- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.5Mpa (25mm thickness)

-

Density (kg/m³ ):

-

128

-

Length:

-

7200/3600mm(7320/3660mm)

-

Working Temperature:

-

1100℃

-

Fiber Diameter:

-

3-5μm

-

Shrinkage (1800 ℉, 3h):

-

-3%

-

Thermal Conductivity:

-

0.06-0.12

-

Model Number:

-

LYTX-1260T

-

Brand Name:

-

LUYANGWOOL

-

Place of Origin:

-

Shandong, China

-

Description:

-

LUYANGWOOL STD/HP/HA/HZ BLANKET

-

Classification Temperature (℃ ):

-

1260/1260/1350/1430

-

Al2O3:

-

≥43/44/52/35

-

SiO2:

-

≥54/55/47/49

-

ZrO2:

-

-/-/-/≥15

-

Shot Content (%):

-

≤15/15/15/12

-

Density (kg/m3):

-

64/96/128

-

Feature 1:

-

Excellent thermal shock resistance

-

Feature 2:

-

Excellent thermal stability

-

Feature 3:

-

High tensile strength

Quick Details

-

Thickness:

-

6mm-50mm

-

Width:

-

100mm-1220mm

-

Chemical Composition:

-

Al2O3+SIO2≥99%

-

Ultimate Strength (≥ MPa):

-

0.5Mpa (25mm thickness)

-

Density (kg/m³ ):

-

128

-

Length:

-

7200/3600mm(7320/3660mm)

-

Working Temperature:

-

1100℃

-

Fiber Diameter:

-

3-5μm

-

Shrinkage (1800 ℉, 3h):

-

-3%

-

Thermal Conductivity:

-

0.06-0.12

-

Model Number:

-

LYTX-1260T

-

Brand Name:

-

LUYANGWOOL

-

Place of Origin:

-

Shandong, China

-

Description:

-

LUYANGWOOL STD/HP/HA/HZ BLANKET

-

Classification Temperature (℃ ):

-

1260/1260/1350/1430

-

Al2O3:

-

≥43/44/52/35

-

SiO2:

-

≥54/55/47/49

-

ZrO2:

-

-/-/-/≥15

-

Shot Content (%):

-

≤15/15/15/12

-

Density (kg/m3):

-

64/96/128

-

Feature 1:

-

Excellent thermal shock resistance

-

Feature 2:

-

Excellent thermal stability

-

Feature 3:

-

High tensile strength

Product Description

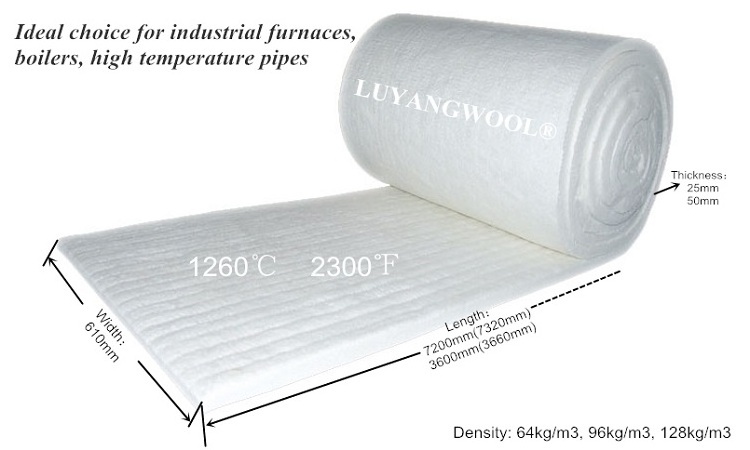

LUYANGWOOL® CERAMIC FIBER BLANKET / RCF Blanket

Luyangwool® ceramic fiber blanket is high strength, needled insulating blanket that is made from Luyangwool® ceramic fiber bulk.The combination of long spun fibers and needling operation produce tough, resilient and strong blankets, which resist tearing both before and after heating.

Luyangwool® ceramic fiber blanket is completely inorganic and available in a variety of temperature grades, densities, and sizes. Luyangwool® ceramic fiber blanket can be folded, compressed and encapsulated to produce module.

Luyangwool® ceramic fiber blanket is completely inorganic and available in a variety of temperature grades, densities, and sizes. Luyangwool® ceramic fiber blanket can be folded, compressed and encapsulated to produce module.

