- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Hydraulic

-

Certification:

-

CE

-

After-sales Service Provided:

-

Free spare parts, No after-sales service, Video technical support, Online support

-

Name:

-

WC67K roll bending machine

-

WC67K roll bending machine:

-

Hydraulic drive

-

Usage:

-

Metal Sheet Bending/Construction Pipe

-

poles other usage::

-

telecommunication poles

-

Processing material:

-

Steel Aluminum

-

Using:

-

Square steel I-beam Rectangle Etc.

-

Material Processed:

-

Mild Steel Sheet Plate bending

-

process materials:

-

stainless steel bending

-

Ambient temperature::

-

55℃ ~+45℃

-

Humidity::

-

20% - 75% non-condensing

-

Weight:

-

360T

Quick Details

-

Nominal Pressure (kN):

-

30000

-

Length of Working Table (mm):

-

14000

-

Place of Origin:

-

Liaoning, China

-

Power:

-

Hydraulic

-

Certification:

-

CE

-

After-sales Service Provided:

-

Free spare parts, No after-sales service, Video technical support, Online support

-

Name:

-

WC67K roll bending machine

-

WC67K roll bending machine:

-

Hydraulic drive

-

Usage:

-

Metal Sheet Bending/Construction Pipe

-

poles other usage::

-

telecommunication poles

-

Processing material:

-

Steel Aluminum

-

Using:

-

Square steel I-beam Rectangle Etc.

-

Material Processed:

-

Mild Steel Sheet Plate bending

-

process materials:

-

stainless steel bending

-

Ambient temperature::

-

55℃ ~+45℃

-

Humidity::

-

20% - 75% non-condensing

-

Weight:

-

360T

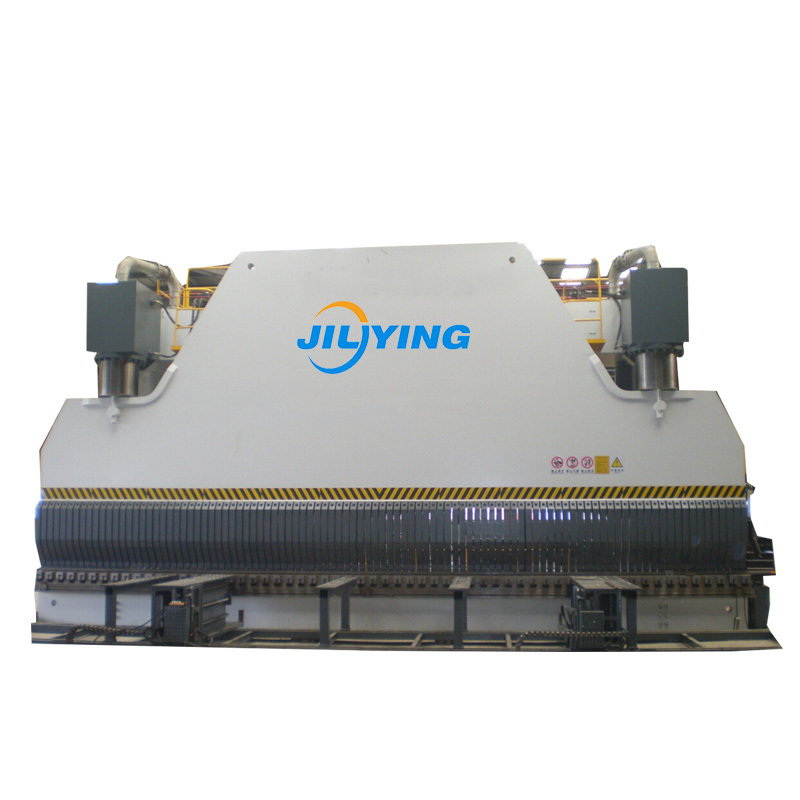

High-Performance JCO WC67Y hydraulic press break machine for the manufacture of metal profiles

Product Description

1.1, Equipment is whole steel welded structure using screw connection, eliminate stress, with high strength, good rigidity, and easy to disassemble and transport.

1.2, Equipment weldseam without undercuts, pores, cracks and other welding defects, the outer surface of the weld grinding smooth, no spatter, the whole flat smooth surface without bump, steel or cover the joints neat, straight without obvious Slot.

1.3, The device is hydraulic on transmission, the two cylinders (Y1, Y2 axis) can work simultaneously, workbench and the slider to maintain parallel. The two ends of the machine are equipped with two gratings to detect the distance between the slide and the worktable. The grating ruler is connected with the workbench so that the post deformation will not affect the positioning accuracy. The position data is immediately fed back to the numerical control system so that it can output Servo valve control signal.

1.4, The slider and the hydraulic cylinder connection using advanced connection, slider-oriented system uses advanced guidance system, the slider run more stable and more reasonable. The slider can be tilted relative to the work table, can be tilted about 25mm (slider can be tilted ≤ 0.1 °).

|

Name |

Specification |

Unit |

|

|

Nominal Pressure |

30000 |

KN |

|

|

Length of worktable |

14000 |

mm |

|

|

Width of worktable |

800 |

mm |

|

|

Effective internal spacing |

12500 |

mm |

|

|

Width of side-throat |

1500 |

mm |

|

|

Slide stroke |

400 |

mm |

|

|

Maximum open height |

1800 |

mm |

|

|

Main cylinder quantity |

2 |

individual |

|

|

Main cylinder diameter |

Φ850 |

mm |

|

|

Main cylinder working pressure |

26.5 |

MPa |

|

|

Speed of slide |

Speed of driven |

50 |

mm/s |

|

Speed of working |

4 |

mm/s |

|

|

Speed of return |

40 |

mm/s |

|

|

Main motor power |

2×75 |

KW |

|

|

Overall size |

Length |

14000 |

mm |

|

Width |

3800 |

mm |

|

|

Height on ground |

8000 |

mm |

|

|

Depth under ground |

5900 |

Mm |

|

|

Diameter |

Min-max |

16inch-30inch |

|

Want to know this JCO Press Pipe Marking Machine more information! Contact us>>

dis he d end forming machineCompany specializing in tank making machinery equipments,such as dish end machine,triming cutting machine,Necking machine, Longitudinal seam welding machine,Circular Seamwelding machine,cutting machine,bending machine,rolling machine etc.

Want to know other machines related to this JCO Pipe Marking Machines! More>>