- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2500

-

Name:

-

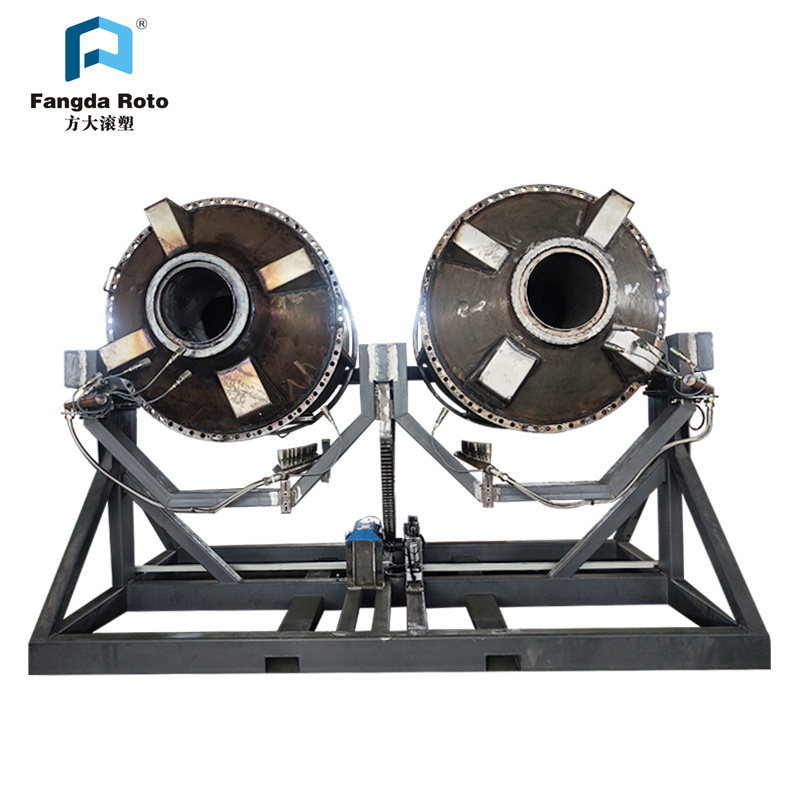

Rotational Molding Machine

-

Product Type:

-

Vertical Tanks Making Machine

-

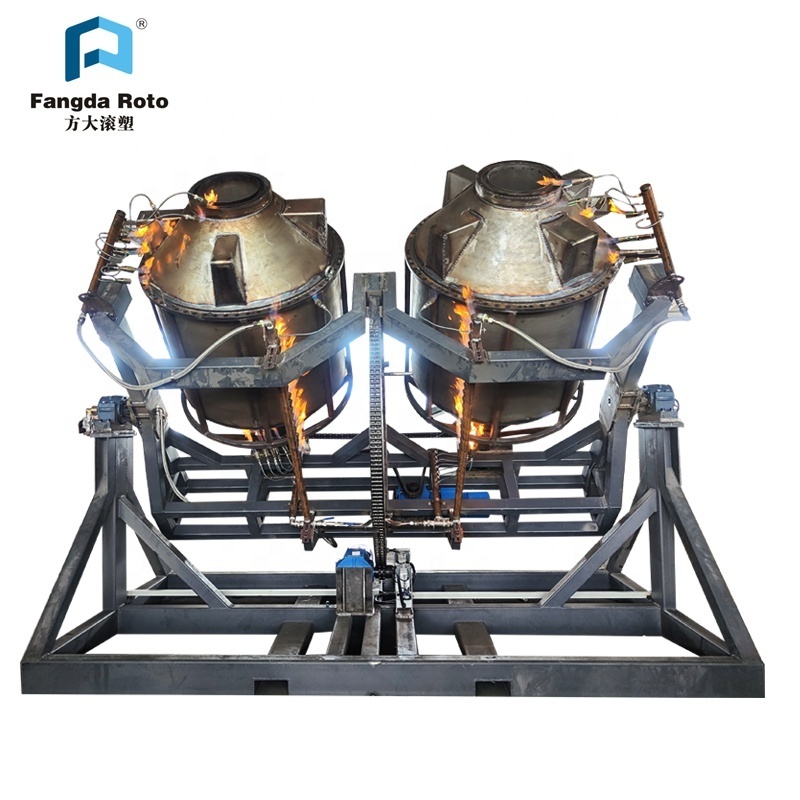

Heating Type:

-

Open Flame

-

Work type:

-

Open Flame Swing

-

Production Efficiency:

-

It can make two tanks about per 45 minutes

-

Fuel:

-

LPG or Natural Gas

-

Tank Material:

-

polyethylene

-

Certification:

-

CE

-

Surface Coating:

-

Antitrust Paint

-

Machine Material:

-

Steel Plate

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fangda Roto

-

Voltage:

-

customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2500

-

Name:

-

Rotational Molding Machine

-

Product Type:

-

Vertical Tanks Making Machine

-

Heating Type:

-

Open Flame

-

Work type:

-

Open Flame Swing

-

Production Efficiency:

-

It can make two tanks about per 45 minutes

-

Fuel:

-

LPG or Natural Gas

-

Tank Material:

-

polyethylene

-

Certification:

-

CE

-

Surface Coating:

-

Antitrust Paint

-

Machine Material:

-

Steel Plate

Product Description

Fangda Roto's open flame rock and roll machine is the simplest type of rotomolding machine,take up very little floor space compared to other machines,and i

t is suitable for the production of vertical water tanks.

This machine has been exported to Mexico, Peru, Yemen, Bolivia and so on.

■ Application:suitable for production of vertical water tanks.

■ Heat Source:natural gas,liquefied gas.

■ Heating method: open flame

■ Fully automatic PLC control system,high production efficiency.

■ PLC programming, it can produce 3 layer tank.

■ Application:suitable for production of vertical water tanks.

■ Heat Source:natural gas,liquefied gas.

■ Heating method: open flame

■ Fully automatic PLC control system,high production efficiency.

■ PLC programming, it can produce 3 layer tank.

|

Specification of the Rock and Roll Rotomolding Machine

|

|

|

|

|

||||

|

Product Name

|

|

Open Flame Rock and Roll Rotomolding Machine

|

|

|

||||

|

Machine Material

|

|

Steel Plate

|

|

|

||||

|

Surface Coating

|

|

Antitrust Paint

|

|

|

||||

|

Heating Source

|

|

LPG,Natural Gas

|

|

|

||||

|

Gas Switch

|

|

Schneider

|

|

|

||||

|

Touch Screen

|

|

Siemens

|

|

|

||||

|

Frequency Changer

|

|

Siemens

|

|

|

||||

|

This machine is a customized product,for more details,please contect us.

|

|

|

|

|

||||

Product Advantages

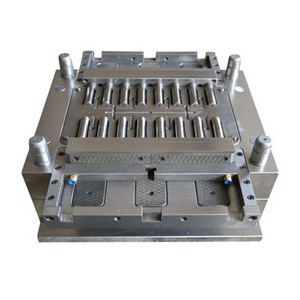

1. Low cost rotational molding: the same size specifications of the product, the cost of rotational molding mold is about blow molding, injection mold costs 1/3 to 1/4;

2. Edge strength of rotomoulded products is good, rotational molding can realize the thickness of the edge of the product

more than 5 mm, and completely solve the problem that the edge of the hollow product is thin;

3. Rotational molding can place a variety of accessories;

4. The shape of rotomolding products can be very complicated, and the thickness of more than 5 mm;

5. Rotational molding can produce fully enclosed products;

6. Rotational molding products can be filled foam material, to achieve insulation;

7. No need to adjust the mold, rotational molding wall thickness can be freely adjusted(2mm above);

8. The product hollow seamless, but you can adjust the wall thickness, so that products with high strength;

9. Can provide a variety of surface pattern processing, production of various color products, anti-UV anti-aging treatment.

Main Products

packing & Shipping

Hot Searches