- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Cup respirators making machine

-

Power:

-

9000 W

-

Dimension(L*W*H):

-

9600*1600*1850mm

-

Weight:

-

3 KG

-

Production Capacity:

-

0-24pc/min

Quick Details

-

Voltage:

-

220V

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Cup respirators making machine

-

Power:

-

9000 W

-

Dimension(L*W*H):

-

9600*1600*1850mm

-

Weight:

-

3 KG

-

Production Capacity:

-

0-24pc/min

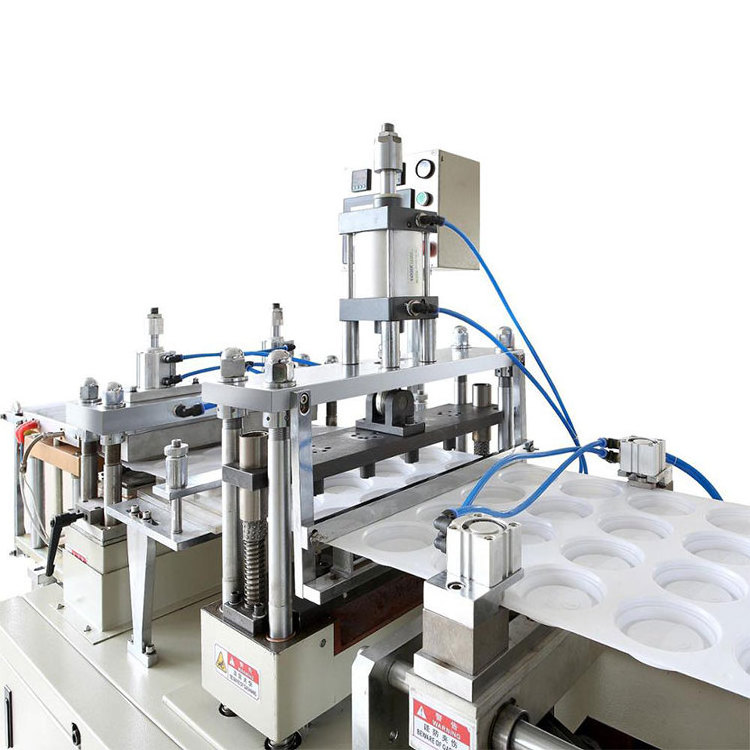

Cup Respirators Making Machine

1. Product features:

This Cup Mask Auto-line is used for producing cup masks with overall automation. Its main processes includes 3-6 layers of PP spunbond and filtration non woven fabric rolls feeding and heat welding, cup mask body molding, positioning and logo printing, aluminum nose clip feeding and welding, ear-loop welding, breather valve hole punching and finished cup mask discharging. The process won’t cause any damage to the properties of each fabric layer. The finished cup masks are applicable for high pollution industry and meet the N95/99 or FFP2/3 standard.

We have different choices of machine as following:

- Full automatic machine;

- Half automatic machine;

- Manual machine;

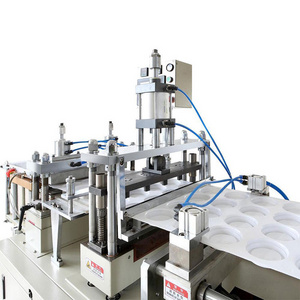

2. Technical process:

- Cup mask hot molding: To make cup mask body automatically from needling non woven fabric feeding & pulling, hot molding.

- Cutting: To cut the spun bond non woven fabric and melt blown non woven fabric into required size.

- Welding and cutting: To form the cup mask body, weld the multi-layer fabrics and cut the scrap edge.

- Cup mask making machine: Aluminum nose bar, head loop welding, pad printing, hole punching and breather valve welding.

3. Technical specificaton:

| No. | Parameter | Specification |

| 1 | Machine size | 9600(L)*1600(W)*1850(H) |

| 2 | Driving motion | Servo motor |

| 3 | Electric control | Mitsubishi PLC |

| 4 | Control panel | Touch screen and button |

| 5 | Power source | 220V, 50/60HZ |

| 6 | Material application | PP spunbond, Melt blown, Static cotton, Needle-punched cotton |

| 7 | Product size | Customization |

| 8 | Capacity | 20-24pc/min |

| 9 | Remark | Different shape and cup masks can be produced by changing molds. |

