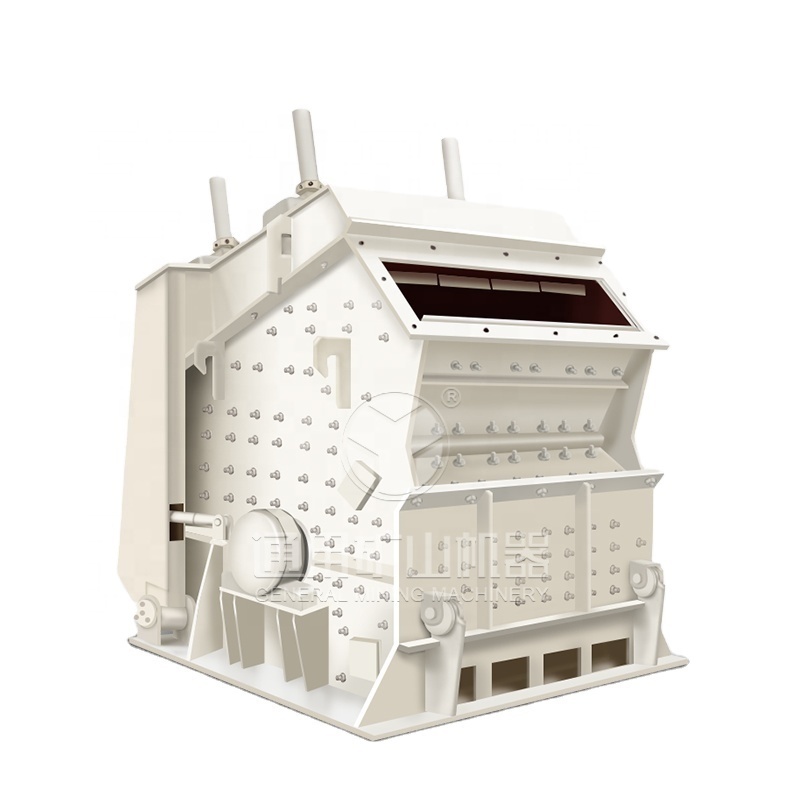

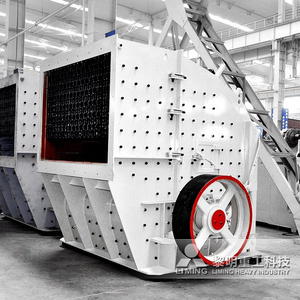

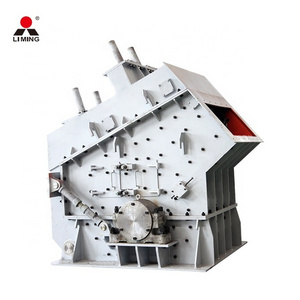

Impact Crusher is the newest generation product absorbing the advanced technologies at home and abroad and combining with the domestic gravel industry conditions. It adopts the newest manufacturing technology and unique structural design, and its final processed products are cubic, tension and crack free with very good overall shape. Moreover, it can crush various coarse, medium

and fine materials (tor example granite, limestone, concrete, etc.) with feed particle size less than 500mm and compressive resistance below 350MPa. The impact crusher with adjustable output size and diverse broken specifications is widely used for varies of industries including mining crushing, railway, highway,energy, cement, chemicals, construction and so on.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

9500 KG

-

Product name:

-

Impact Crusher Machine

-

Keyword:

-

Impact Crushing Machine

-

Name:

-

Crusher Stone Machine

-

The Machines classification:

-

Crushing Equipment

-

Raw material:

-

Stones Rocks Ores

-

Function:

-

Mining Crusher Equipment

-

After sale Service:

-

Video Support

-

Max feeding size:

-

500mm

Quick Details

-

Application:

-

mining used, Metallurgy

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TYM

-

Weight:

-

9500 KG

-

Product name:

-

Impact Crusher Machine

-

Keyword:

-

Impact Crushing Machine

-

Name:

-

Crusher Stone Machine

-

The Machines classification:

-

Crushing Equipment

-

Raw material:

-

Stones Rocks Ores

-

Function:

-

Mining Crusher Equipment

-

After sale Service:

-

Video Support

-

Max feeding size:

