- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Aluminum Alloy

-

Process:

-

Precision Die Casting

-

Surface treatment:

-

Sand Blasting

-

Standard:

-

GB ASTM AISI DIN BS

-

Service:

-

OEM ODM Customised

-

Application:

-

Auto Parts

-

Hardness:

-

≥HB60

-

Tensile Strength:

-

≥220MPa

-

Designs:

-

As per the customer's drawings

-

OEM:

-

Yes

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

R&H

-

Model Number:

-

Aluminum Die Casting Parts

-

Material:

-

Aluminum Alloy

-

Process:

-

Precision Die Casting

-

Surface treatment:

-

Sand Blasting

-

Standard:

-

GB ASTM AISI DIN BS

-

Service:

-

OEM ODM Customised

-

Application:

-

Auto Parts

-

Hardness:

-

≥HB60

-

Tensile Strength:

-

≥220MPa

-

Designs:

-

As per the customer's drawings

-

OEM:

-

Yes

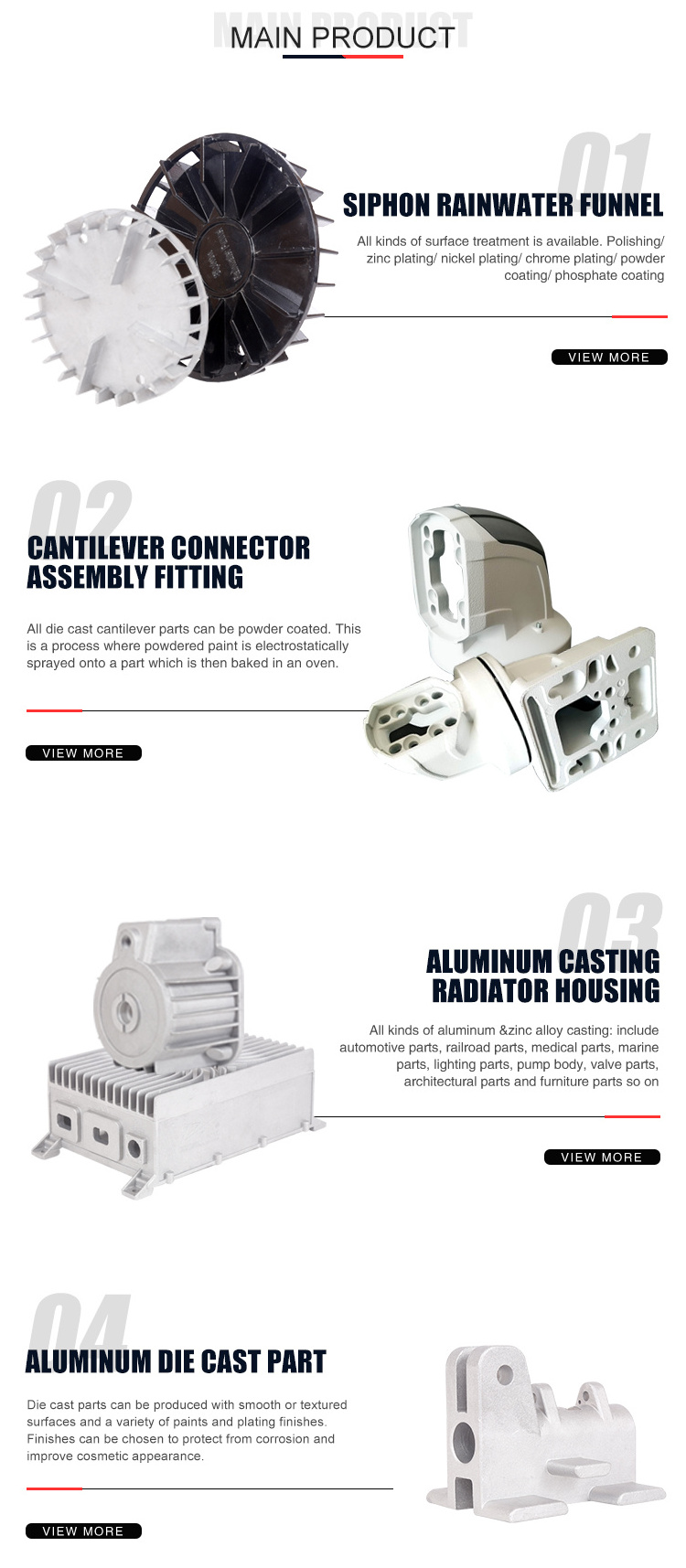

Hign Precision Gravity Die Casting Good Surface Die Casting Product Zinc Die Casting

Hign Precision Gravity Die Casting Good Surface Die Casting Product Zinc Die Casting

| Material | aluminum alloy A380,A360.ADC12,Zinc alloy 3#zinc,5#zinc and 7#zinc,etc |

| Designs |

1.As per the customer’s drawings 2.As per the customer’s sample |

|

Surface

treatment |

1.As-Cast

coated to achieve corrosion resistance. Cast parts are typically broken away from the casting sprue, leaving rough marks at the gate locations. Most castings will also have visible marks

left by the ejector pins.

Surface finish for as-cast zinc alloys is commonly 16-64 microinch Ra.

|

|

2.Anodizing (Type II Or Type III)Aluminum is typically anodized. Type II anodizing creates a corrosion-resistant oxide finish. Parts can be anodized in different colors—clear, black, red and gold are most common. Type III is a thicker finish and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. Anodized coatings are not electrically conductive. |

|

|

3.Powder Coating

where powdered paint is electrostatically sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion resistant layer that is more durable than standard wet painting methods. A wide variety of colors are available to create the desired aesthetic. |

|

|

4.Plating

nickel, nickel, brass, tin, chrome, chromate, Teflon, silver and gold. |

|

|

5.Chemical Film

and magnesium from corrosion and improve the adhesion of paints and primers. Chemical film conversion coatings are electrically conductive. |

|

| Software | Pro/E, Auto CAD, CAXA UG, CAD/CAM/CAE |

| Service | OEM service available |

| Products |

All kinds of aluminum &zinc alloy casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

| 2.Third Party inspection available upon requirement | |

| Packing | Pearl cotton bag inner and plastic pallet and export carton |

| Payment | T/T,L/C |