6mm and 0.8mm/0.0236’’ and 0.0315’’ thickness of flexible die plates can be used.

Separator Section

The separator removes the waste from the finished product and delivers it to the waste bin. Air cylinder driven separator pins and sir jets can be used depending on size of the waste.

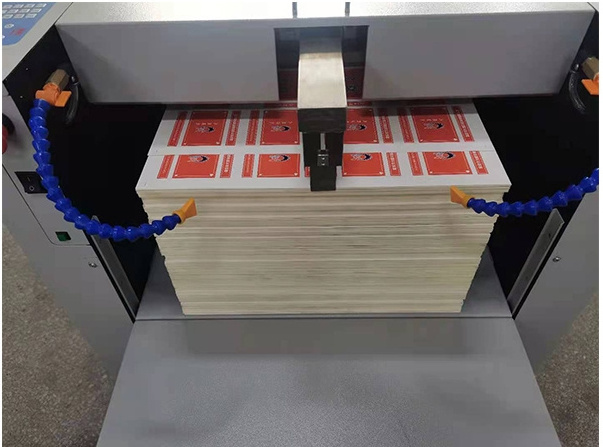

Samples

Ralated Products

CLICK HERE FOR MORE

Certifications

Packing & Delivery

Customers Visit and Feedback

Hot Searches