High Lift Time

High Efficiency

High

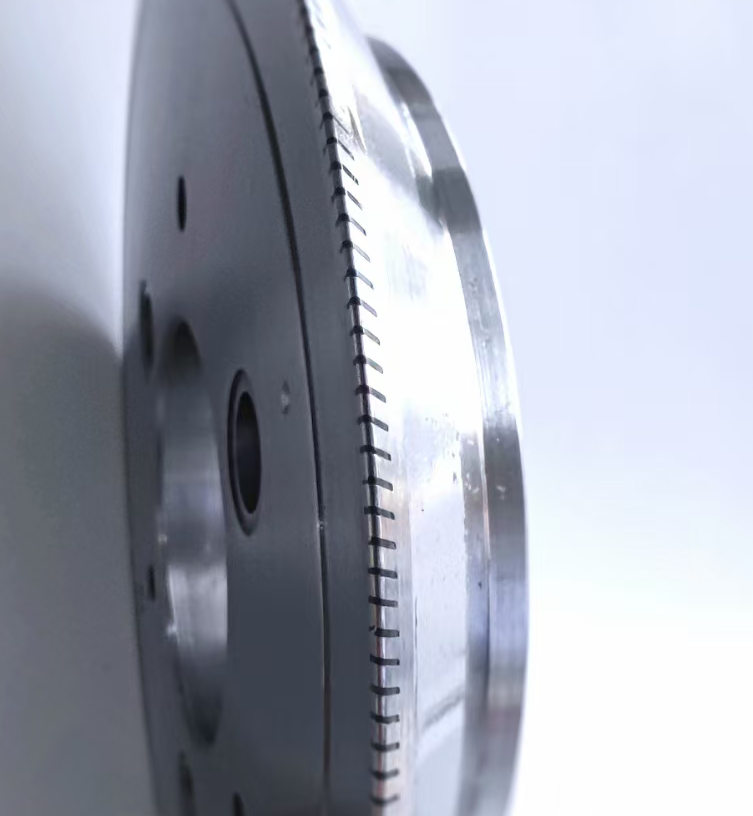

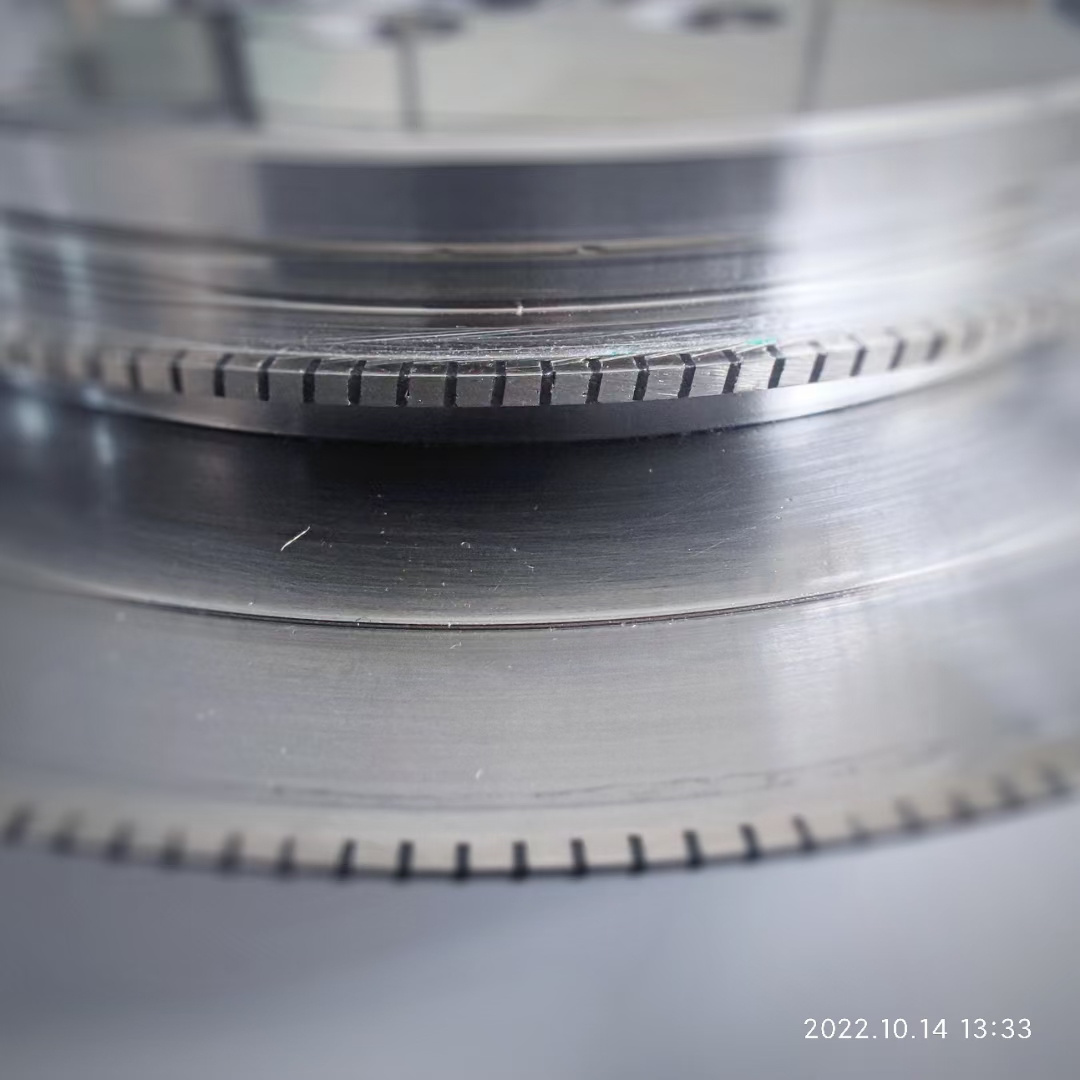

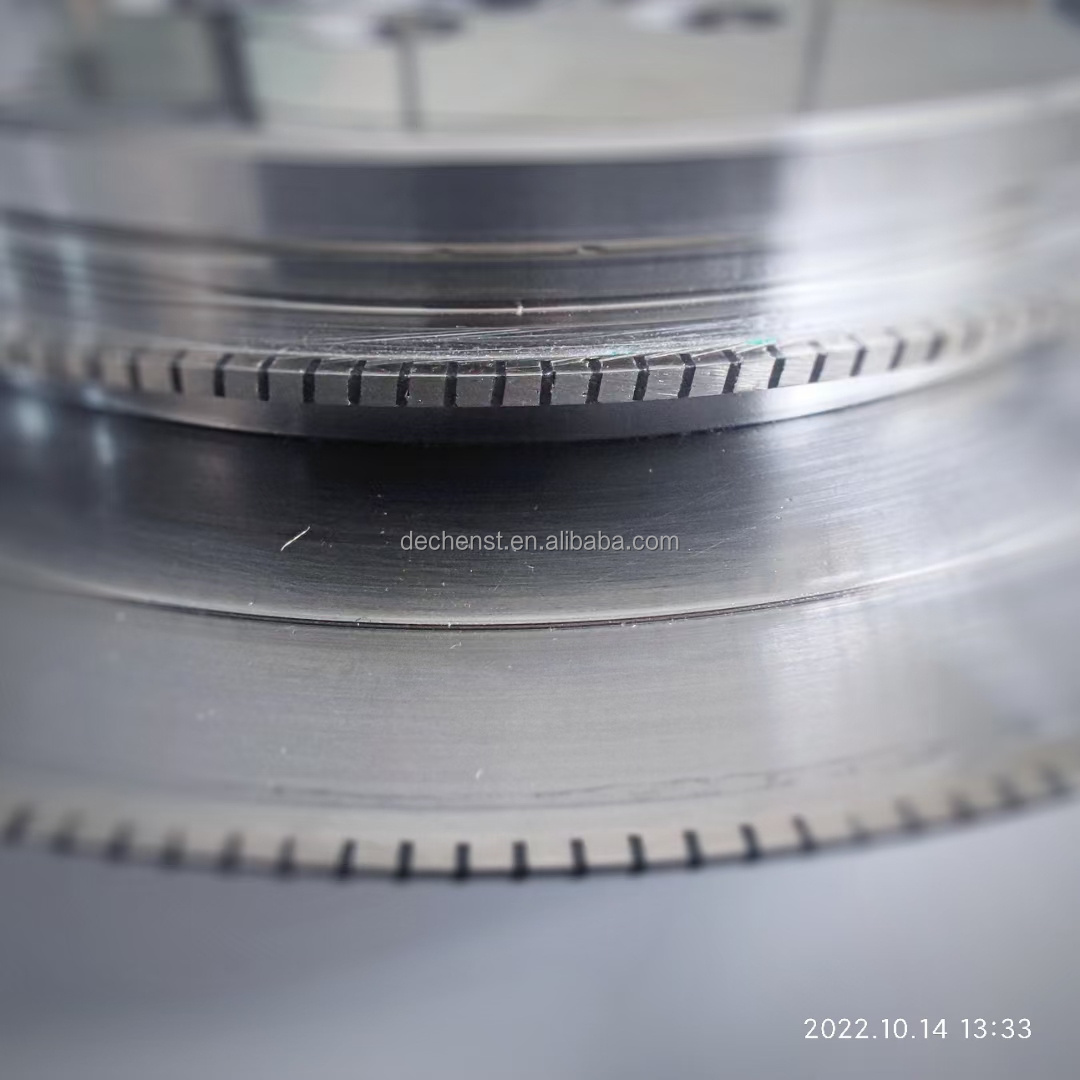

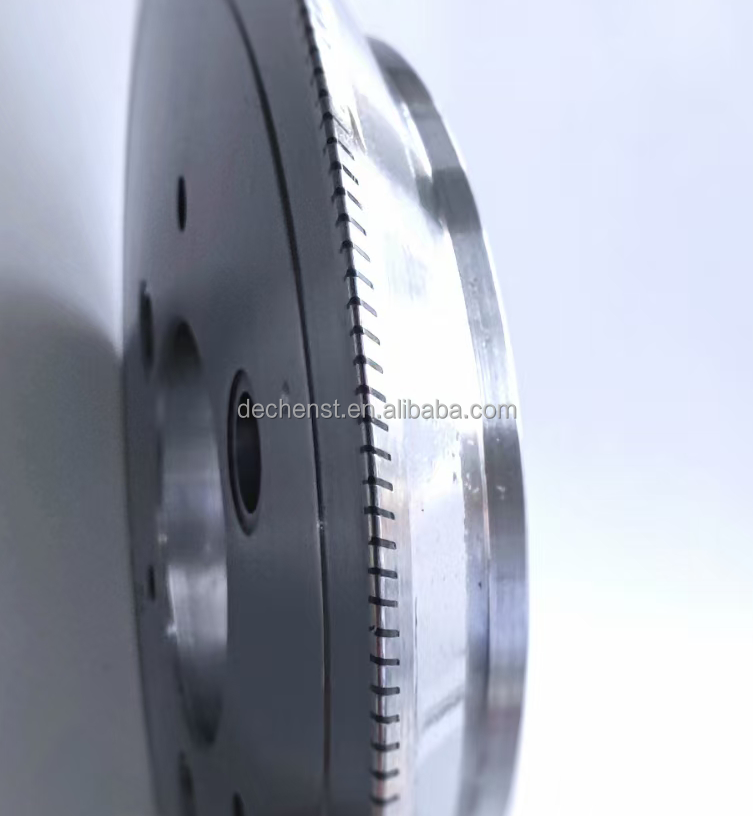

Quality

