- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HIGEE

-

Dimension(L*W*H):

-

2200*2100*2200MM

-

Weight:

-

4500 KG, 500 kg

-

Name:

-

Test Tube Filling Capping Machine Manufacturer

-

Bottle type:

-

2-250 ml

-

Filling material:

-

SS 304

-

filling speed:

-

1000-7000 bph

-

filling station:

-

1 pcs - 4 pcs

-

filling method:

-

ceramic or peristaltic pump

-

filling volume error:

-

0.5

-

power:

-

3ph, 380V/50Hz, 2KW

-

machine size:

-

1500 * 1000 * 2250 mm

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

liquid

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HIGEE

-

Dimension(L*W*H):

-

2200*2100*2200MM

-

Weight:

-

4500 KG, 500 kg

-

Name:

-

Test Tube Filling Capping Machine Manufacturer

-

Bottle type:

-

2-250 ml

-

Filling material:

-

SS 304

-

filling speed:

-

1000-7000 bph

-

filling station:

-

1 pcs - 4 pcs

-

filling method:

-

ceramic or peristaltic pump

-

filling volume error:

-

0.5

-

power:

-

3ph, 380V/50Hz, 2KW

-

machine size:

-

1500 * 1000 * 2250 mm

Disposable consumables Test tube filling capping labeling machine

Application

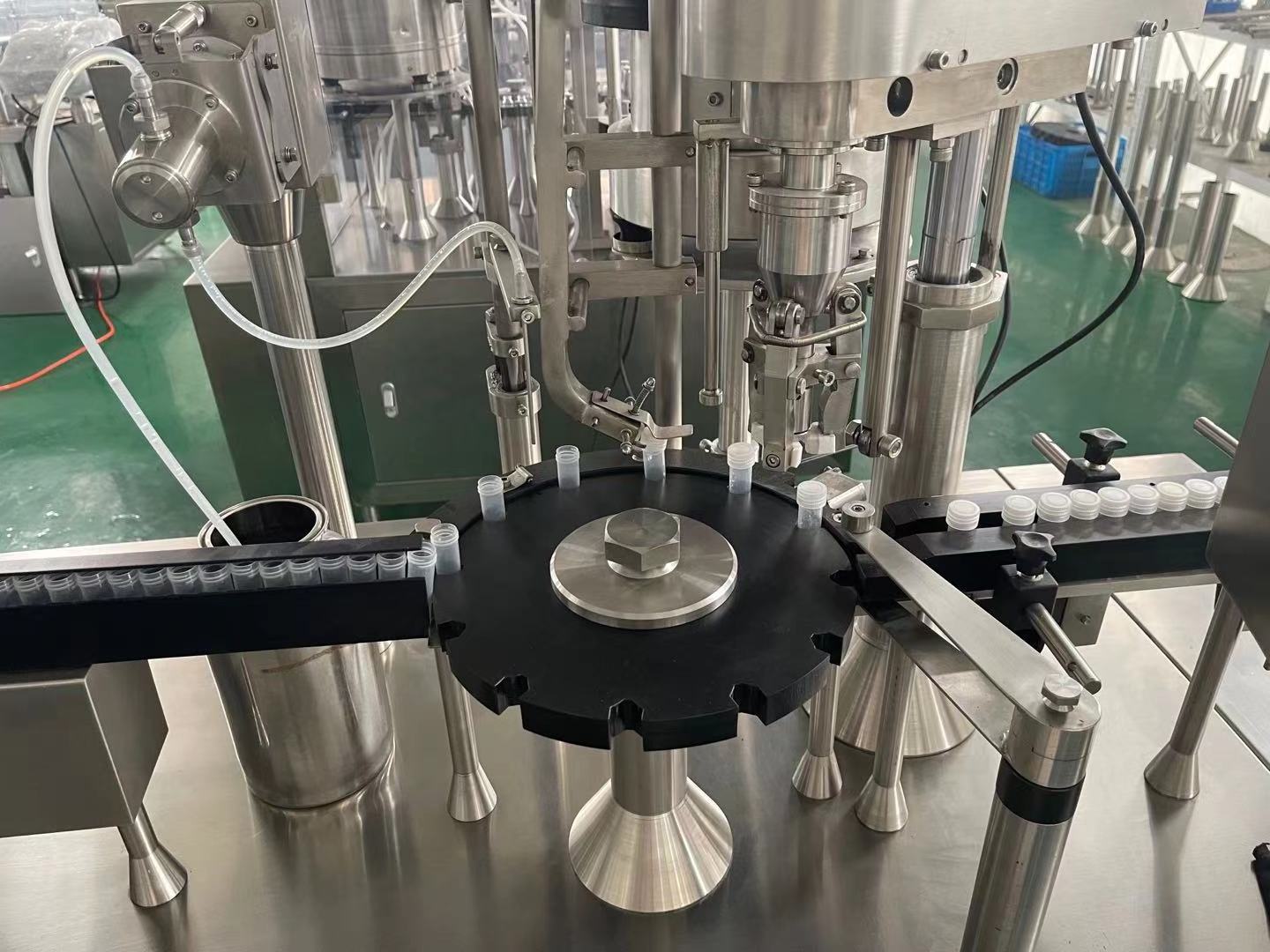

this is automatic pla s tic tube filling, screw capping and labeling of plastic tube reagents. This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design; working table is protected by stainless steel material, and the whole machine meets GMP requirements.

