Liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol,plant protein drink,etc.); Barrel filling line(1-5 gallon); Water treatment machines, Labeling & packing machines, Semiautomatic/Full automatic PET Bottle blowing machines, and Injection molding machines. Labeling machine, Bottle shrink packing machine , Carton packing machines ,Conveyor system , Juice processing system , Sterilizer and so on.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

High

-

Voltage:

-

220V/380V(by order)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V PACK

-

Dimension(L*W*H):

-

3100*2450*2800mm

-

Weight:

-

2600 KG

-

Filling material:

-

Flowing Liquid

-

Product name:

-

Oil Filling Machine

-

Capacity:

-

1000-30000bph

-

Key words:

-

Oil Filling Production Line

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 6000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Other

-

Filling Material:

-

Other, Oil

-

Filling Accuracy:

-

High

-

Voltage:

-

220V/380V(by order)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V PACK

-

Dimension(L*W*H):

-

3100*2450*2800mm

-

Weight:

-

2600 KG

-

Filling material:

-

Flowing Liquid

-

Product name:

-

Oil Filling Machine

-

Capacity:

-

1000-30000bph

-

Key words:

-

Oil Filling Production Line

Our products

SUITBLE PRODUCT

Edible Oil .

Suitable

:

Edible Oil

Lubricating Oil +Special Solvents .etc

Bottle Material : PET / PE / Glass / Metal

Lubricating Oil +Special Solvents .etc

Bottle Material : PET / PE / Glass / Metal

Bottle Type :

Round / Square / Unique

Cap :

Press cap

Label :

Sticker Label / Shrink

Detergents.

Suitable :

detergent,shampoo,dishwasher,liquid soap etc

Bottle Material : PE Bottle

Bottle Type : Round / Square / Unique

Bottle Material : PE Bottle

Bottle Type : Round / Square / Unique

Cap :

Screw cap

Label : Sticker Label

Label : Sticker Label

Corrosive Liquid.

Suitable :

bleach,clorox, toilet cleaner .

Bottle Material : PP Bottle

Bottle Type : Round / Square / Unique

Cap : Screw cap

Label : Sticker LabelCorrosive Liquid.

bleach,clorox, toilet cleaner .

Bottle Material : PP Bottle

Bottle Type : Round / Square / Unique

Cap : Screw cap

Label : Sticker LabelCorrosive Liquid.

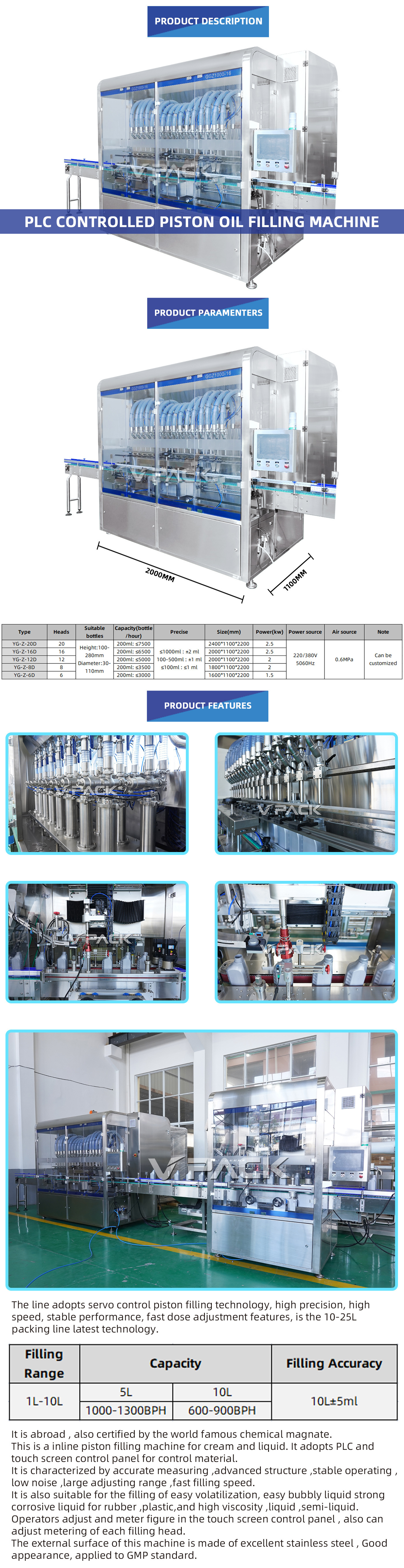

Automatic Piston Oil Filling Machine.

