- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Specially customized as clients' local power

-

Power:

-

2000 W

-

Dimension(L*W*H):

-

48" * 28" * 32"

-

Weight (KG):

-

160

-

Product name:

-

Plasma Magnetron Sputtering Coater

-

Keywords:

-

Magnetron Sputtering Coater

-

Input Power:

-

Single-phase 220 VAC 50 / 60 Hz

-

DC source:

-

500 W

-

RF source:

-

300 W power, 13.56 MHz frequency

-

Target size requirement:

-

2" diameter

-

Thickness range:

-

0.1 - 5 mm

-

Vacuum chamber:

-

300 mm Dia. x 300 mm Height

-

Sample holder size:

-

140 mm Dia. for. 4" wafer max

-

The holder temperature:

-

adjustable from RT to 500 °C max

Quick Details

-

Machine Type:

-

Plasma Magnetron Sputtering Coater, Pre-treatment Equipment, Coating Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MTI

-

Voltage:

-

Specially customized as clients' local power

-

Power:

-

2000 W

-

Dimension(L*W*H):

-

48" * 28" * 32"

-

Weight (KG):

-

160

-

Product name:

-

Plasma Magnetron Sputtering Coater

-

Keywords:

-

Magnetron Sputtering Coater

-

Input Power:

-

Single-phase 220 VAC 50 / 60 Hz

-

DC source:

-

500 W

-

RF source:

-

300 W power, 13.56 MHz frequency

-

Target size requirement:

-

2" diameter

-

Thickness range:

-

0.1 - 5 mm

-

Vacuum chamber:

-

300 mm Dia. x 300 mm Height

-

Sample holder size:

-

140 mm Dia. for. 4" wafer max

-

The holder temperature:

-

adjustable from RT to 500 °C max

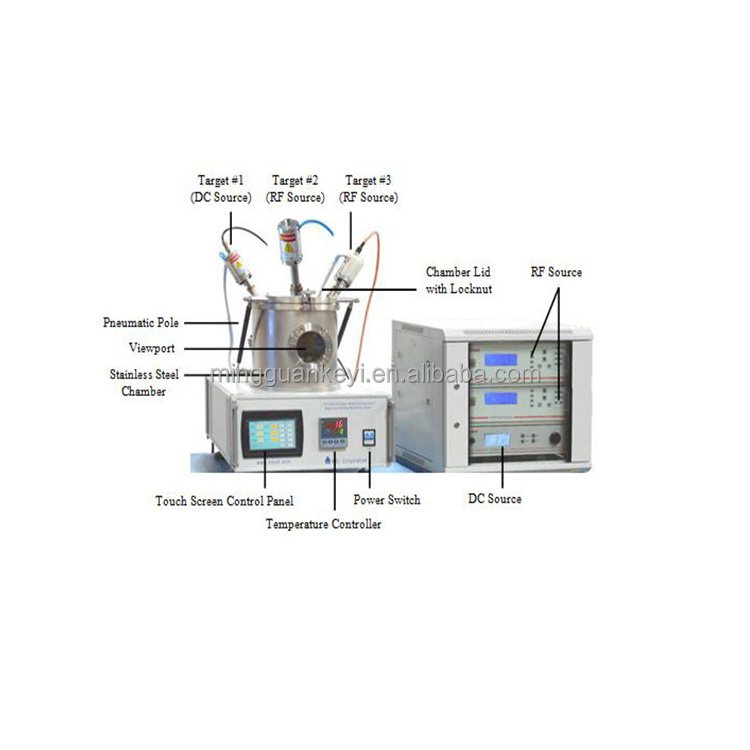

Plasma M agnetron Sputtering Coater with Three Sputtering Sources and RF/DC Power Supplies - VTC-600-3HD-LD

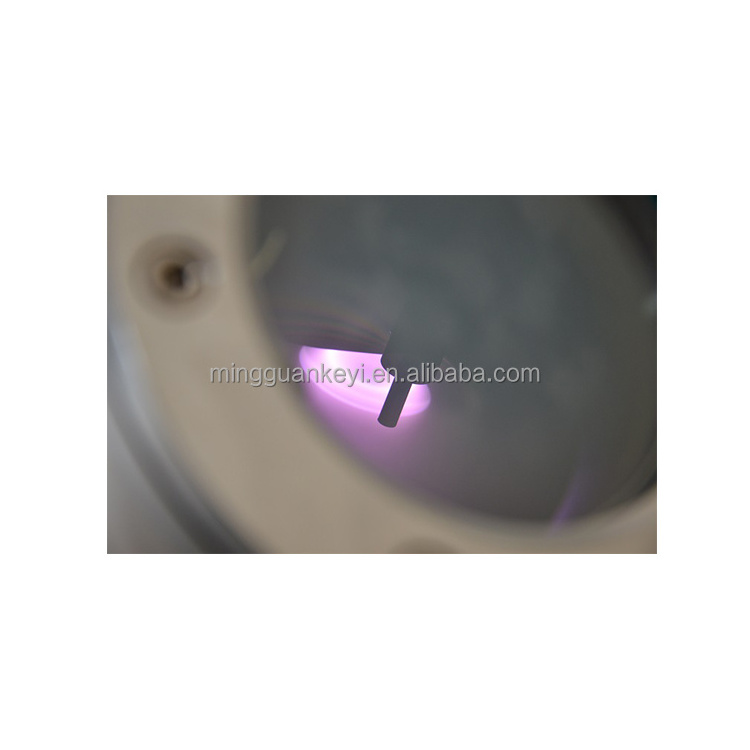

VTC-600-3HD-LD is a combinatorial plasma sputtering system with three 2“ magnetron sputtering sources and three RF/DC power supplies. Such a sputtering system is capable of co-sputtering up to three different target materials and creates various composition profiles across the substrate (e.g. ternary materials for Li-ion rechargeable battery) . This system is also suitable for sequential coating of multiple layer films such as ferroelectric, alloy, semiconductor, ceramic, dielectric, optical, oxide, hard, PTFE, etc.

SPECIFICATIONS

|

|

· Single-phase 220 VAC 50 / 60 Hz · 2000 W (including a vacuum pump and water chiller) |

|

· Three sputtering power sources are integrated into one control box o DC source: 500 W power for coating metallic materials o RF source: 300 W power, 13.56 MHz frequency for coating non-conductive materials |

|

|

|

· Three 2 inches sputtering heads with water cooling jackets and shutters are included (Click 1st pic from left) o Target size requirement: 2" diameter o Thickness range: 0.1 - 5 mm for both metallic and non-conductive targets (including the backing plate) · Customized coater: Two DC - One RF; Two RF - One DC; Three DC; Three RF. · Optional: 148 cm RF cable can be ordered at extra cost for the replacement |

|

|

· Vacuum chamber: 300 mm Dia. x 300 mm Height, made of stainless steel · Viewport: Two pieces of 100 mm Dia. glass. One fixed; one detachable for cleaning and replacement · Hinged type lid with pneumatic power pole allows easy target change |

|

|

· The sample holder is a rotatable and heatable stage made of the ceramic heater with copper cover · Sample holder size: 140 mm Dia. for. 4" wafer max · Rotation speed: 1 - 20 rpm adjustable for uniform coating · The holder temperature is adjustable from RT to 500 °C max (2 hr max) with accuracy +/- 1.0 °C via a digital temperature controller |

|

Gas Flow Control

|

·

Two precision mass flow controllers (MFC) are installed to allow inlet of two types of gases

o Flow rate: 0 – 200 mL/min & 0 - 100ml/min adjustable on the touch screen control panel · Air inlet valve is installed for vacuum release |

|

Vacuum Pump Station

|

· High-speed turbopump at speed 80L/S is combined with a two-stage mechanical pump (220 L/min) for max vacuum level and faster pumping speed · Standard vacuum level connected with chamber: < 4.0E-5 Torr. · Optional at extra cost · If choose a 150L/S high-speed turbopump , the vacuum can reach 10-6 torr with the chamber. · For the ultra-high vacuum up to 10^-7 torr, 700S/L turbopump is needed · 150L/S high-speed turbopump |

|

Water Chiller

|

· One digital temperature-controlled recirculating water chiller is included. o Refrigeration range: 5~35 °C o Flow rate: 16 L/min o Pump pressure: 14 psi |

|

Optional |

· Precise quartz Film Thickness Monitor is optional, which can be into the chamber to monitor coating thickness with an accuracy of 0.10 Å |

|

Overall Dimensions |

Lid closed: 48" × 28" × 32" Lid open: 48" × 28" × 37" |

|

Net Weight of Coater |

· 160 kg |

|

Shipping Weight & Dimensions |

· Total 3 Pallets o 365 lbs, 48" x 40" x 45" o 390 lbs, 48"x 40" x 49" o 210 lbs, 48" x 40"x 30" |

|

Compliance |

· CE approval |

|

Warranty |

· One year's limited warranty with lifetime support |

|

Application Note |

This coater may be placed into a standard glovebox with modification for thin-film battery research |