-

500mm

Products Description

Product Introduction

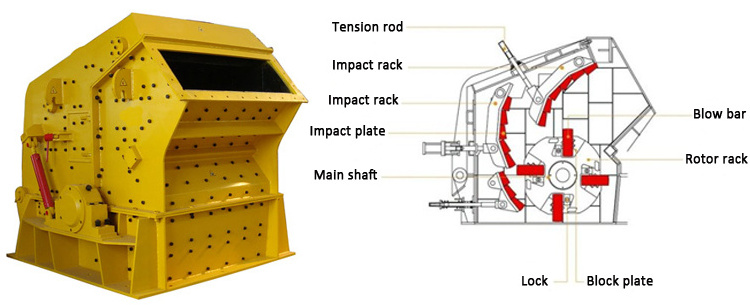

Working Principle:

When the hard rock counter-attacking crusher works, the electric motor drives the rotor where installed- hammers to rotate with high speed. When the materials get into the area which the hammers can de ettective, under the impact tunction of the hammers at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded trom the Impact liner to the area where the hammers can be ettective to be crushed again. The materials size trom big to small all will be crushed in the Impact chamber repeatedly. The process wont stop tIll the material are crushed to the required size and then will be discharged trom outlet.

Features

1.Large feeding size, high crushing chamber, high hardness of crushing materials and large size materials, less stone powder.

2. Adjustable breaking-plate and plate hammer gap brings about effective controllability discharge size and good particle shape.

3. Compact frame with high rigidity, rotor has a large moment of inertia.

1.Large feeding size, high crushing chamber, high hardness of crushing materials and large size materials, less stone powder.

2. Adjustable breaking-plate and plate hammer gap brings about effective controllability discharge size and good particle shape.

3. Compact frame with high rigidity, rotor has a large moment of inertia.

4. High chromium plate hammer with great impact resistance, abrasion resistance and impact.

5. No-board connection, easy maintenance and economic and reliable.

6. High crushing ratio, productivity and resistance of crusher parts and comprehensive benefits.

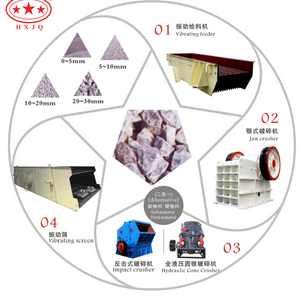

Gravel Production Line

The material is conveyed to the jaw crusher by vibrating feeder. After being crushed by the jaw crusher, it is sent to the vibrating screen through the conveyor belt. A part of the material that does not meet the requirements is crushed twice by the impact crusher, and then sent by the conveyor belt to the vibrating screen for screening and output.

Impact Crusher can crush various coarse, medium and fine materials (tor example granite, limestone, concrete, etc.) with feed particle size less than 500mm and compressive resistance below 350MPa. The impact crusher with adjustable output size and diverse broken specifications is widely used for varies of industries including mining crushing, railway, highway,energy, cement,chemicals, construction and so on.

Technical Parameter

|

Model

|

Rotor size(mm)

|

Feeding opening(mm)

|

Max feeding size(mm)

|

Production

capacity(t/h)

|

Power(kw)

|

Weight(t)

|

|

PF-1007

|

Φ1000x700

|

400x730

|

250

|

15-60

|

37-55

|

9.5

|

|

PF-1010

|

Φ1000x1050

|

400x1080

|

300

|

50-90

|

55-75

|

14

|

|

PF-1210

|

Φ1250x1050

|

400x1080

|

300

|

70-130

|

110-132

|

17

|

|

PF-1214

|

Φ1250x1400

|

400x1430

|

300

|

90-180

|

132-160

|

22

|

|

PF-1315

|

Φ1320x1500

|

860x1520

|

350

|

120-250

|

180-260

|

26

|

|

PF-1320

|

Φ1320x2000

|

860x2030

|

500

|

160-350

|

300-375

|

30

|

Recommend Products

Our Customers Site

Customize solutions according to customer requirements!

We are able to design and manufacture complete crusher plants with capacity from 30tph to 500tph, and to provide optimum and most economical solutions according to customers' requirements on stone specifications, output, application, etc.

This is our stone production line in Indonesia!

The customer's requirements:

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

Equipment configuration: 2xZSW490*130 vibrating feeder, 2 PE750x1060 jaw crusher, 2xPYD2200 cone crusher, 2x3YZS2460 vibrating screen, a VSI1140 sand making machine.

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

This is our stone production line in Philippine!

The customer's requirements:

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

This is our stone production line in Bolivian!

The customer's requirements:

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

This is our stone production line in Vietnam!

Raw material: Barite, capacity: 40 tons/hour, finished products: 0-8mm, 8-15mm, 15-25mm.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Hot Searches