- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jopar

-

Voltage:

-

380/415/420/440V

-

Power:

-

7.5KW+7.5KW

-

Dimension(L*W*H):

-

21.5*1.1*1.5M

-

Weight:

-

6500 kg

-

Diameter:

-

8-51mm

-

Thickness:

-

0.3-2.2mm

-

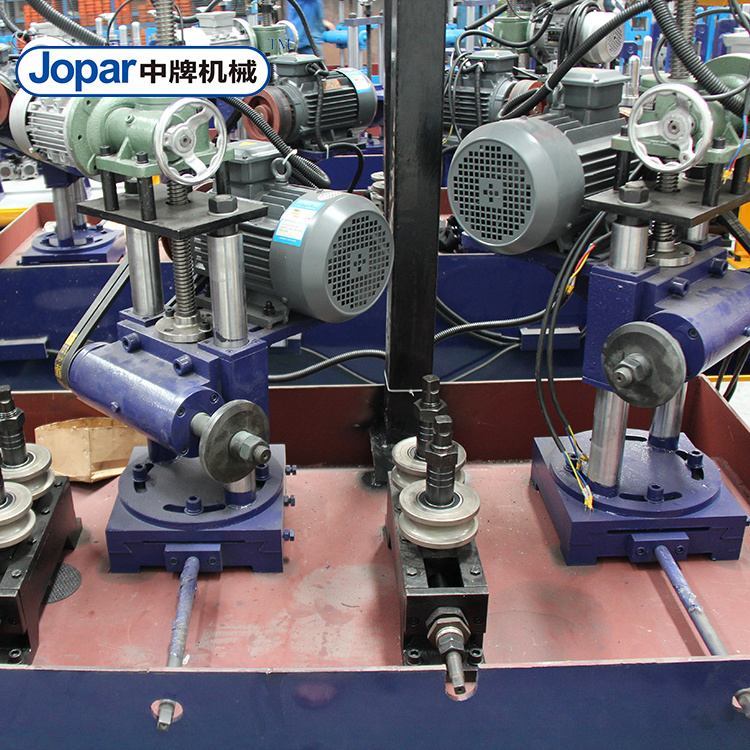

Vertical shaft:

-

25mm

-

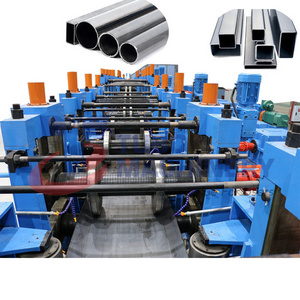

Pipe shape:

-

Round / Square / Rectangle / Oval

-

Welding type:

-

Argon Welding

-

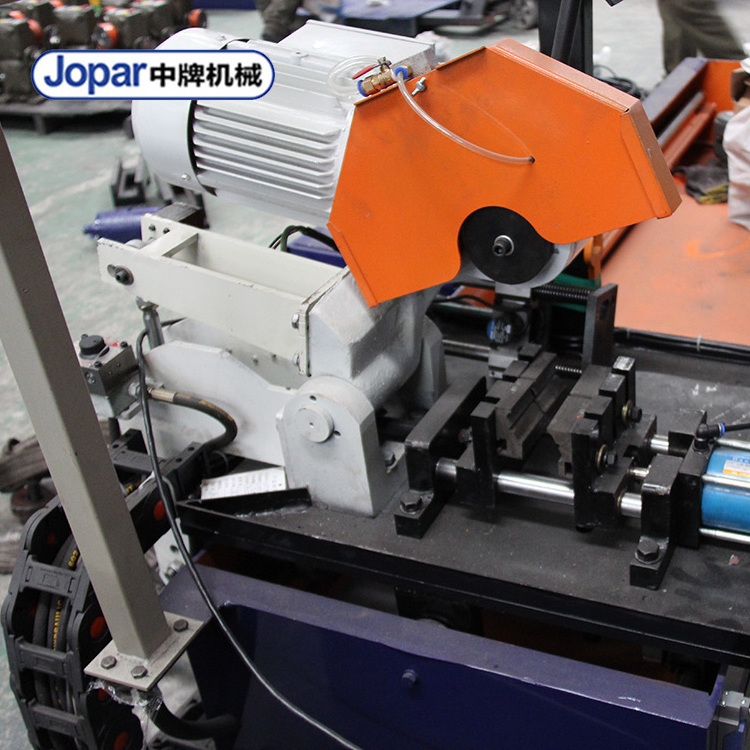

Cutting Type:

-

Metal saw cutting

-

Color:

-

Any color

-

coil Material:

-

Stainless steel / Carbon steel / Iron / Aluminum / Copper etc

-

Useful life:

-

40 Years

-

Cutting system:

-

Automatic metal saw pipe cutting machine

Quick Details

-

Pipe Material:

-

Stainless Steel,Carbon Steel,Galvanize,Iron,Steel

-

Marketing Type:

-

New Product 2021

-

Production Capacity:

-

0-12m/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jopar

-

Voltage:

-

380/415/420/440V

-

Power:

-

7.5KW+7.5KW

-

Dimension(L*W*H):

-

21.5*1.1*1.5M

-

Weight:

-

6500 kg

-

Diameter:

-

8-51mm

-

Thickness:

-

0.3-2.2mm

-

Vertical shaft:

-

25mm

-

Pipe shape:

-

Round / Square / Rectangle / Oval

-

Welding type:

-

Argon Welding

-

Cutting Type:

-

Metal saw cutting

-

Color:

-

Any color

-

coil Material:

-

Stainless steel / Carbon steel / Iron / Aluminum / Copper etc

-

Useful life:

-

40 Years

-

Cutting system:

-

Automatic metal saw pipe cutting machine

| Model | Horizontal diameter | Vertical diameter |