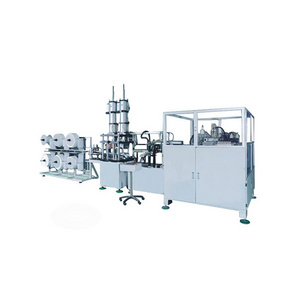

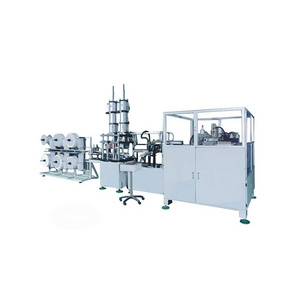

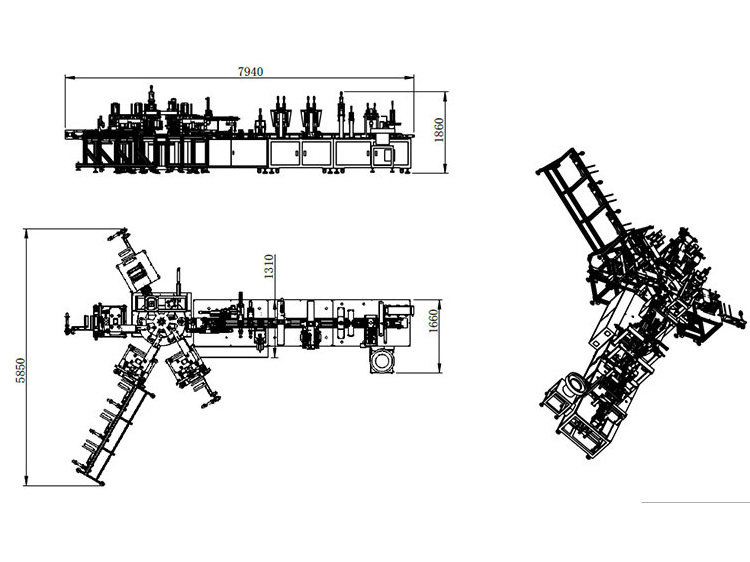

4. Layout drawing of full automatic machine:

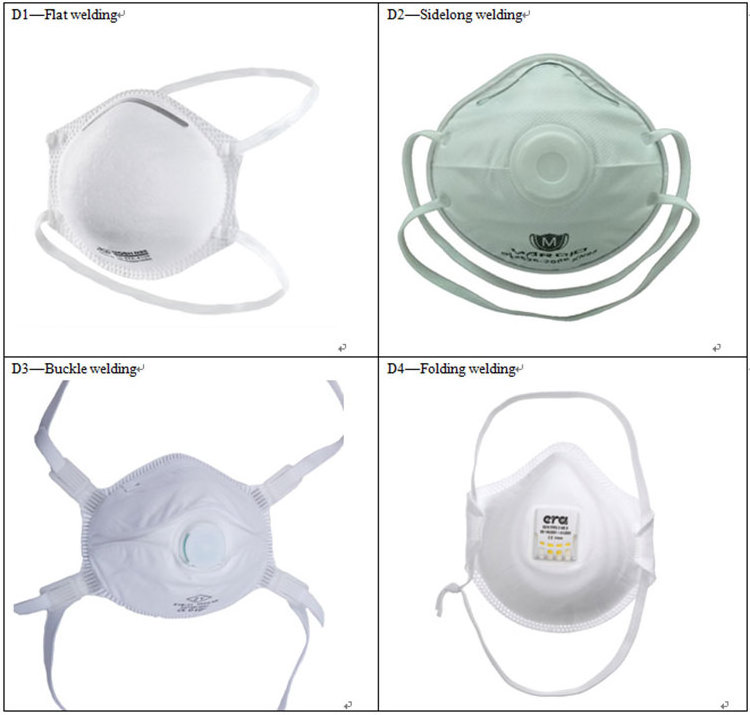

5. Different machines for different masks:

Generally speaking, we can classify cup shape masks into four series:

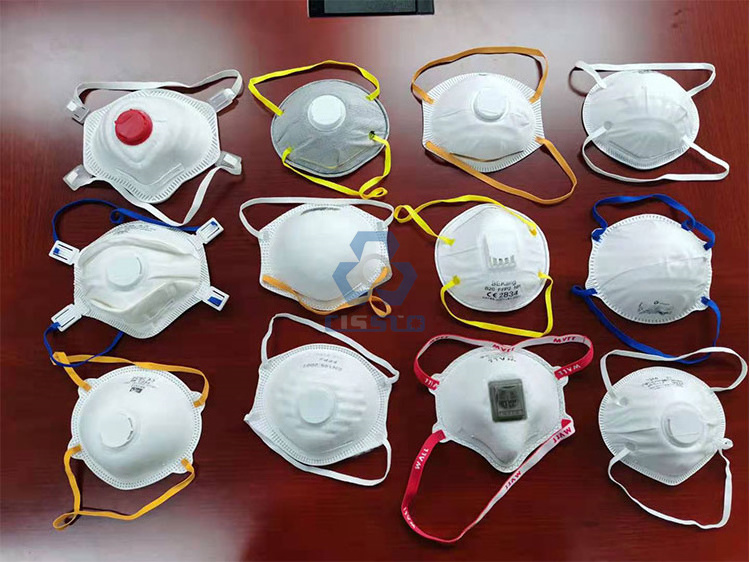

6. Machine photos:

7.Machine installation: