- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2320*1300*1100mm

-

Weight:

-

500 KG

-

Heating type:

-

Electric

-

Coating method:

-

Roll coating

-

Coating width:

-

0-320mm

-

Coating thickness:

-

5-10um

-

Work speed:

-

15m/min

-

Inner hole diameter of film roll:

-

3 core

-

Coating material:

-

PET.CPP.CPE.nylon.Foil.paper

-

Application1:

-

inject printing

-

After Warranty Service:

-

Online support

-

Marketing Type:

-

New Product 2020

Quick Details

-

Core Components:

-

other

-

Voltage:

-

220V 50/60Hz

-

Place of Origin:

-

Anhui, China

-

Dimension(L*W*H):

-

2320*1300*1100mm

-

Weight:

-

500 KG

-

Heating type:

-

Electric

-

Coating method:

-

Roll coating

-

Coating width:

-

0-320mm

-

Coating thickness:

-

5-10um

-

Work speed:

-

15m/min

-

Inner hole diameter of film roll:

-

3 core

-

Coating material:

-

PET.CPP.CPE.nylon.Foil.paper

-

Application1:

-

inject printing

-

After Warranty Service:

-

Online support

-

Marketing Type:

-

New Product 2020

Product Description

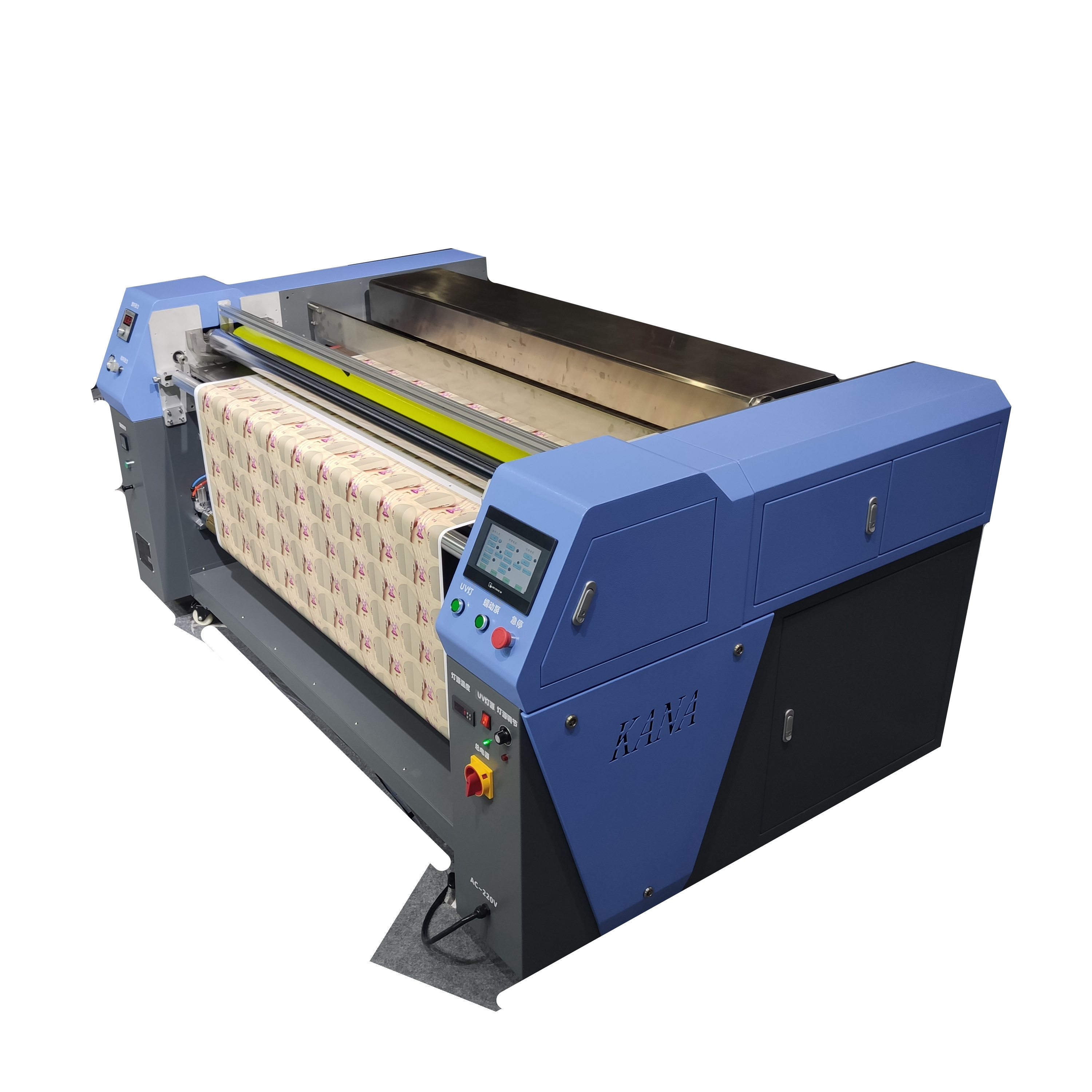

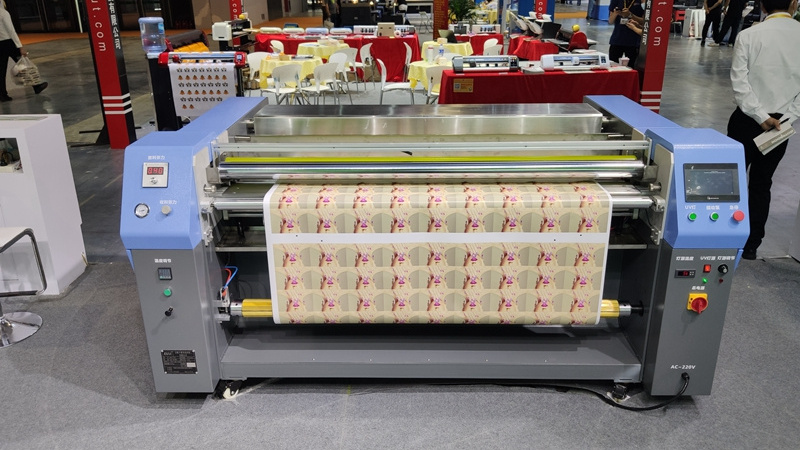

What is KANA liquid coating technology?

Kana liquid coating cured by Kana LED UV instant curing coating machine forms a glossy or matte protective film on the surface of soft roll inkjet printing product.

Kana coating is high temperature and low temperature resistant (-20℃ to 68 ℃), anti-yellowing, anti-fracture, scratch-resistant, friction-resistant, environmental friendly, pollution free, safe and energy saving(5kw), low cost as only 0.4$/m².

Under real outdoor test, Kana coating can enduring at least 2 years of sun burning, UV light, water pouring.

Product Paramenters

|

Machine Name

|

LED UV instant curing liquid coating machine

|

|

Control System

|

PLC with Touch Screen. Automatic Running

|

|

Model Number

|

KANA-1700

|

|

Working Width

|

1650mm custom length is ok

|

|

Power

|

5kw

|

|

Voltage

|

220V 50/60Hz

|

|

Speed

|

1-12m/min

|

|

Coating Thickness

|

5~10um

|

|

Working Thickness

|

≤5mm

|

|

Curing System

|

LED - UV

|

|

LED Life Expectancy

|

15000 hours

|

|

Coating Type

|

SC-6748 glossy coating / SC-6738 matte coating

|

|

Varnish Component

|

99% solid content and 1% solvents.

|

|

Glossy Varnish

|

SC-6748 80-85 ° Glossiness (60° vanceometer)

|

|

Matte Varnish

|

SC-6738 20 ° Glossiness (60° vanceometer)

|

|

Storage

|

1 year. (25℃ at room temperature, keep away from light)

|

|

Package

|

5kg in PVC Sealed Bottle

|

|

Hardness

|

≥2H (pencil hardness)

|

|

Consumption

|

6-8g/㎡ Max 600 square meter / 5 kg

|

|

Drying speed

|

40-80Ft/Min/80W/Cm/Lamp

|

|

Viscosity

|

coating with 4 jar in 22 second/25℃

|

Our Advantages

Kana liquid coating film VS PVC cold laminating film

Due to the limits of the cold laminating film, micro-bubbles (marked in red) are prone to appear on the surface of the product, and the surface of the liquid coating is flat without defects.

Subjective visual comparison leads to two conclusions:

1.PVC laminating film application will darken printing colors due to lower transmittance.

2.KANA UV curable coating has better color consistency due to the higher transmittance.

untreated sample VS Kana liquid coating sample

E2000=2.9

untreated sample VS PVC cold lamination film sample

E2000=3.4

Comprehensive dE (color difference) value comparison leads to a conclusion:

Kana liquid coating has a lower color difference range. Cold laminating film affected by the light transmittance reduces the brightness of the sample. Kana liquid coating does less change of light and shade, and also has better chromaticity enhancement.

|

Comparison

|

PVC laminating film(×)

|

KANA UV coating(√)

|

|

Cost

|

Due to the different sizes of the material, cold laminated film requires a larger inventory

, and the scrap rate is close to 15% |

Coating on substrates of various formats only needs 6 to 10 grams per square meter, which can reduce waste to 2%

|

|

Application

|

Poor ductility, inconvenient to use on bus car trailer van sticker

|

Good ductility and easy to use on bus car trailer van sticker

|

|

Quality

|

Prone to shrinkage, breakage, separation and wrinkles

|

No break, no yellowing, scratch resistance,

(Aging test report, scratch test in video) |

|

Transmittance

|

Low transmittance will darken printing color

|

It has high light transmittance and good color consistency. The surface brightness of the coating can reach 90°

|

|

Environmental friendly

|

white pollution, air

pollution,water and soil pollution. it takes 30 years to decompose. |

The coating and the substrate are better combined, and there is no volatile organic compounds.

|

|

Human hazards

|

Above 65℃, the laminated PVC film will produce harmful substances and gases such as lead, tin, and chlorine.

|

No harm to human body(Heavy metal and halogen test report)

|

|

Smell

|

Heavy odor: the odor is difficult to dissipate in a confined space.

|

Only a little smell of epoxy resin. 1% solvents solves the problem of volatility and irritation.

|

Certifications

YOU CAN DOWNLOAD OUR TEST REPORT BY BELOW LINK

https://drive.google.com/drive/folders/1RxkAYGQeX6t-OkrCDNMiC2ykQulrE2U5?usp=sharing

|

A

|

KANA coating performance test report (British SGS company)

|

|

1

|

Aging test report (coating has no quality change during 500 hours of water spraying and UV light cycle)

|

|

2

|

High temperature resistance test report (coating has no quality change under 68℃ within 48 hours)

|

|

3

|

Low temperature resistance test report (coating has no quality change under -20℃ within 48 hours)

|

|

B

|

KANA coating environmental protection test report (China National Coating Quality Supervision and Inspection Center, British SGS company)

|

|

1

|

Heavy metal and halogen test report provided by SGS

Test method: burn in a high-pressure oxygen bomb tank, the absorption of combustion products is analyzed by ion chromatography, and no volatile toxic gas will be generated

|

|

2

|

SGS inspection report provided by SGS

Test method: SVHC 211 high concern substance screening, SVHC test result ≤0.1% (W/W), pass the test standard

|

|

3

|

Volatile Organic Compound (VOC) Test Report

(By China National Coatings Quality Supervision and Inspection Center)

Test method: test condition (105±2)℃/h/about 1g, the test result is 246g/L |

Hot Searches