- Product Details

- {{item.text}}

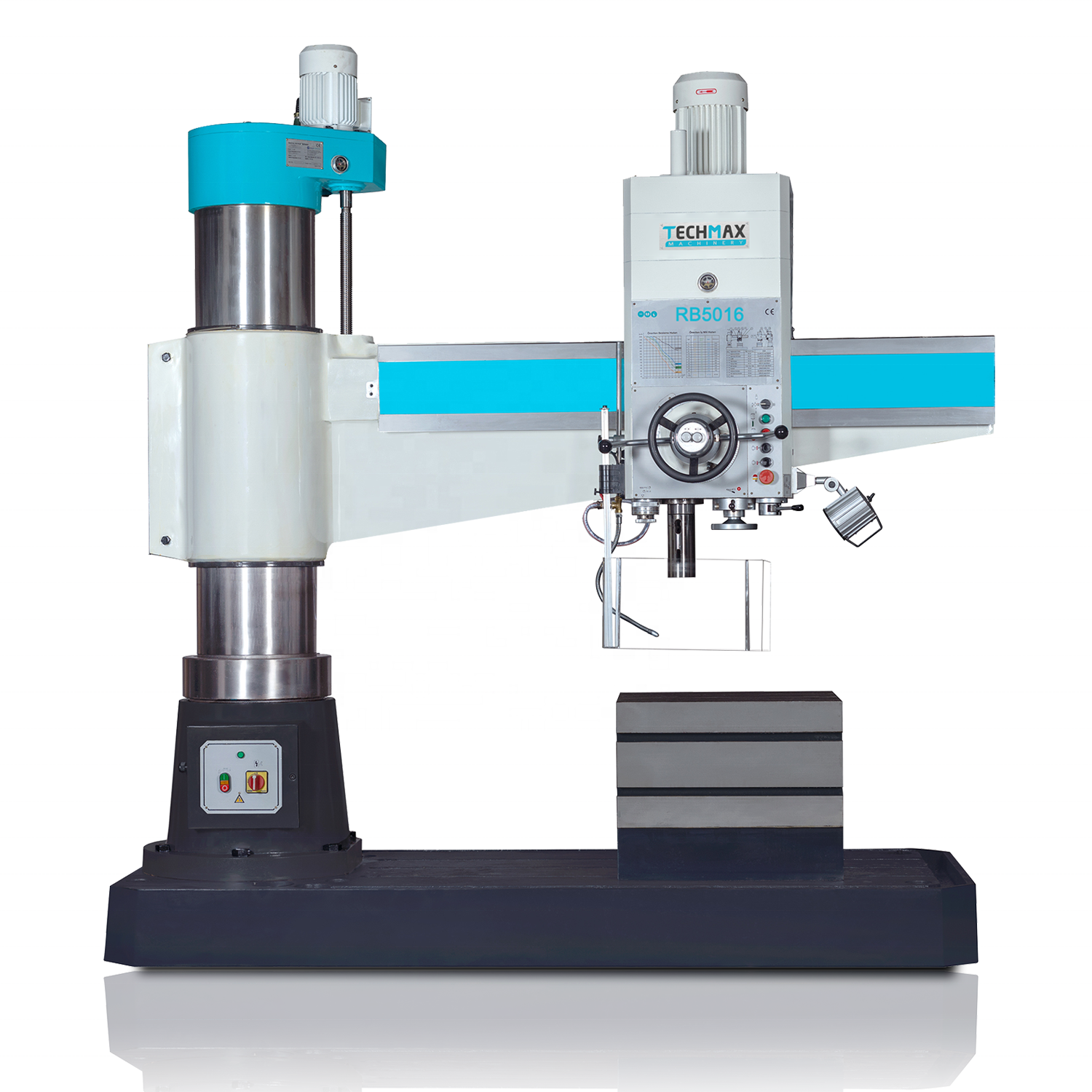

Quick Details

-

Drilling Speed:

-

25-2000

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Techmax

-

Model Number:

-

RB 5016

-

Voltage:

-

As per the client's request

-

Dimension(L*W*H):

-

2500x1060x2650mm

-

Power (kW):

-

4

-

Weight (KG):

-

3650 KG

-

Max. drilling capacity:

-

50mm

-

Distance from spindle axis to column:

-

350-1600mm

-

Distance from spindle nose to base:

-

320-1220mm

-

Diameter of column:

-

350mm

-

Spindle taper:

-

MT5

-

Spindle travel:

-

315mm

-

Spindle speed range:

-

25-2000rpm

-

Spindle speed step:

-

16

-

Spindle feed speed:

-

0.04-3.2mm/r

-

Main motor power:

-

4kw

Quick Details

-

type:

-

Radial Drilling Machine

-

Max. Drilling Dia. (mm):

-

50

-

Range of Spindle Speed(r.p.m):

-

25 - 2000 r.p.m

-

Drilling Speed:

-

25-2000

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Techmax

-

Model Number:

-

RB 5016

-

Voltage:

-

As per the client's request

-

Dimension(L*W*H):

-

2500x1060x2650mm

-

Power (kW):

-

4

-

Weight (KG):

-

3650 KG

-

Max. drilling capacity:

-

50mm

-

Distance from spindle axis to column:

-

350-1600mm

-

Distance from spindle nose to base:

-

320-1220mm

-

Diameter of column:

-

350mm

-

Spindle taper:

-

MT5

-

Spindle travel:

-

315mm

-

Spindle speed range:

-

25-2000rpm

-

Spindle speed step:

-

16

-

Spindle feed speed:

-

0.04-3.2mm/r

-

Main motor power:

-

4kw

❶

With wide range of speed and feed, with manual, power and fine feeds. The feed of machines are very easily engaged and disengaged at any time.

❷

With safe and reliable feed safety machine, all parts easy operation and change.

❸

All controls centralized on the headstock easy operation and change. Clamping for all assemblies and speed change of spindle achieved by hydraulic, sensitive and reliable.

❹ Main parts are made by machine center which import form KIA with high precision and efficiency, ensuring reliability and high quality

❹ Main parts are made by machine center which import form KIA with high precision and efficiency, ensuring reliability and high quality

❺

Integrating technology for casting parts is excellent, adopting casting equipment, ensuring high quality of material for basic parts.

❻

Spindle parts are made by special high quality steel heat treatment to be made by first class equipments, ensuring high strength and durability.

❼ Main gears are machined by gear grinding, the machine ensuring high precision and low noise.

❼ Main gears are machined by gear grinding, the machine ensuring high precision and low noise.

❽

Importable electrical components with CE, CSA, UL standard.

|

SPECIFICATION

|

RB 5016

|

RB 5020

|

|

Max. drilling capacity

|

50 mm

|

50 mm

|

|

Distance from spindle axis to column

|

350-1600 mm

|

350-2000 mm

|

|

Distance from spindle nose to base

|

320-1220 mm

|

320-1220 mm

|

|

Diameter of column

|

350 mm

|

350 mm

|

|

Spindle taper

|

MT5

|

MT5

|

|

Spindle travel

|

315 mm

|

315 mm

|

|

Spindle speed range

|

25-2000 rpm

|

25-2000 rpm

|

|

Spindle speed step

|

16 steps

|

16 steps

|

|

Spindle feed speed

|

0.04-3.2mm/r

|

0.04-3.2 mm/r

|

|

Spindle feed speed step

|

16 steps

|

16 steps

|

|

Rotary angle of rocker in horizontal plane

|

360 °

|

360 °

|

|

Table size

|

630x500x500 mm

|

630x500x500 mm

|

|

Base-table size

|

2400x1000x200 mm

|

2400x1000x200 mm

|

|

Main motor power

|

4 kw

|

4 kw

|

|

NW/GW

|

3400/3650 kg

|

3550/3850 kg

|

|

Overall dimensions (LxWxH)

|

2500x1060x2650 mm

|

2900x1060x2650 mm

|

|

Packing dimensions(LxWxH)

|

2600x1120x2600 mm

|

3000x1120x2600 mm

|

|

Standard Configuration

|

Optional Configuration

|

|

❶

Box table

❷ Drill chuck arbor ❸ Morse taper drill sleeve ❹ LED working lamp ❺ Coolant system ❻ Lifting motor ❼ Hydraulic motor ❽ Spindle protective cover ❾ Tools&tool-box, ❿ Operation manual |

❶

Rotation worktable

❷ Quick change collet ❸ Machine Vise ❹ Keyless drill chuck |

1. How can I choose the most suitable machines ?

Re: Please tell us your specifications ,we can choose the best model for you , or you can choose the exact model . You can also send us the products drawing ,we will choose the most suitable machines for you.

2. What's your main products of your company?

Re: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Manual Lathe Machine,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on.

3. What kinds of inspection you will do for each machine?

Re: For each assembly procedure, there is geometric accuracy test. After assembly, spindle accuracy will be tested by dynamical balance testing instrument; 3 axes accuracy will be tested by Ball bar. And laser interferometer to inspect positioning and repositioning accuracy. Then the inspection team will make full test before delivery and test piece will be done on each machine. Each workpiece will be inspected by CMM, so each machine performance can be checked and kept in record.

4. Can you supply turn-key solution?

Re: Of course, we have professional team of technical service & after sale service department, who can give you the perfect solution and meet your processing requirement. Besides, we also cooperated with professional fixture company and support with us.

5. What is the warranty time of machine?

Re: We have 14 months warranty after delivery. Within the warranty period, if there is any problem not caused by wrong operation, we will supply you the replacing parts from free. Even beyond the period, we will still supply the replacing parts with cost price.

6. What is the delivery time, and what is the package?

Re: Normally the delivery time is about 45-60 days. All our machines are packed with the seaworthy wooden case/pallet, also applied with anti rust measures in advance. View drawing together if any parts disassembled.

2. What's your main products of your company?

Re: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Manual Lathe Machine,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on.

3. What kinds of inspection you will do for each machine?

Re: For each assembly procedure, there is geometric accuracy test. After assembly, spindle accuracy will be tested by dynamical balance testing instrument; 3 axes accuracy will be tested by Ball bar. And laser interferometer to inspect positioning and repositioning accuracy. Then the inspection team will make full test before delivery and test piece will be done on each machine. Each workpiece will be inspected by CMM, so each machine performance can be checked and kept in record.

4. Can you supply turn-key solution?

Re: Of course, we have professional team of technical service & after sale service department, who can give you the perfect solution and meet your processing requirement. Besides, we also cooperated with professional fixture company and support with us.

5. What is the warranty time of machine?

Re: We have 14 months warranty after delivery. Within the warranty period, if there is any problem not caused by wrong operation, we will supply you the replacing parts from free. Even beyond the period, we will still supply the replacing parts with cost price.

6. What is the delivery time, and what is the package?

Re: Normally the delivery time is about 45-60 days. All our machines are packed with the seaworthy wooden case/pallet, also applied with anti rust measures in advance. View drawing together if any parts disassembled.

Hot Searches