This type machine is suitable for filling viscous,inviscid and corrosive liquid.It's widely applied in plant oil,chemical

liquid,and daily chemical industry.It adopts linear type filling,electromechanical&instrucmental intergration controlling.It's simple and rapid for changing the varieties with unique design and superior capability.It's appearance accords with the international machinery concept. Germay SIEMENS PLC and touch screen control make it intelligentize protection function.Vacuum anti-dropping device ensures no leaking situation in production.Electrinic ajusting for volume system,frequency control and photoelectric detecting system(Germany TURCK brand) are applied in this machine.

liquid,and daily chemical industry.It adopts linear type filling,electromechanical&instrucmental intergration controlling.It's simple and rapid for changing the varieties with unique design and superior capability.It's appearance accords with the international machinery concept. Germay SIEMENS PLC and touch screen control make it intelligentize protection function.Vacuum anti-dropping device ensures no leaking situation in production.Electrinic ajusting for volume system,frequency control and photoelectric detecting system(Germany TURCK brand) are applied in this machine.

|

Containers and Specifications

|

|

|

|

|

||||

|

Project Name:Automatic Piston/Flowmeter Filling Machine

|

|

|

|

Oil and Fat Products

|

||||

|

Bottle Material

|

Bottle Shape

|

Filling Range

|

Filling Heads

|

Production Capacity

|

||||

|

PET/PP/PE/Glass/Metal

|

Round/Square/Unique Shape

|

200ml-6000ml

|

4-16

|

700-4000BPH

|

||||

|

Filling Valve

|

Each filling valve is controled by servo motor,realizing segmented high-and low-speed control;vacuum resorption devices without leakage

|

|

|

|

||||

|

|

|

|

|

|

||||

|

Cap closing method

|

applicability for both crowning and capping,mechanical instant sealing or servocontrolled sealing

|

|

|

|

||||

|

|

|

|

|

|

||||

|

Bottle components

|

rapid replacement without tools,such as star wheels for bottle infeed and outfeed,and bottle neck clamps

|

|

|

|

||||

|

Filling precision

|

limit deviation:±2-3g standard deviation:1.5

|

|

|

|

||||

|

User Ambient Conditions

|

|

Temperature:10~40℃;Humidity:No dew

|

|

|

||||

|

|

|

|

|

|

||||

|

User Electrical Supply Specification

|

|

Voltage:380V±5%,3phase;Frequency:50HZ±1%

|

|

|

||||

transduction and pneumatic action.

This machine is suitable for filling viscous and corrosive liquid,it is widely applied in plant oil,chemical liquid,and daily chemical industry.

|

Model

|

GY12-4

|

GY18-6

|

GY24-8

|

GY32-10

|

|||

|

Capacity 500ml<b/h>

|

3000

|

5000

|

7000

|

10000

|

|||

|

Bottle Applicant

|

150-340mm

|

|

|

|

|||

|

Power<W>

|

2.2

|

3.84

|

3.84

|

5.6

|

|||

|

Overall Size<mm>

|

2000*1670*2350

|

2070*1970*2350

|

2465*2170*2350

|

3000*2570*2350

|

|||

|

Total Weight<kg>

|

2500

|

3000

|

4000

|

5000

|

|||

|

Suitable Cap

|

Diameter50-110mm

|

|

|

|

|||

|

Filling Pressure

|

0.2-0.3Mpa

|

|

|

|

|||

|

Filling Temperature

|

Room Temperature

|

|

|

|

|||

Semi-automatic Oil Filling Machine.

This type of machine is widely uesd in filling of viscous liquid such plant oil chemicals.Its

fealures are flexible and can be used anywhere.

Its design is distinct.It has many advantages.

It has applied imported Germany SIEMENS controller.

Its design is distinct.It has many advantages.

It has applied imported Germany SIEMENS controller.

|

Parameter

|

Unit

|

Unit

|

Unit

|

|

No. of Head

|

2

|

1

|

1

|

|

Filling Weight

|

20ml-10L

|

5-50kgs

|

50-200kgs

|

|

Entrance of pressure

|

2-2.5Bar

|

2-2.5Bar

|

3Bar

|

|

Productivity

|

400-500B/HOUR<5KGS>

|

120-200B/HOUR<20KGS>

|

40-60B/HOUR<200KGS>

|

|

Filling tolerance

|

≤0.3%

|

≤0.3%

|

≤0.5%

|

|

Power

|

380/220V 90W

|

220V±10% 0.1KW

|

220V±10% 0.1KW

|

|

Gas pressure

|

0.55-0.8Mpa

|

0.55-0.8Mpa

|

0.55-0.8Mpa

|

|

Air consumption

|

0.3m³/min

|

0.3m³/min

|

0.3m³/min

|

Detail for machine parts

Special oil filling machine piston cylinder

As shown in the pictures new cylinder liner in the piston bottom will be much more fexible than the unable disassembled and washed traditional cylinder, you can see touch screen and separate piston and cylinder liner, in order to easier cleaning for residual materials, easy choose different mode for different material or color.

Commonly used oil filling valve

1.widely used in filling machinery,especially suitable for filling viscous material.

2.Fast filling speed, prevision and stability

3.Delicate and small,esay for arrangement of pipe arrangement

4.special seal design at the bottom of the filling nozzle, filling without dripping

5.chamfering structure on the bottom of filling head, with orientation effect and submersible filling

2.Fast filling speed, prevision and stability

3.Delicate and small,esay for arrangement of pipe arrangement

4.special seal design at the bottom of the filling nozzle, filling without dripping

5.chamfering structure on the bottom of filling head, with orientation effect and submersible filling

Auxiliary equipments

Twisting Capping Machine.

This machine is suitable for glass bottle and plastic bottle ,screw/thread caps twisting ,it can used in a wide range of bottles(with differen top diameter ), by adjust the machines but not change parts. Also, the speed is quicker than disc capper.

Advantage : for different size bottles and caps, it do not need to change any part. The machine can be adjust from right & left, up and down, very convenience.

Advantage : for different size bottles and caps, it do not need to change any part. The machine can be adjust from right & left, up and down, very convenience.

Automatic Double Side labeling machine.

1/Adopt mature PLC control technology, make the machine stable and high-speed

2/Can be suitable for square/round/oval flat bottles at the same time

3/Use touch screen control system, make operation simple, practical and efficient

4/Screw adjust the suppression mechanism, high accuracy

5/Tranparent label sensor is for optional

6/Can be customized according to your requirement

2/Can be suitable for square/round/oval flat bottles at the same time

3/Use touch screen control system, make operation simple, practical and efficient

4/Screw adjust the suppression mechanism, high accuracy

5/Tranparent label sensor is for optional

6/Can be customized according to your requirement

PET Bottle Making Machine.

1/Stable performance with advanced PLC.

2/No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

3/Strong clamping force with high pressure lock the mold.

4/Two ways of operating: automatic and manual.

5/Safe,reliable and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

6/Low cost,high efficiency,easy operation,easy maintenance,etc,with automatic technological process.

2/No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

3/Strong clamping force with high pressure lock the mold.

4/Two ways of operating: automatic and manual.

5/Safe,reliable and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

6/Low cost,high efficiency,easy operation,easy maintenance,etc,with automatic technological process.

Related products

Sticker Labeling Machine

* Various product infeed systems are available that provide precise product spacing and orientation. It can be used stand alone or integrated in-line and matching filling equiment speeds.

* Heavy-duty construction utilizes oversized drive components combined with an aluminum and stainless steel base frame for years of dependable service.

* Advanced high torque micro-stepping driven applicators include ratio-offset and speed-following capability for accurate and reliable application of a wide variety of label materials.

* Designed for the application of front and/or back panel labels with the capability to label containers that are round, square, oval or rectangular

* Heavy-duty construction utilizes oversized drive components combined with an aluminum and stainless steel base frame for years of dependable service.

* Advanced high torque micro-stepping driven applicators include ratio-offset and speed-following capability for accurate and reliable application of a wide variety of label materials.

* Designed for the application of front and/or back panel labels with the capability to label containers that are round, square, oval or rectangular

This packing machine is suitable for PE, PP, PET bottles.The machine occupies a small area and speed is fast. Its own conveyor

belt can be connected to the production line. The packaging size can be customized according to the actual production needs of

customers, with a certain range of adjustment, PLC control system and human-machine interface, easy to operate, and solve the

packaging problems of plastic products for customers all over the world.

Our Company

Our Suppliers

Our Service

Factory Design Service

Bottle Design Service

Pre-Sales Service

* Inquiry and consulting support.

* Machine testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Sales Manager : Jack Shao

Responsible for the project

:

CO2 & Fiber Laser Printer, Water purificaiton system, Water filling machine, Juice hot filling machine, 5 gallon plant etc, Bottle blower...all kind of machine after-service.

Responsible for the market :

Jordan, Nigeria, Peru, Dubai, Morocco, Yemen, etc.

Recommend Products

Hot Searches