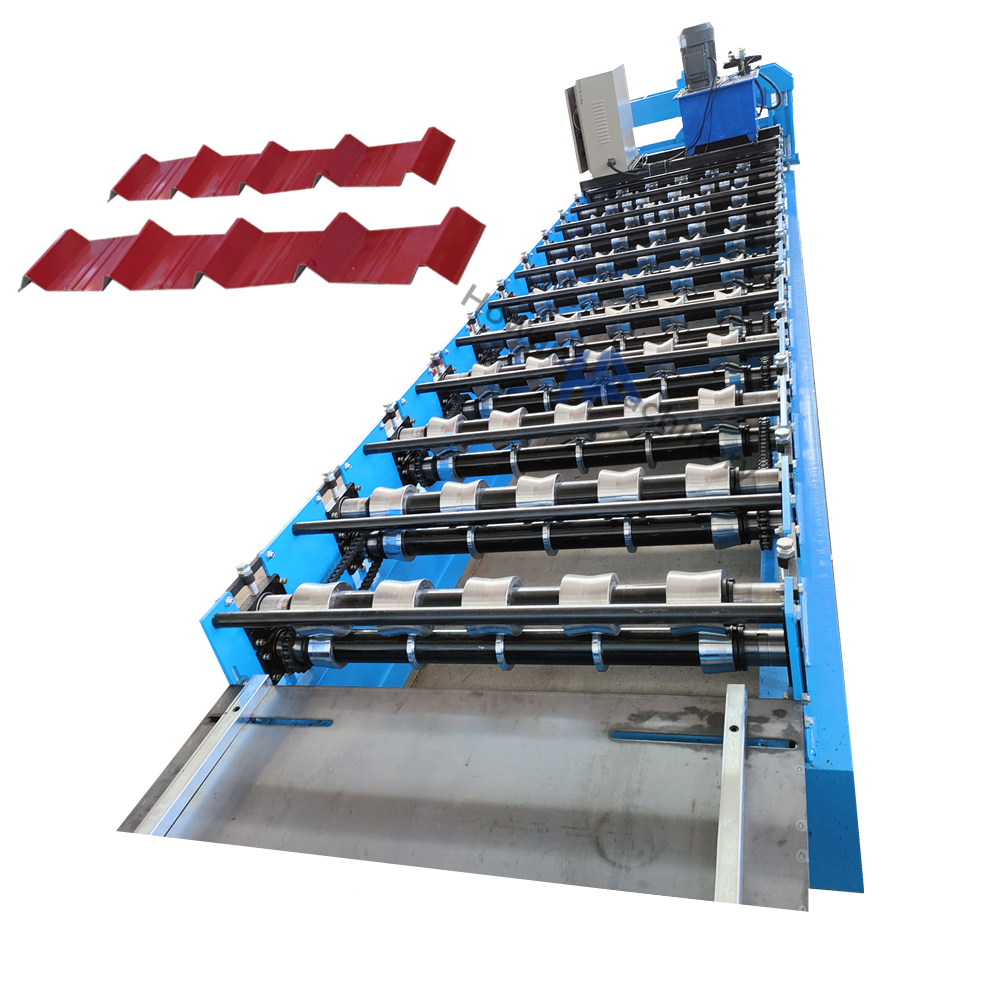

The finished products of glazed steel tile making machinery for color steel roof panels are widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibitions, family buildings, shopping malls, etc., with the advantages of beauty and classicality.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5600*1500*1500mm

-

Weight:

-

3000 kg

-

Product Name:

-

Single layer roof sheet making machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

300-450 H steel

-

Shaft diameter material:

-

Material 45#steel HB220-250

-

Decoiler:

-

5T Manual Decoiler

-

Driven System:

-

Chain Or Gear Box

-

Bottom Frame:

-

360 H Steel

-

Certification:

-

CE ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5600*1500*1500mm

-

Weight:

-

3000 kg

-

Product Name:

-

Single layer roof sheet making machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

300-450 H steel

-

Shaft diameter material:

-

Material 45#steel HB220-250

-

Decoiler:

-

5T Manual Decoiler

-

Driven System:

-

Chain Or Gear Box

-

Bottom Frame:

-

360 H Steel

-

Certification:

-

CE ISO

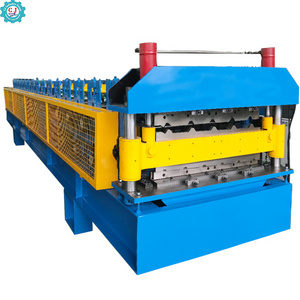

Product Details

As the manufacturer of the roll forming machinery, we can produce most of the products according to your requirements, not just the size of the products on this page.

The Working Flow

Manual uncoiler---feeding device---rolling form---speed, length, pieces set by PLC---hydraulic mold post cutting---collection table

Manual uncoiler---feeding device---rolling form---speed, length, pieces set by PLC---hydraulic mold post cutting---collection table

Usage:

It is used to expand the raw material and put it on the feeding table.

Capacity:

5T

Material:

Cr 12 High Grade Steel

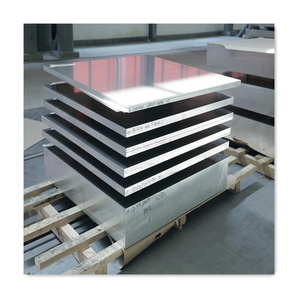

products,which is used to collect the finished products.

|

|

||

|

Product name

|

Single Layer Roof sheet making machine

|

|

|

Main motor power

|

4kW/5.5KW/7.5KW or as actual demands

|

|

|

Hydraulic motor power

|

3kW/4KW.5.5KW or as actual demands

|

|

|

Voltage

|

380V/ 3 phase/ 50 Hz (or as your requirements)

|

|

|

Control system

|

Automatic PLC control system

|

|

|

Feeding thickness

|

0.3-0.8mm

|

|

|

Cutting method

|

Hydraulic cutting

|

|

If you are interested in our products, please do not hesitate, you can contact us directly, I believe we will have a good cooperation.

Details Images

As many different shapes roofing sheets,the roofing sheet shape customized.This is just for your reference of one set we sold before.

For this roof press making machine, we have below advantage:

1.We choose a innovative way that already solved the glazed tile press step distance problem.

That method can ensure the each finished glazed tile will in a same distance step and can be well overlap one by one together.

2.This can save you a lot of money and time for you about this problem.

3. We are focus on machine detail design, will use many years experience to supplement the machine details and avoid some problems.Will improve the machine service life.

Why Choose Us

Hot Searches