Features

* Excellent thermal shock resistance * Excellent heat insulation

*Excellent thermal stability * Excellent Shock and chemical attack resistant

* High tensile strength * Excellent chemical stability

* Low thermal conductivity * Low heat storage

* Excellent thermal insulation,fireproof and sound absorption

* Excellent thermal shock resistance * Excellent heat insulation

*Excellent thermal stability * Excellent Shock and chemical attack resistant

* High tensile strength * Excellent chemical stability

* Low thermal conductivity * Low heat storage

* Excellent thermal insulation,fireproof and sound absorption

|

Product name

|

LUYANGWOOL® ceramic fiber blanket

|

|

Classification

t

emperature

|

1260℃

(2300℉)

|

|

Density

|

64kg/m3, 96kg/m3, 128kg/m3

|

|

Size

|

15000*610/1220*10mm

14400/14640*610/1220*12.5mm 7200/7320*610/1220*20mm 7200/7320*610/1220*25mm 5000*610/1220*30mm 4500*640/1220*25mm

3600/3660*610/1220*50mm

Blanket size can be customized.

|

|

Package

|

1.Plastic coated woven bag

2.inner plastic bag, outside carton box

3.inner plastic bag, outside carton box, then packed on pallets

|

|

Payment

|

T/T,L/C,D/A,D/P,Western Union,MoneyGram

30% deposits, 70% balance before delivery

Payment method can be negotiated. |

|

MOQ

|

1 roll

|

|

Sample

|

We supply small samples for free !

|

Typical Parameters

|

Description

|

LUYANGWOOL®

STD BLANKET |

|

|

LUYANGWOOL®

HP BLANKET |

|

LUYANGWOOL®

HA BLANKET |

|

LUYANGWOOL®

HZ BLANKET |

|

|||||||||

|

Classification Temperature (℃ )

|

1260

|

|

|

1260

|

|

1350

|

|

1430

|

|

|||||||||

|

Chemical Composition (%)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Al2O3

|

≥43

|

|

|

≥44

|

|

≥52

|

|

≥35

|

|

|||||||||

|

SiO2

|

≥54

|

|

|

≥55

|

|

≥47

|

|

≥49

|

|

|||||||||

|

ZrO2

|

-

|

|

|

-

|

|

-

|

|

≥15

|

|

|||||||||

|

Color

|

White

|

|

|

White

|

|

White

|

|

White

|

|

|||||||||

|

Shot Content (%)

|

≤15

|

|

|

≤15

|

|

≤15

|

|

≤12

|

|

|||||||||

|

Density (kg/m³)

|

64

|

96

|

128

|

96

|

128

|

96

|

128

|

96

|

128

|

|||||||||

|

Tensile Strength (kPa)

|

30

|

50

|

70

|

50

|

70

|

50

|

70

|

50

|

70

|

|||||||||

|

Permanent Linear Shrinkage (%)

|

1000℃ x 24h ≤2.5

|

|

|

1100℃ x 24h ≤2.5

|

|

1200℃ x 24h ≤3.0

|

|

1350℃ x 24h ≤3.0

|

|

|||||||||

|

Thermal Conductivity (W/m·K)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

200℃

|

0.07

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

|||||||||

|

400℃

|

0.12

|

0.11

|

0.10

|

0.11

|

0.10

|

0.11

|

0.10

|

0.11

|

0.10

|

|||||||||

|

600℃

|

0.20

|

0.19

|

0.18

|

0.19

|

0.17

|

0.18

|

0.16

|

0.16

|

0.15

|

|||||||||

|

800℃

|

0.30

|

0.23

|

0.20

|

0.23

|

0.20

|

0.22

|

0.20

|

0.21

|

0.19

|

|||||||||

|

1000℃

|

0.40

|

0.32

|

0.27

|

0.31

|

0.26

|

0.30

|

0.26

|

0.30

|

0.26

|

|||||||||

Application

Applications

1.Ceramic industry:

Kiln car insulation and seals,

Continuous and batch kilns

Continuous and batch kilns

2.Steel industry:

Heat treating and annealing furnaces,

Furnace door linings and seals,

Soaking pit covers and seals,

Furnace hot face repairs,

Reheating furnace and ladle covers

3.Refining and petrochemical industry:

Reformer and pyrolysis lining,

Tube seals,gaskets and expansion joints,

High temperature pipe,duct and turbine insulation

Crude oil heater linings

Other typical application:

* Industry furnace wall lining

*

Back lining material

*

Fire prevention

*

High-temperature tube heat insulation material

*

Module/folding block processing material

*

Filling and sealing material in high temperature environment.

* Sound-absorbing or high temperature filtration materials.

* Sound-absorbing or high temperature filtration materials.

Production Line

Packing & Delivery

Shipping

1. FEDEX/DHL/UPS/TNT/EMS or shipped by Alibaba parcel for samples.

2. By Sea for batch goods.

3. Customers specify freight forwarders or negotiate shipping methods!

4. Delivery Time: 3-15 days for common shape samples, 7-45 days for batch goods.

1. FEDEX/DHL/UPS/TNT/EMS or shipped by Alibaba parcel for samples.

2. By Sea for batch goods.

3. Customers specify freight forwarders or negotiate shipping methods!

4. Delivery Time: 3-15 days for common shape samples, 7-45 days for batch goods.

Hot Searches