- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

wanrooetech

-

Application:

-

Plastic Recycling

-

Production Capacity (kg/h):

-

100 - 3000

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

4000*1800*3800mm

-

Power (kW):

-

150

-

Weight (T):

-

3

-

Product name:

-

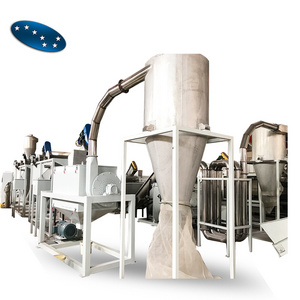

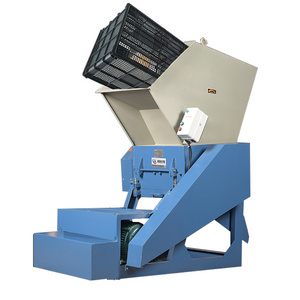

PET Bottle Washing Line Plastic Washing line

-

Motor power:

-

3kw

-

material:

-

stainless steel

-

speed:

-

30rpm/min

-

brand:

-

wanrooetech

-

power:

-

380V 50Hz

-

Color:

-

Customer Choice

-

Weight:

-

6000 KG

-

Power(W):

-

156-420KW

-

Production Capacity:

-

300- 2000 Kg/h

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

3000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

wanrooetech

-

Application:

-

Plastic Recycling

-

Production Capacity (kg/h):

-

100 - 3000

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

4000*1800*3800mm

-

Power (kW):

-

150

-

Weight (T):

-

3

-

Product name:

-

PET Bottle Washing Line Plastic Washing line

-

Motor power:

-

3kw

-

material:

-

stainless steel

-

speed:

-

30rpm/min

-

brand:

-

wanrooetech

-

power:

-

380V 50Hz

-

Color:

-

Customer Choice

-

Weight:

-

6000 KG

-

Power(W):

-

156-420KW

-

Production Capacity:

-

300- 2000 Kg/h

100-3000kg/h PET Bottle Washing Line Plastic Washing line PET Bottle Recycling Machine

In order to better give you professional answers, when sending the inquiry, please describe your parameters or technical requirements (such as: processing materials, output size, capacity, etc.) and attach your contact information (such as phone number, e-mail, facebook, whatsapp, wechat, etc.)

|

Input capacity |

500kg/h |

1000 kg/h |

2000 kg/h |

|

Workshop(M*M*M) |

42 (L)×10(W)×6(H) |

55(L)×15(W)×6(H) |

70(L)×18(W)×6(H) |

|

Ancillary staff |

6Persons |

8 Persons |

12 Persons |

|

Installation power |

156KW |

307KW |

420KW |

|

Water Consumption: |

2Ton/h |

3.5Ton/h |

5 Ton/h |

|

Final product |

Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |