- Product Details

- {{item.text}}

Quick Details

-

Application:

-

roof insulation

-

Design Style:

-

waterproof

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PEGASUSWINGS

-

Model Number:

-

CR1210

-

Type:

-

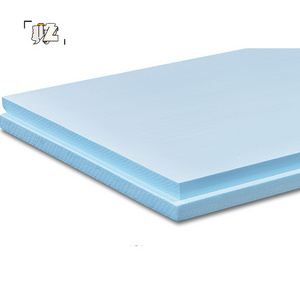

XPS Foam Boards

-

Thermal conductivity:

-

0.027-0.036w/mk

-

Color:

-

pink,bule,green

-

Length:

-

1200mm/1250mm/6000mm

-

Thickness:

-

20-100mm

-

Size:

-

customized

-

Compressive strength:

-

350-700Kpa

-

Density:

-

32-45 Kg/m3

-

Temperature limits:

-

-50℃,+75℃

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

roof insulation

-

Design Style:

-

waterproof

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PEGASUSWINGS

-

Model Number:

-

CR1210

-

Type:

-

XPS Foam Boards

-

Thermal conductivity:

-

0.027-0.036w/mk

-

Color:

-

pink,bule,green

-

Length:

-

1200mm/1250mm/6000mm

-

Thickness:

-

20-100mm

-

Size:

-

customized

-

Compressive strength:

-

350-700Kpa

-

Density:

-

32-45 Kg/m3

-

Temperature limits:

-

-50℃,+75℃

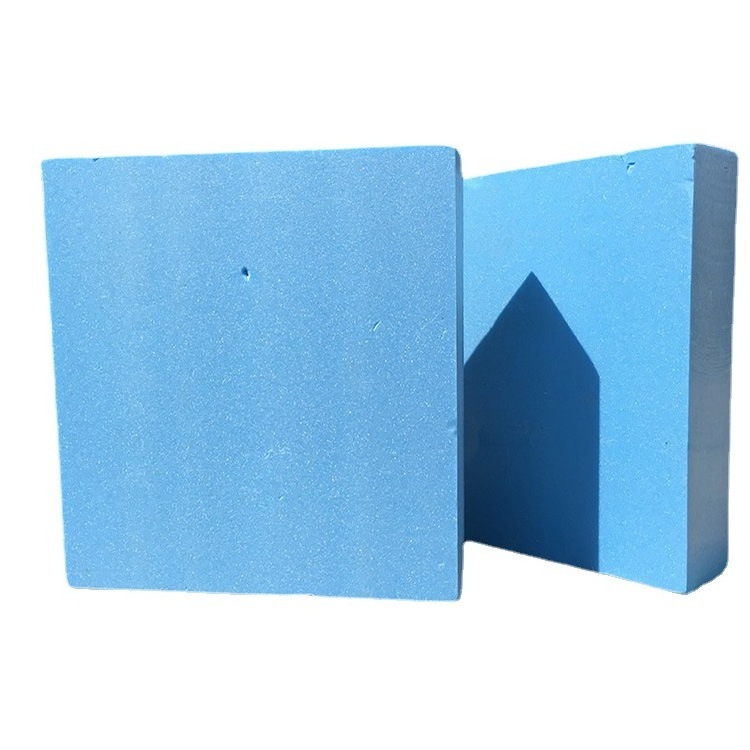

XPS Foam Board

XPS stands for Extruded Polystyrene. XPS foam board is essentially liquified then molded and compressed styrofoam. Ever grab your Dunkin' Donuts coffee and not get burned? Well the hot coffee is kept from scalding your mitts by 1/4" of polystyrene foam. Imagine how well 2 or 4 inches would insulate (Answer: much better).

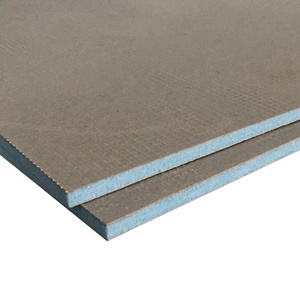

XPS foam board is an insulation material similar to polyisocyanurate in its texture and rigidity. It is usually blue or pink in color, with a smooth plastic surface. Like fiberglass, the pink and blue colors are not natural but part of the manufacturing company's marketing efforts.

* Stable performance and anti-aging:

The extruded polystyrene(xps) insulation boards can be used 35-50 years.

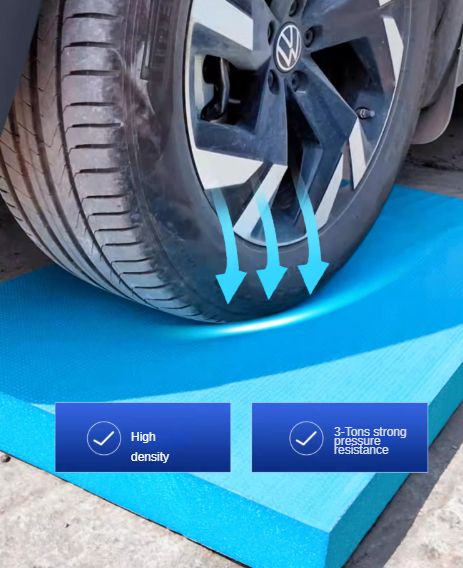

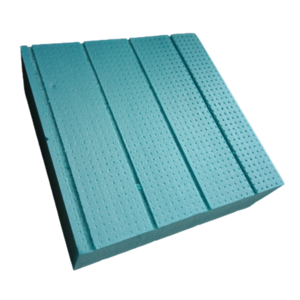

* Resistance to compression:

with other thermal insulation material(200kpa for EPS), it has better compressive strength (around 300kpa), which make it the ideal solution for heavy domestic or industrial loads.

* Water resistance:

Polyfoam is almost 100% closed cell and as such is unaffected by moisture.

* Lightweight:

volume optimization and easy to handle

* Resistance to deformation

* Resistance to impact

* Versatile:

the closed cell structure and density of polyfoam allow specific edfe details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape.

* Excellent sound insulation:

12mm board,20 db

* Environment friendly:

Free of CFC & HCFC

* Easy to be tiled

* Recycled:

Polyfoam can be 100% recycled

XPS foam board has value in many building and insulating applications, especially in harsh environments. XPS is suitable for cold storage, insulating below slabs and slab edges, insulating foundation or cellar walls and exterior sheathing as part of the building shell. It provides water resistant layers and its durability ensures good long term payback.

Finally, XPS is widely used in weatherization work in conjunction with caulking and foam guns. Weatherization crew use XPS to help air seal soffits, insulate sill plates and seal leaky attic spaces.

Outside the insulation/auditing industry, XPS/Polystyrene is used for surf boards, manufacturing hobby models, creating architectural miniature models and of course Dunkin' Donuts coffee cups.

|

Density

|

Kg/m3

|

35-45

|

|

Thermal conductivity,90days,10℃

|

W/(m*k)

|

0.027-0.036

|

|

Compressive strength at 10% deflection or yield,(vertical)

|

Kpa

|

250-700

|

|

Tensile strength

|

kpa

|

≥350

|

|

Water absorption

|

Vol-%

|

≤1.00%

|

|

Capilarity

|

nil

|

nil

|

|

Coefficient of linear thermal expansion

|

mm(m*K)

|

0.07

|

|

Temperature limits

|

℃

|

-50℃,+75℃

|

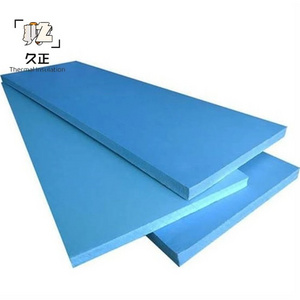

Available Sizes:

|

Thickness

|

Width

|

Length

|

Edge

|

|

60-100mm

|

600mm

|

|

Square Edge

|

|

20-100mm

|

600mm

|

|

Ship Lap,

Square Edge,

Tongue&Grooved

|

|

20-100mm

|

|

|

|

|

20-100mm

|

1200mm

|

|

|