- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Depending on steel ladle Models

-

Power:

-

Depending on steel ladle Models

-

Dimension(L*W*H):

-

Depending on steel ladle Models

-

Weight (KG):

-

430

-

Product name:

-

Steel Foundry Iron Ladle

-

Capacity:

-

0.3-30 T/h

-

Usage:

-

Casting ,foundry, forge,pouring

-

Casting plant:

-

Cast Steel Casting Line

-

Feature:

-

Handle Pouring Metal Molten Liquid

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Cast Steel Ladle

-

Brand Name:

-

TZZJ

-

Voltage:

-

Depending on steel ladle Models

-

Power:

-

Depending on steel ladle Models

-

Dimension(L*W*H):

-

Depending on steel ladle Models

-

Weight (KG):

-

430

-

Product name:

-

Steel Foundry Iron Ladle

-

Capacity:

-

0.3-30 T/h

-

Usage:

-

Casting ,foundry, forge,pouring

-

Casting plant:

-

Cast Steel Casting Line

-

Feature:

-

Handle Pouring Metal Molten Liquid

Product Display&Details

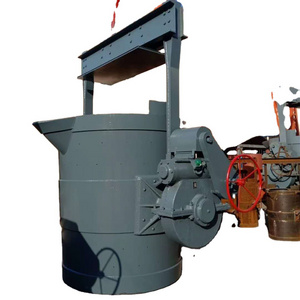

Foundry Pouring Ladle for Molten Steel

General Description

Foundry Pouring Ladle for Molten Steel is mainly used for pouring operation after receiving the liquid metal from the blast

furnace, then transported to the mould site to pouring.

It adopts worm and gear to operate flexibly and comfortably with two-way rotation and good reversibility. It is divided by manual and manual-electric dual operation. The manual operation is more convenient and electric operation is safe and labor-saving.

Feature of Foundry Pouring Ladle for Molten Steel

1) Reasonable choose the rotation center, convenient operation, basic can compound when pouring is finished .

2) Adopt double worm wheel pair transmission. Although manufacturing demand is high, but flexible transmission, two-way reversible.

3) Adding with special spray proof equipment, efficiently avoid iron water spraying into the gear box.

Foundry Pouring Ladle for Molten Steel is mainly used for pouring operation after receiving the liquid metal from the blast

furnace, then transported to the mould site to pouring.

It adopts worm and gear to operate flexibly and comfortably with two-way rotation and good reversibility. It is divided by manual and manual-electric dual operation. The manual operation is more convenient and electric operation is safe and labor-saving.

Feature of Foundry Pouring Ladle for Molten Steel

1) Reasonable choose the rotation center, convenient operation, basic can compound when pouring is finished .

2) Adopt double worm wheel pair transmission. Although manufacturing demand is high, but flexible transmission, two-way reversible.

3) Adding with special spray proof equipment, efficiently avoid iron water spraying into the gear box.

Details Images

|

Capacity (T)

|

|

0.3

|

0.5

|

0.75

|

1

|

1.5

|

2

|

2.5

|

3

|

||||||

|

Barrel outline (mm)

|

Top diameter

φ1( mm) |

520

|

606

|

643

|

722

|

830

|

897

|

943

|

1020

|

||||||

|

|

Bottom φ2 (mm)

|

468

|

551

|

574

|

652

|

750

|

810

|

853

|

920

|

||||||

|

|

Barrel height H (mm)

|

540

|

590

|

665

|

740

|

860

|

910

|

960

|

1035

|

||||||

|

|

Width A (mm)

|

1070

|

1136

|

1207

|

1260

|

1380

|

1437

|

1550

|

1621

|

||||||

|

|

Height B (mm)

|

1310

|

1349

|

1456

|

1479

|

1856

|

1890

|

2057

|

2131

|

||||||

|

Clearance height E (mm)

|

|

45

|

50

|

55

|

60

|

70

|

80

|

85

|

90

|

||||||

|

Patching thickness (mm)

|

Side wall b

|

35

|

40

|

45

|

50

|

60

|

60

|

65

|

90

|

||||||

|

|

Ladle bottom b1

|

45

|

50

|

55

|

60

|

70

|

75

|

80

|

70

|

||||||

|

Hand wheel radius R (mm)

|

|

200

|

200

|

250

|

250

|

350

|

350

|

350

|

350

|

||||||

|

Speed radio i

|

|

≤70

|

|

≤100

|

|

|

|

|

≤180

|

||||||

Hot Searches