Diameter of pipe |

Thickness | Mail motor power | Machine size |

|

ZP-S40 |

40MM | 25MM | 8-51MM | 0.3-2.2MM | 7.5KW*7.5KW | 29*1.5M |

| ZP-S50 | 50MM | 30MM | 25-63MM | 0.4-2.5MM | 11KW*11KW | 32*1.5M |

| ZP-S60 | 60MM | 40MM | 50-114MM | 0.5-3.0MM | 15KW*15KW | 35*1.8M |

| ZP-S80 | 80MM | 50MM | 89-168MM | 0.8-4.0MM | 18.5KW*18.5KW | 40*2.5M |

| ZP-S100 | 10MM | 60MM | 114-219MM |

1.0-6.0MM |

22KW*22KW | 43*3.0M |

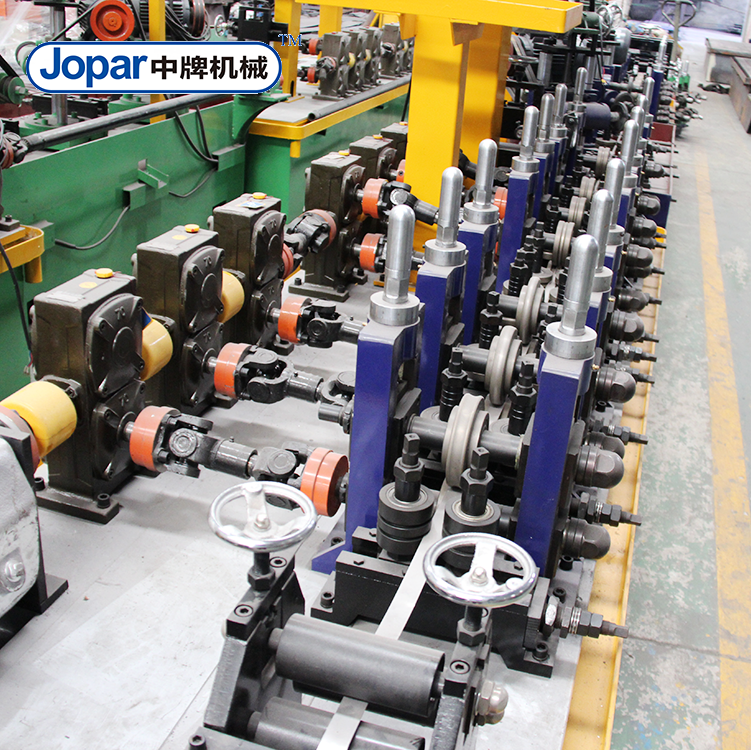

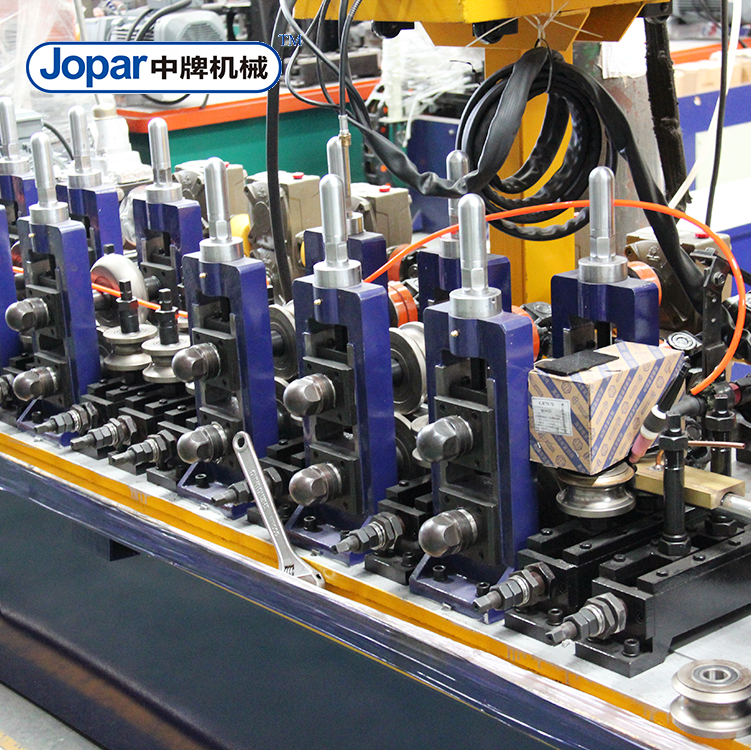

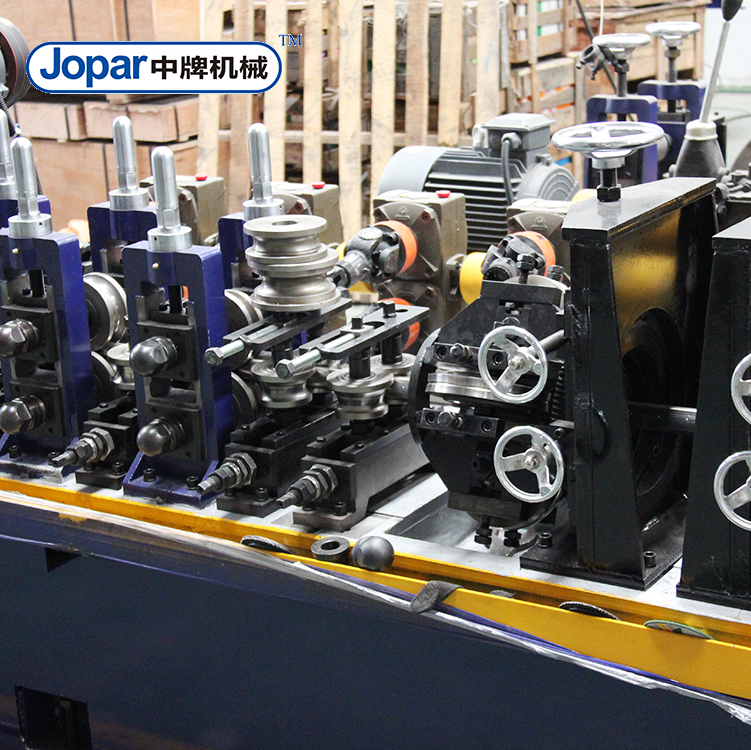

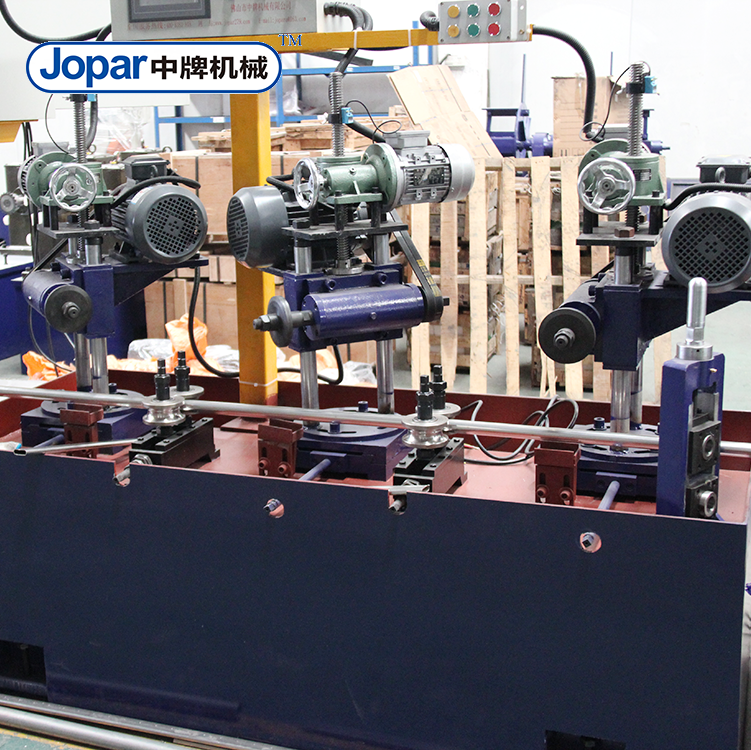

Stronger Pipe Making Machine is mainly used in the production of industrial stainless steel pipe.

Because stainless steel pipe technology matures, has been replaced in many areas seamless (such as chemicals, pharmaceuticals, wineries, oil, food, automotive, paper, air conditioning and other industries

and are widely used.)

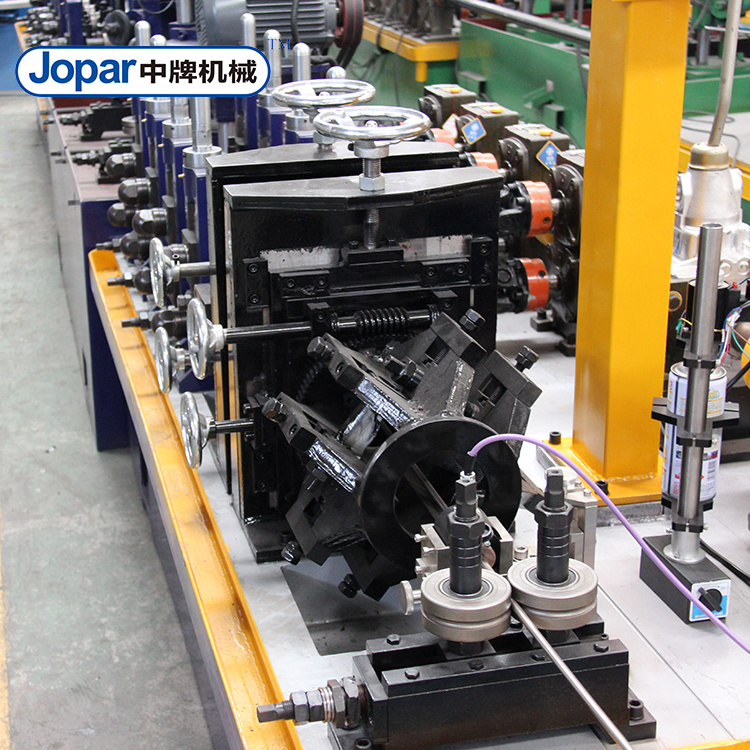

Automated production processes: the uncoiling, cleaning equipment, feed orientation, forming, welding,

weld leveling within and outside the weld grinding, shaping, sizing, solution treatment, the final sizing,

alignment, testing, spray code, length, cut off (coil), splicing and other continuous molding process.

fine structure, easy operation, manufacturing, first-class quality.

Advantage

A ; Adopt first class suppliers, like Siemens,ZhuJiang Gearbox, Dongfeng Auto Parts

B ; Adopt imported CNC machine from Taiwan, Ensure that customers can safe use

C ; Adopt high-tech. Fine motor structure design, Design, Stable performance, Save energy and environmental protection

D ; Humanized operating system design, Easy to learn, Easy operating

E ; All products pass ISO9001 international quality management system certificate, First class, Brand guarantee

F ; Jopar has 30 inventions, Practical patents, Like big tubes(168*0.35mm, 426*10mm)

D ; Our products are mainly exported to India, Japan, Thailand, Vietnam, Indonesia, Malaysia, Russia, Poland, Myanmar, Colombia and so on.