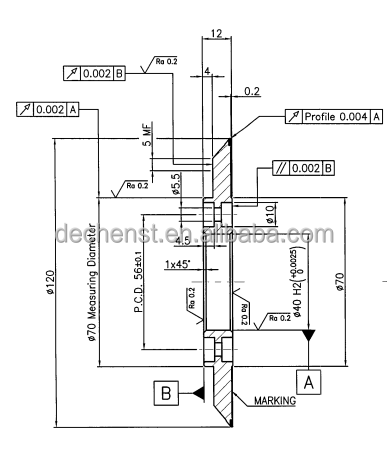

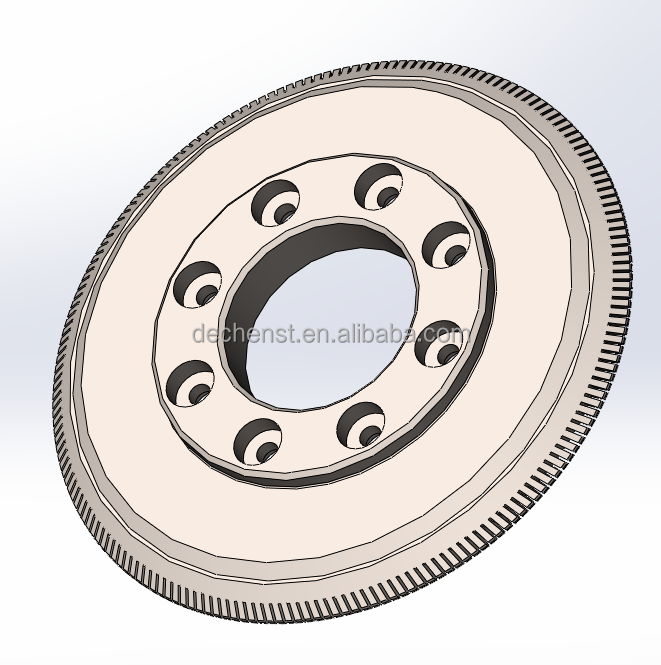

Support customization with drawing