- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 380V/415V

-

Power:

-

50KW

-

Dimension(L*W*H):

-

Width1700 x Depth8600 x Height2100 mm

-

Weight (KG):

-

3000

-

Product name:

-

Cyclone Automatic Powder Coating Spray Booth

-

Kinds of coating:

-

Powder coating

-

Usage:

-

This booth for powder spray use

-

Booth type:

-

Mono-Cyclone

-

Power supply:

-

Electric for spray paint booth

-

Nominal power:

-

50KW

-

Filter:

-

Polyester, 32pcs

-

Frequency:

-

50-60HZ

Quick Details

-

Machine Type:

-

Automatic Powder Coating Booth, Spray Booths, Painting Equipment, Coating Equipment

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLO

-

Voltage:

-

380V, 380V/415V

-

Power:

-

50KW

-

Dimension(L*W*H):

-

Width1700 x Depth8600 x Height2100 mm

-

Weight (KG):

-

3000

-

Product name:

-

Cyclone Automatic Powder Coating Spray Booth

-

Kinds of coating:

-

Powder coating

-

Usage:

-

This booth for powder spray use

-

Booth type:

-

Mono-Cyclone

-

Power supply:

-

Electric for spray paint booth

-

Nominal power:

-

50KW

-

Filter:

-

Polyester, 32pcs

-

Frequency:

-

50-60HZ

Product Description

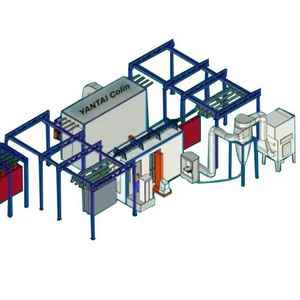

Fast Color Change Automatic Powder Coating Booth in Powder Spraying Line

This automatic powder coating booth constructed with plastic booth chamber and stainless steel cyclone, which is specially built for multi-color coating lines. As the booth wall is made of anti-static plastic it does not attract powders which minimizes powder accumulation on the surface. It is the best choice for quick color change and high powder recovery demands.

PP plastic automatic powder coating booth with mono cyclone recovery is the most efficient solution for color change demands in automatic production line. The plastic materials spray booth has obvious advantage to increase cleaning effiiency & reduce powder waste.

Details Images

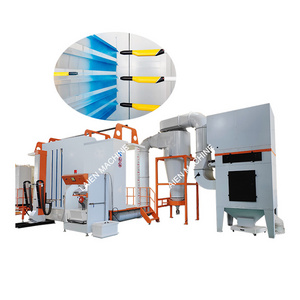

PP Plastic Powder Coating Cyclone Booth Features

1. Booth material is made anti-static engineering plastic, which is non-stick of powders, reduces powder waste and improve efficiency.

2. Mono cyclone achieves recycling efficiency up to 98%, a great saving of powders, a quick cleaning takes around 15 minutes.

3. With the discharge device of "large-diameter cyclone separator + after filter unit" makes the least powder accumulation and the most environmental-friendly emission.

4. There's air clean system continuously transports over sprayed powder from the booth floor, quickly recycling it back to the powder feed container.

Powder Coating Booth Floor Cleaning System

The bottom of the powder spray booth design can be selected based on workparts and recycling requirements.

Flap and air knife cleaning system

Mushroom head cleaning system

air knife cleaning system

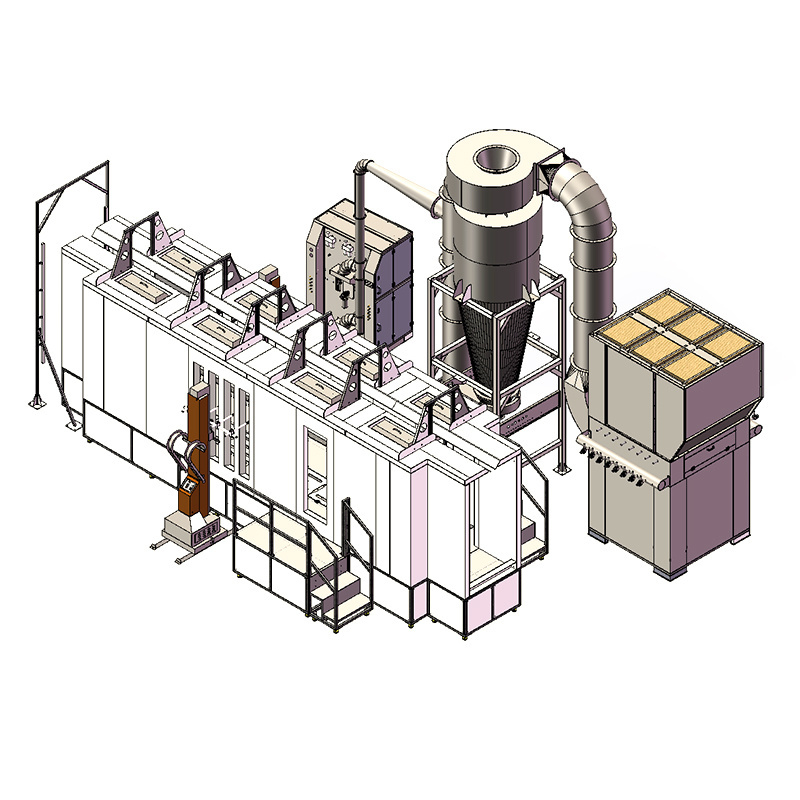

Product Paramenters

|

Booth Type

|

Automatic Type

|

|

Operator dimensions

|

Width1700 x Depth8600 x Height2100 mm

|

|

Weight

|

3000kg

|

|

Power supply

|

Electric

|

|

Nominal power

|

22kw

|

|

Voltage

|

380V/220V. customized as local.

|

|

Frequency

|

50-60Hz

|

|

Filters

|

Polyester

|

|

Filters count

|

32pcs (325*900)

|

|

Filters hang type

|

Rotary Wing, help filter cleaning

|

|

Filter cleaning system

|

Pneumatic

|

|

Booth Material

|

Wall:PVC; Floor PVC & Stainless Steel

|

|

Cyclone Material

|

Stainless Steel

|

|

Warranty

|

12 months

|

Related Products

Efficient Recycling Automatic Powder Coating System

Working with automatic powder coating reciprocator improves production efficiency, which allows custom design to select 2-24 pcs of auto spray guns to achieve any scale of production, one central control cabinet combines all gun controller for integrated operation, enbales to set parameters only at one host unit to control whole system.

Equipped with powder self-recycling feed center ensures maximum utilization of powder and least waste, so you no need to worry about the automatic powder recovery, filtering and powder return to the powder hopper.

Application

The automatic pp plastic powder coating booth is mostly used for the powder coating line spraying operation, and is used with the automatic spraying gun system, which is suitable for the batch spraying of auto parts, aluminum profiles, doors, windows and furniture, shelves and other workpieces.

Customer Feedback

Why Choose Us

Product packaging

Hot Searches