Working precess

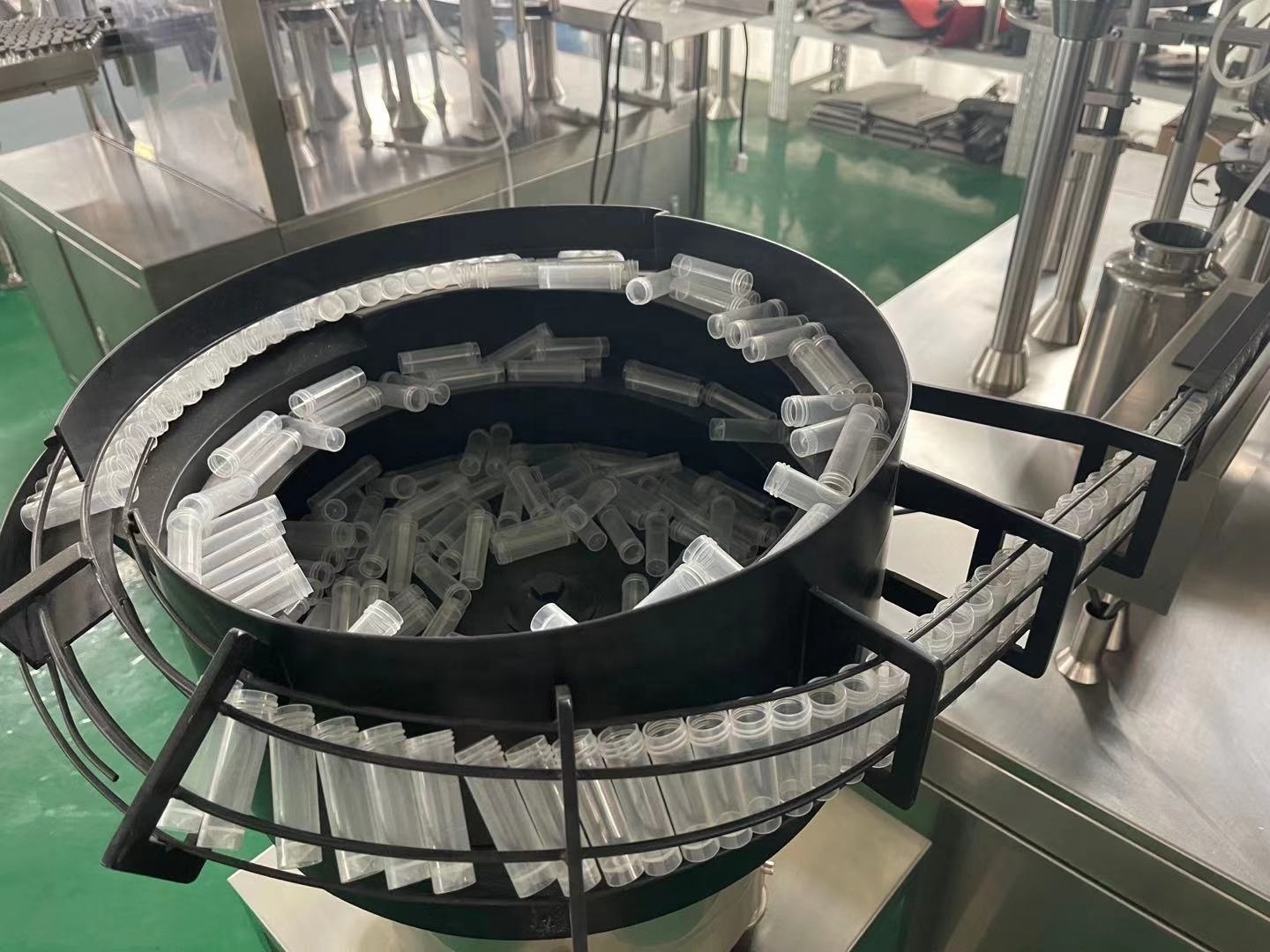

put bulk of test tubes into arranging hopper, then slim tube will be moved along the chute and enter into aliquots disk and will rotate together with this disk intermittently, tube will in turn throught filling station,cap-placing and capping station, in filling station, the ceramic pump will fill solution into the tube, then filling liquid into the tube after that capping with screw cap by automatically.

Feature:

1.Application range:plastic vial, kinds of special plastic bottles.

2.Install with imported ceramic pump, has very low error of filling volume.

3.adopt vibration hopper to arranging and feeding tubes, avoid the slender type tube falling over.

4. this equipment includeds bottle arranging -filling -capping station.

5.can install with A class LAF purifying hood for protection internal production area (optional)

6. it's widely used in diagnostic reagent field, also can custom equipment according to user filling sealing requirements

Tecnical parameters:

| Application for |

2-20ml vial |

| Yield capacity |

50-120pcs/m |

| Filling station |

1-2 pcs |

| Filling method |

ceramic pump |

| Filling accuracy |

≤±0.5% |

| Stoppering qualifcation rate |

≥99.5% |

| Power supply |

380V 50Hz,1.5kw |

| Dimension |

1400*900*2250mm |

| Weight |

500kg |

the machien pictures :